Are you a seasoned Hydrotreater Operator seeking a new career path? Discover our professionally built Hydrotreater Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

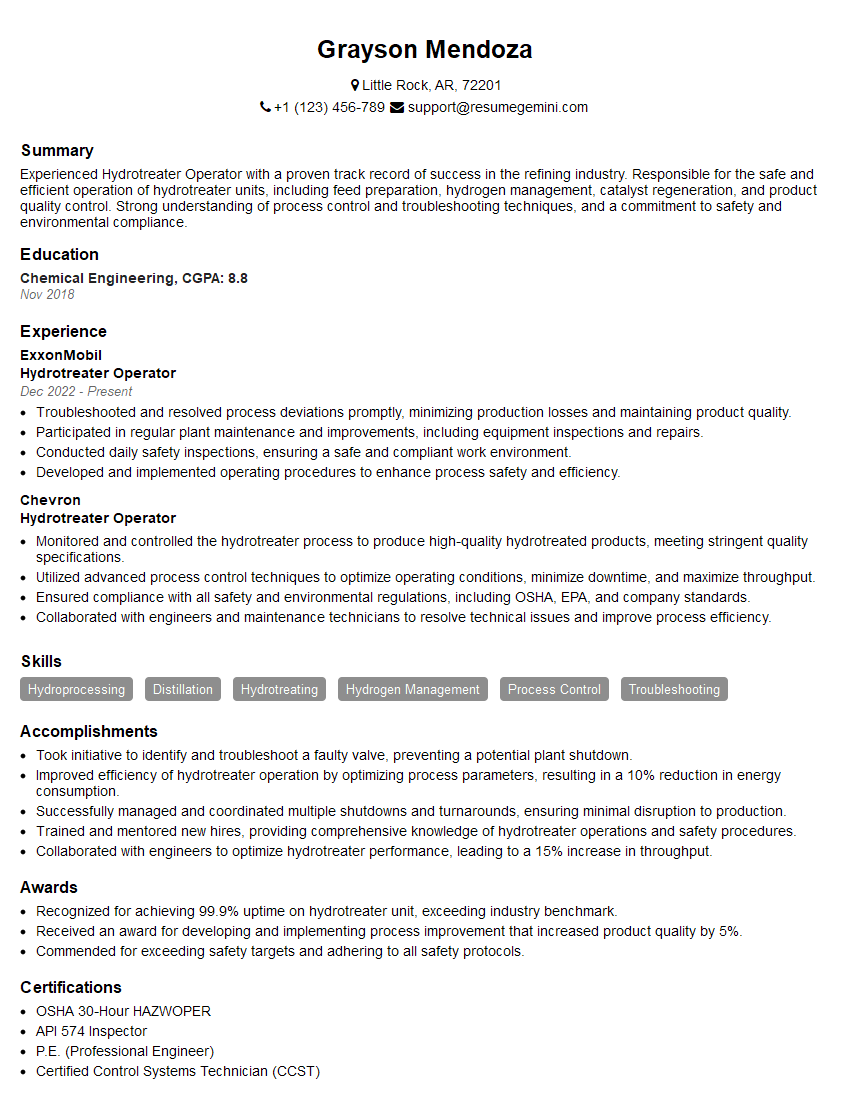

Grayson Mendoza

Hydrotreater Operator

Summary

Experienced Hydrotreater Operator with a proven track record of success in the refining industry. Responsible for the safe and efficient operation of hydrotreater units, including feed preparation, hydrogen management, catalyst regeneration, and product quality control. Strong understanding of process control and troubleshooting techniques, and a commitment to safety and environmental compliance.

Education

Chemical Engineering

November 2018

Skills

- Hydroprocessing

- Distillation

- Hydrotreating

- Hydrogen Management

- Process Control

- Troubleshooting

Work Experience

Hydrotreater Operator

- Troubleshooted and resolved process deviations promptly, minimizing production losses and maintaining product quality.

- Participated in regular plant maintenance and improvements, including equipment inspections and repairs.

- Conducted daily safety inspections, ensuring a safe and compliant work environment.

- Developed and implemented operating procedures to enhance process safety and efficiency.

Hydrotreater Operator

- Monitored and controlled the hydrotreater process to produce high-quality hydrotreated products, meeting stringent quality specifications.

- Utilized advanced process control techniques to optimize operating conditions, minimize downtime, and maximize throughput.

- Ensured compliance with all safety and environmental regulations, including OSHA, EPA, and company standards.

- Collaborated with engineers and maintenance technicians to resolve technical issues and improve process efficiency.

Accomplishments

- Took initiative to identify and troubleshoot a faulty valve, preventing a potential plant shutdown.

- Improved efficiency of hydrotreater operation by optimizing process parameters, resulting in a 10% reduction in energy consumption.

- Successfully managed and coordinated multiple shutdowns and turnarounds, ensuring minimal disruption to production.

- Trained and mentored new hires, providing comprehensive knowledge of hydrotreater operations and safety procedures.

- Collaborated with engineers to optimize hydrotreater performance, leading to a 15% increase in throughput.

Awards

- Recognized for achieving 99.9% uptime on hydrotreater unit, exceeding industry benchmark.

- Received an award for developing and implementing process improvement that increased product quality by 5%.

- Commended for exceeding safety targets and adhering to all safety protocols.

Certificates

- OSHA 30-Hour HAZWOPER

- API 574 Inspector

- P.E. (Professional Engineer)

- Certified Control Systems Technician (CCST)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hydrotreater Operator

- Highlight your experience with hydroprocessing and hydrotreating technologies.

- Quantify your accomplishments with specific metrics whenever possible.

- Demonstrate your understanding of process control and troubleshooting techniques.

- Emphasize your commitment to safety and environmental compliance.

Essential Experience Highlights for a Strong Hydrotreater Operator Resume

- Operate and monitor hydrotreater units to meet production targets and product specifications.

- Manage hydrogen flow rates and pressures to optimize process conditions.

- Monitor and troubleshoot process parameters to identify and correct deviations.

- Perform catalyst regeneration and maintenance tasks to ensure optimal performance.

- Maintain accurate records and reports related to process operations and equipment performance.

- Comply with all safety and environmental regulations and procedures.

- Communicate effectively with colleagues and supervisors to ensure smooth operations.

Frequently Asked Questions (FAQ’s) For Hydrotreater Operator

What is the role of a Hydrotreater Operator?

A Hydrotreater Operator is responsible for the safe and efficient operation of hydrotreater units in a refinery. They monitor and control process conditions, troubleshoot problems, and perform maintenance to ensure that the unit is operating at optimal performance levels.

What are the qualifications for a Hydrotreater Operator?

Typically, a Hydrotreater Operator has a degree in chemical engineering or a related field. They should also have experience with hydroprocessing and hydrotreating technologies, as well as a strong understanding of process control and troubleshooting techniques.

What are the key responsibilities of a Hydrotreater Operator?

The key responsibilities of a Hydrotreater Operator include operating and monitoring hydrotreater units, managing hydrogen flow rates and pressures, monitoring and troubleshooting process parameters, and performing catalyst regeneration and maintenance tasks.

What are the career prospects for a Hydrotreater Operator?

Hydrotreater Operators can advance to positions such as Process Engineer, Production Supervisor, or Plant Manager. With additional education and experience, they can also move into management roles.

What is the average salary for a Hydrotreater Operator?

The average salary for a Hydrotreater Operator is around $75,000 per year. However, salaries can vary depending on experience, location, and company size.

What are the working conditions for a Hydrotreater Operator?

Hydrotreater Operators typically work in a refinery setting. They may be exposed to hazardous chemicals and noise, and they may have to work in confined spaces.