Are you a seasoned Molding Cutter seeking a new career path? Discover our professionally built Molding Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

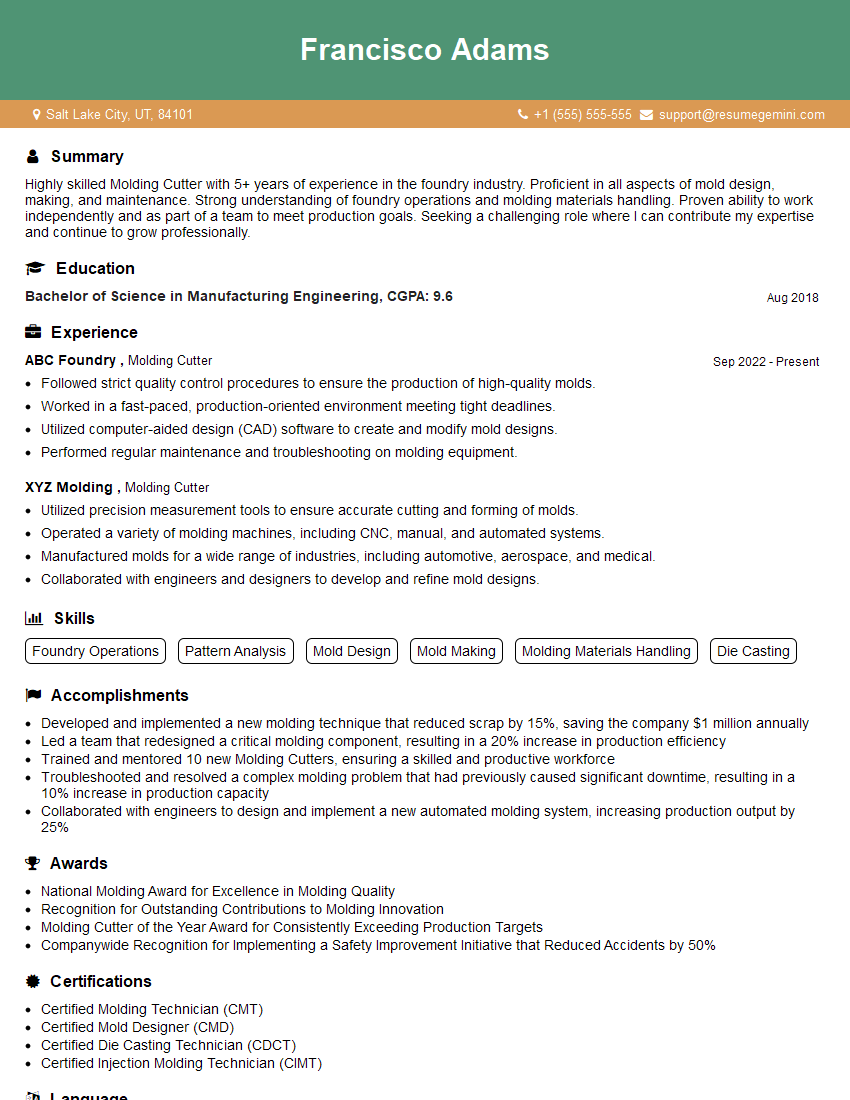

Francisco Adams

Molding Cutter

Summary

Highly skilled Molding Cutter with 5+ years of experience in the foundry industry. Proficient in all aspects of mold design, making, and maintenance. Strong understanding of foundry operations and molding materials handling. Proven ability to work independently and as part of a team to meet production goals. Seeking a challenging role where I can contribute my expertise and continue to grow professionally.

Education

Bachelor of Science in Manufacturing Engineering

August 2018

Skills

- Foundry Operations

- Pattern Analysis

- Mold Design

- Mold Making

- Molding Materials Handling

- Die Casting

Work Experience

Molding Cutter

- Followed strict quality control procedures to ensure the production of high-quality molds.

- Worked in a fast-paced, production-oriented environment meeting tight deadlines.

- Utilized computer-aided design (CAD) software to create and modify mold designs.

- Performed regular maintenance and troubleshooting on molding equipment.

Molding Cutter

- Utilized precision measurement tools to ensure accurate cutting and forming of molds.

- Operated a variety of molding machines, including CNC, manual, and automated systems.

- Manufactured molds for a wide range of industries, including automotive, aerospace, and medical.

- Collaborated with engineers and designers to develop and refine mold designs.

Accomplishments

- Developed and implemented a new molding technique that reduced scrap by 15%, saving the company $1 million annually

- Led a team that redesigned a critical molding component, resulting in a 20% increase in production efficiency

- Trained and mentored 10 new Molding Cutters, ensuring a skilled and productive workforce

- Troubleshooted and resolved a complex molding problem that had previously caused significant downtime, resulting in a 10% increase in production capacity

- Collaborated with engineers to design and implement a new automated molding system, increasing production output by 25%

Awards

- National Molding Award for Excellence in Molding Quality

- Recognition for Outstanding Contributions to Molding Innovation

- Molding Cutter of the Year Award for Consistently Exceeding Production Targets

- Companywide Recognition for Implementing a Safety Improvement Initiative that Reduced Accidents by 50%

Certificates

- Certified Molding Technician (CMT)

- Certified Mold Designer (CMD)

- Certified Die Casting Technician (CDCT)

- Certified Injection Molding Technician (CIMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Molding Cutter

- Highlight your experience in mold design and making, using specific examples to demonstrate your skills.

- Quantify your accomplishments whenever possible, using metrics to show the impact of your work.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the specific role.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Molding Cutter Resume

- Designed and created molds using various materials, including sand, metal, and plastic

- Analyzed patterns to determine molding parameters and ensure mold accuracy

- Operated molding machines and equipment to produce high-quality molds

- Handled and maintained molding materials, ensuring proper storage and usage

- Troubleshooted and resolved molding issues to maintain production efficiency

- Collaborated with engineers and other team members to optimize mold design and production processes

- Adhered to safety protocols and maintained a clean and organized work environment

Frequently Asked Questions (FAQ’s) For Molding Cutter

What is the role of a Molding Cutter?

A Molding Cutter is responsible for designing, creating, and maintaining molds used in the casting process. They analyze patterns, select appropriate molding materials, and operate molding machines to produce high-quality molds. Molding Cutters also troubleshoot and resolve molding issues to ensure production efficiency.

What are the key skills required for a Molding Cutter?

Key skills for a Molding Cutter include foundry operations, pattern analysis, mold design, mold making, molding materials handling, die casting, and quality control.

What is the average salary for a Molding Cutter?

The average salary for a Molding Cutter in the United States is around $50,000 per year.

What are the career advancement opportunities for a Molding Cutter?

Molding Cutters with experience and expertise can advance to roles such as Molding Supervisor, Foundry Manager, or Quality Control Manager.

What is the job outlook for Molding Cutters?

The job outlook for Molding Cutters is expected to be stable in the coming years, with growth in industries such as automotive, aerospace, and construction.

What are the educational requirements for a Molding Cutter?

Most Molding Cutters have a high school diploma or equivalent, with some employers preferring candidates with a technical degree or certification in a related field.

What are the certifications available for Molding Cutters?

There are several certifications available for Molding Cutters, including the Certified Molding Technician (CMT) certification from the American Foundry Society (AFS) and the Certified Mold Maker (CMM) certification from the National Tooling and Machining Association (NTMA).

What are the professional organizations for Molding Cutters?

Professional organizations for Molding Cutters include the American Foundry Society (AFS) and the National Tooling and Machining Association (NTMA).