Are you a seasoned Plant Operator Control Room Operator seeking a new career path? Discover our professionally built Plant Operator Control Room Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

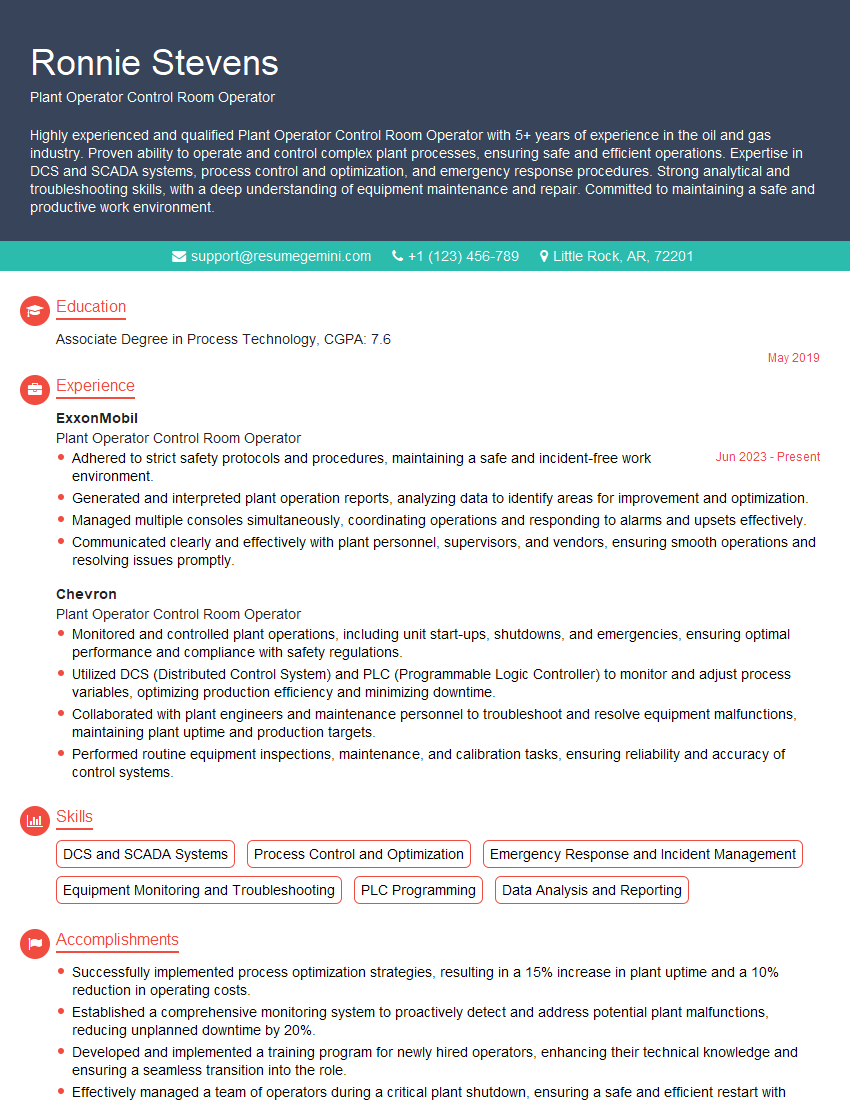

Ronnie Stevens

Plant Operator Control Room Operator

Summary

Highly experienced and qualified Plant Operator Control Room Operator with 5+ years of experience in the oil and gas industry. Proven ability to operate and control complex plant processes, ensuring safe and efficient operations. Expertise in DCS and SCADA systems, process control and optimization, and emergency response procedures. Strong analytical and troubleshooting skills, with a deep understanding of equipment maintenance and repair. Committed to maintaining a safe and productive work environment.

Education

Associate Degree in Process Technology

May 2019

Skills

- DCS and SCADA Systems

- Process Control and Optimization

- Emergency Response and Incident Management

- Equipment Monitoring and Troubleshooting

- PLC Programming

- Data Analysis and Reporting

Work Experience

Plant Operator Control Room Operator

- Adhered to strict safety protocols and procedures, maintaining a safe and incident-free work environment.

- Generated and interpreted plant operation reports, analyzing data to identify areas for improvement and optimization.

- Managed multiple consoles simultaneously, coordinating operations and responding to alarms and upsets effectively.

- Communicated clearly and effectively with plant personnel, supervisors, and vendors, ensuring smooth operations and resolving issues promptly.

Plant Operator Control Room Operator

- Monitored and controlled plant operations, including unit start-ups, shutdowns, and emergencies, ensuring optimal performance and compliance with safety regulations.

- Utilized DCS (Distributed Control System) and PLC (Programmable Logic Controller) to monitor and adjust process variables, optimizing production efficiency and minimizing downtime.

- Collaborated with plant engineers and maintenance personnel to troubleshoot and resolve equipment malfunctions, maintaining plant uptime and production targets.

- Performed routine equipment inspections, maintenance, and calibration tasks, ensuring reliability and accuracy of control systems.

Accomplishments

- Successfully implemented process optimization strategies, resulting in a 15% increase in plant uptime and a 10% reduction in operating costs.

- Established a comprehensive monitoring system to proactively detect and address potential plant malfunctions, reducing unplanned downtime by 20%.

- Developed and implemented a training program for newly hired operators, enhancing their technical knowledge and ensuring a seamless transition into the role.

- Effectively managed a team of operators during a critical plant shutdown, ensuring a safe and efficient restart with minimal disruption to production.

- Identified and resolved a complex technical issue with the plants automation system, preventing a potential equipment failure and ensuring continued plant operation.

Awards

- Received the Plant Operator of the Year award for outstanding performance and contributions to plant operations.

- Recognized for superior performance in maintaining plant efficiency and safety, earning the Excellence in Control Room Operations award.

- Recognized for exceptional troubleshooting skills and quick decisionmaking during an emergency plant situation, preventing a major incident.

- Received the Plant Operator of the Quarter award for consistently achieving outstanding performance and exceeding expectations.

Certificates

- Certified Control Room Operator (CCRO)

- ISA Certified Automation Professional (CAP)

- OSHA 40Hour HAZWOPER

- NFPA 70E Electrical Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plant Operator Control Room Operator

- – Tailor your resume to each specific job you apply for.

- – Highlight your skills and experience that are most relevant to the job.

- – Use strong action verbs and quantify your accomplishments.

- – Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Plant Operator Control Room Operator Resume

- – Monitored and controlled plant processes using DCS and SCADA systems

- – Ensured compliance with safety and environmental regulations

- – Analyzed process data and identified areas for optimization

- – Responded to and resolved equipment malfunctions and process upsets

- – Provided technical support and guidance to other operators

- – Maintained accurate records and documentation

- – Contributed to continuous improvement initiatives

Frequently Asked Questions (FAQ’s) For Plant Operator Control Room Operator

What is the role of a Plant Operator Control Room Operator?

A Plant Operator Control Room Operator is responsible for monitoring and controlling plant processes using DCS and SCADA systems. They ensure compliance with safety and environmental regulations, analyze process data and identify areas for optimization, and respond to and resolve equipment malfunctions and process upsets.

What are the key skills required for a Plant Operator Control Room Operator?

Key skills for a Plant Operator Control Room Operator include expertise in DCS and SCADA systems, process control and optimization, and emergency response procedures. Strong analytical and troubleshooting skills, with a deep understanding of equipment maintenance and repair, are also essential.

What is the career outlook for Plant Operator Control Room Operators?

The career outlook for Plant Operator Control Room Operators is expected to be good over the next few years. The increased demand for energy and the need for skilled operators to manage complex plant processes are driving this growth.

What is the average salary for a Plant Operator Control Room Operator?

The average salary for a Plant Operator Control Room Operator varies depending on experience, location, and industry. According to Salary.com, the average salary for a Plant Operator Control Room Operator in the United States is around $75,000 per year.

What are the benefits of working as a Plant Operator Control Room Operator?

Benefits of working as a Plant Operator Control Room Operator include a competitive salary, good benefits, and the opportunity to work in a challenging and rewarding field.

What are the challenges of working as a Plant Operator Control Room Operator?

Challenges of working as a Plant Operator Control Room Operator include working long hours, including nights, weekends, and holidays, and working in a potentially hazardous environment.