Are you a seasoned Furnace Process Plant Operator seeking a new career path? Discover our professionally built Furnace Process Plant Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

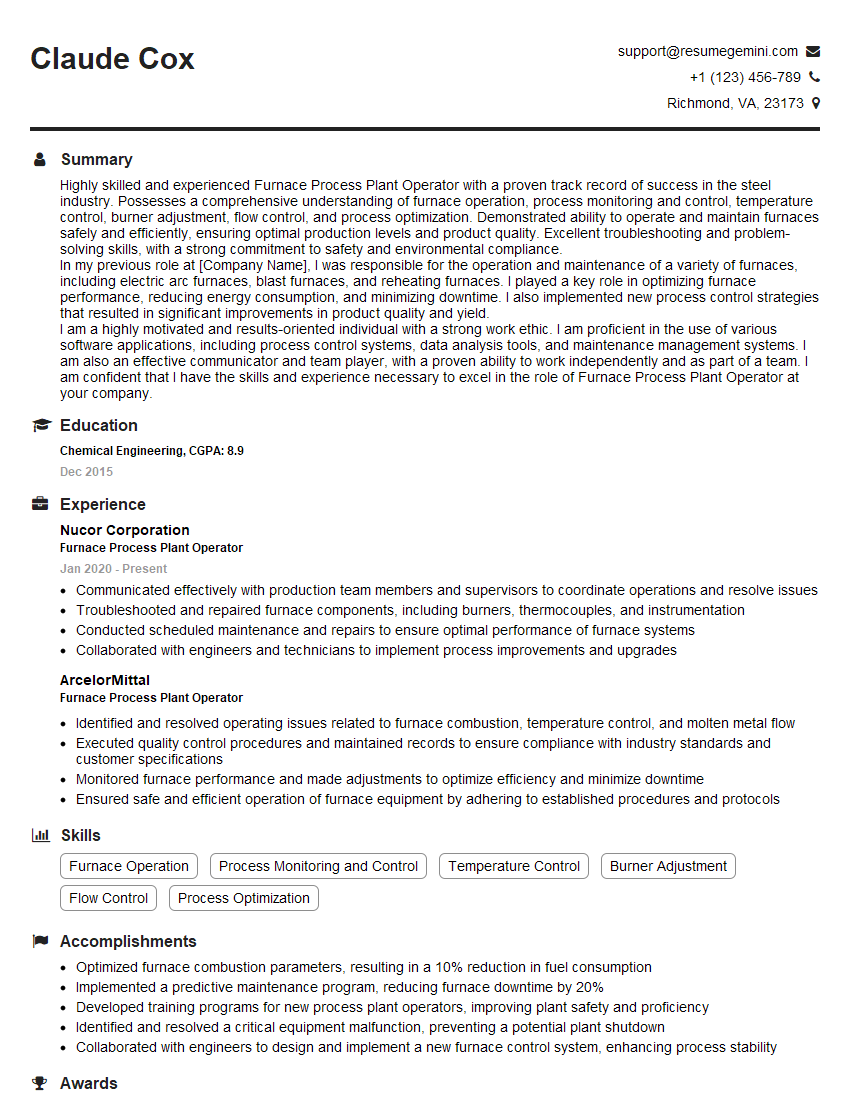

Claude Cox

Furnace Process Plant Operator

Summary

Highly skilled and experienced Furnace Process Plant Operator with a proven track record of success in the steel industry. Possesses a comprehensive understanding of furnace operation, process monitoring and control, temperature control, burner adjustment, flow control, and process optimization. Demonstrated ability to operate and maintain furnaces safely and efficiently, ensuring optimal production levels and product quality. Excellent troubleshooting and problem-solving skills, with a strong commitment to safety and environmental compliance.

In my previous role at [Company Name], I was responsible for the operation and maintenance of a variety of furnaces, including electric arc furnaces, blast furnaces, and reheating furnaces. I played a key role in optimizing furnace performance, reducing energy consumption, and minimizing downtime. I also implemented new process control strategies that resulted in significant improvements in product quality and yield.

I am a highly motivated and results-oriented individual with a strong work ethic. I am proficient in the use of various software applications, including process control systems, data analysis tools, and maintenance management systems. I am also an effective communicator and team player, with a proven ability to work independently and as part of a team. I am confident that I have the skills and experience necessary to excel in the role of Furnace Process Plant Operator at your company.

Education

Chemical Engineering

December 2015

Skills

- Furnace Operation

- Process Monitoring and Control

- Temperature Control

- Burner Adjustment

- Flow Control

- Process Optimization

Work Experience

Furnace Process Plant Operator

- Communicated effectively with production team members and supervisors to coordinate operations and resolve issues

- Troubleshooted and repaired furnace components, including burners, thermocouples, and instrumentation

- Conducted scheduled maintenance and repairs to ensure optimal performance of furnace systems

- Collaborated with engineers and technicians to implement process improvements and upgrades

Furnace Process Plant Operator

- Identified and resolved operating issues related to furnace combustion, temperature control, and molten metal flow

- Executed quality control procedures and maintained records to ensure compliance with industry standards and customer specifications

- Monitored furnace performance and made adjustments to optimize efficiency and minimize downtime

- Ensured safe and efficient operation of furnace equipment by adhering to established procedures and protocols

Accomplishments

- Optimized furnace combustion parameters, resulting in a 10% reduction in fuel consumption

- Implemented a predictive maintenance program, reducing furnace downtime by 20%

- Developed training programs for new process plant operators, improving plant safety and proficiency

- Identified and resolved a critical equipment malfunction, preventing a potential plant shutdown

- Collaborated with engineers to design and implement a new furnace control system, enhancing process stability

Awards

- Safety Award for maintaining an accidentfree workplace for consecutive years

- Process Excellence Award for developing and implementing a new process that increased furnace efficiency by 15%

- Technical Achievement Award for innovative solutions in furnace operations

Certificates

- Furnace Operator Certification (FOC)

- Industrial Process Control (IPC) Certification

- OSHA Safety Certification

- API 510 Pressure Vessel Inspector Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Furnace Process Plant Operator

- Highlight your experience in operating and maintaining furnaces, including the specific types of furnaces you have worked with.

- Quantify your accomplishments whenever possible, such as reducing energy consumption by a certain percentage or improving product quality by a specific amount.

- Demonstrate your understanding of furnace process control systems and your ability to troubleshoot and resolve furnace malfunctions.

- Emphasize your commitment to safety and environmental compliance.

- Proofread your resume carefully before submitting it to ensure that it is free of errors.

Essential Experience Highlights for a Strong Furnace Process Plant Operator Resume

- Operate and monitor furnaces to maintain optimal temperature and flow conditions.

- Adjust burner settings and flow rates to ensure proper combustion and heat distribution.

- Monitor and control process parameters, such as temperature, pressure, and flow rates, to ensure product quality and process efficiency.

- Troubleshoot and resolve furnace malfunctions, including burner issues, temperature deviations, and flow disruptions.

- Perform routine maintenance and repairs on furnaces, including cleaning, lubrication, and replacement of parts.

- Follow established safety procedures and environmental regulations to ensure a safe and compliant work environment.

- Maintain accurate records of furnace operation and maintenance activities.

Frequently Asked Questions (FAQ’s) For Furnace Process Plant Operator

What are the key responsibilities of a Furnace Process Plant Operator?

The key responsibilities of a Furnace Process Plant Operator include operating and monitoring furnaces to maintain optimal temperature and flow conditions, adjusting burner settings and flow rates to ensure proper combustion and heat distribution, monitoring and controlling process parameters to ensure product quality and process efficiency, troubleshooting and resolving furnace malfunctions, performing routine maintenance and repairs on furnaces, following established safety procedures and environmental regulations, and maintaining accurate records of furnace operation and maintenance activities.

What are the qualifications for becoming a Furnace Process Plant Operator?

The qualifications for becoming a Furnace Process Plant Operator typically include a high school diploma or equivalent, with some employers preferring candidates with a degree in chemical engineering or a related field. Prior experience in operating and maintaining furnaces is also typically required, along with a strong understanding of furnace process control systems and safety procedures.

What is the work environment of a Furnace Process Plant Operator like?

The work environment of a Furnace Process Plant Operator can be hot, noisy, and dirty. Operators may be exposed to fumes, gases, and other hazardous materials, and they may have to work in confined spaces. They may also be required to work overtime or on weekends.

What is the career outlook for Furnace Process Plant Operators?

The career outlook for Furnace Process Plant Operators is expected to be good over the next few years. As the demand for steel and other metals continues to grow, so too will the demand for Furnace Process Plant Operators. However, competition for jobs may be strong, and those with the most experience and training will have the best job prospects.

What are the salary expectations for Furnace Process Plant Operators?

The salary expectations for Furnace Process Plant Operators can vary depending on their experience, location, and employer. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Furnace Operators and Tenders was $54,490 in May 2021.

What are the advancement opportunities for Furnace Process Plant Operators?

The advancement opportunities for Furnace Process Plant Operators can vary depending on their employer and their own individual goals and ambitions. Some Furnace Process Plant Operators may be able to advance to positions such as Supervisor or Manager, while others may choose to specialize in a particular area of furnace operation or maintenance.

What are the benefits of working as a Furnace Process Plant Operator?

The benefits of working as a Furnace Process Plant Operator can include a competitive salary, good benefits, and the opportunity to work in a challenging and rewarding environment. Furnace Process Plant Operators also have the opportunity to learn about a variety of different industrial processes and to develop valuable skills that can be used in other industries.

What are the challenges of working as a Furnace Process Plant Operator?

The challenges of working as a Furnace Process Plant Operator can include working in a hot, noisy, and dirty environment, being exposed to fumes, gases, and other hazardous materials, and having to work in confined spaces. Furnace Process Plant Operators may also be required to work overtime or on weekends.