Are you a seasoned Communications and Instrumentation Mechanic (C&I Mechanic) seeking a new career path? Discover our professionally built Communications and Instrumentation Mechanic (C&I Mechanic) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

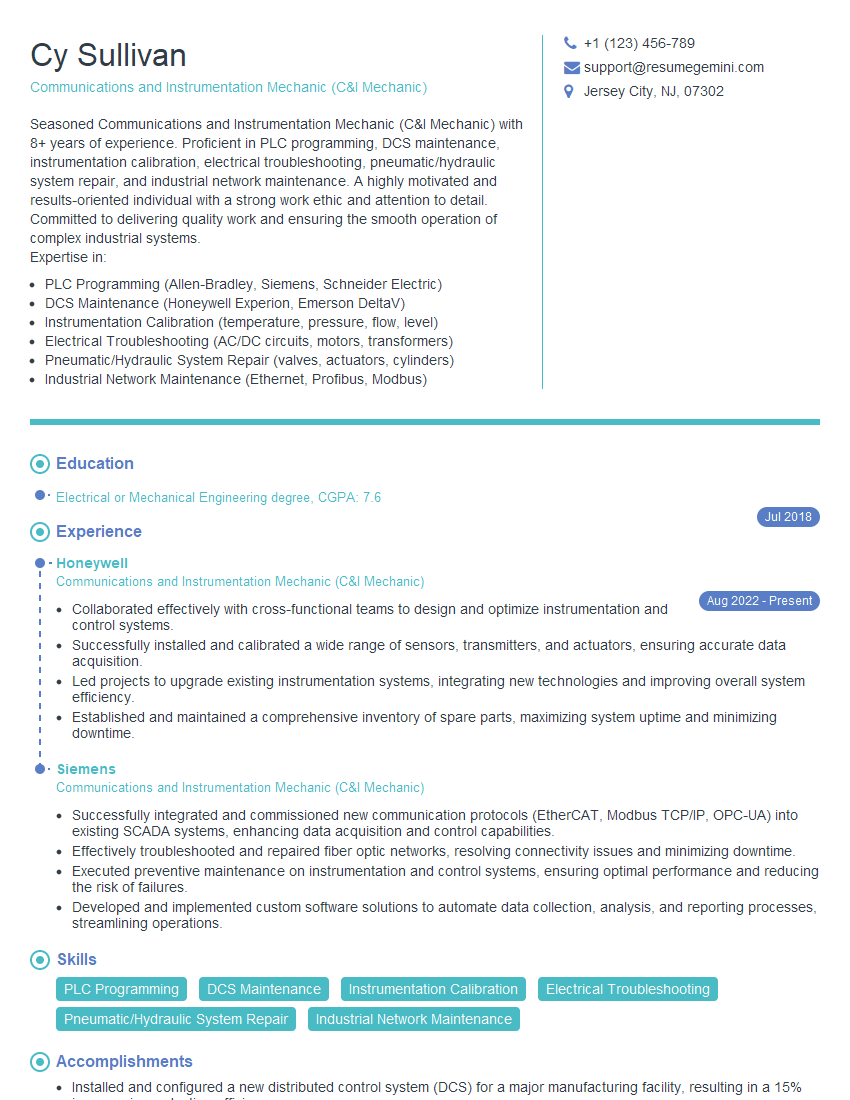

Cy Sullivan

Communications and Instrumentation Mechanic (C&I Mechanic)

Summary

Seasoned Communications and Instrumentation Mechanic (C&I Mechanic) with 8+ years of experience. Proficient in PLC programming, DCS maintenance, instrumentation calibration, electrical troubleshooting, pneumatic/hydraulic system repair, and industrial network maintenance. A highly motivated and results-oriented individual with a strong work ethic and attention to detail. Committed to delivering quality work and ensuring the smooth operation of complex industrial systems.

Expertise in:

- PLC Programming (Allen-Bradley, Siemens, Schneider Electric)

- DCS Maintenance (Honeywell Experion, Emerson DeltaV)

- Instrumentation Calibration (temperature, pressure, flow, level)

- Electrical Troubleshooting (AC/DC circuits, motors, transformers)

- Pneumatic/Hydraulic System Repair (valves, actuators, cylinders)

- Industrial Network Maintenance (Ethernet, Profibus, Modbus)

Education

Electrical or Mechanical Engineering degree

July 2018

Skills

- PLC Programming

- DCS Maintenance

- Instrumentation Calibration

- Electrical Troubleshooting

- Pneumatic/Hydraulic System Repair

- Industrial Network Maintenance

Work Experience

Communications and Instrumentation Mechanic (C&I Mechanic)

- Collaborated effectively with cross-functional teams to design and optimize instrumentation and control systems.

- Successfully installed and calibrated a wide range of sensors, transmitters, and actuators, ensuring accurate data acquisition.

- Led projects to upgrade existing instrumentation systems, integrating new technologies and improving overall system efficiency.

- Established and maintained a comprehensive inventory of spare parts, maximizing system uptime and minimizing downtime.

Communications and Instrumentation Mechanic (C&I Mechanic)

- Successfully integrated and commissioned new communication protocols (EtherCAT, Modbus TCP/IP, OPC-UA) into existing SCADA systems, enhancing data acquisition and control capabilities.

- Effectively troubleshooted and repaired fiber optic networks, resolving connectivity issues and minimizing downtime.

- Executed preventive maintenance on instrumentation and control systems, ensuring optimal performance and reducing the risk of failures.

- Developed and implemented custom software solutions to automate data collection, analysis, and reporting processes, streamlining operations.

Accomplishments

- Installed and configured a new distributed control system (DCS) for a major manufacturing facility, resulting in a 15% increase in production efficiency.

- Developed and implemented a preventative maintenance program for all plant instrumentation, reducing downtime by 20%.

- Troubleshooted and repaired a critical communication network outage, restoring plant operations within 2 hours.

- Upgraded and calibrated a variety of sensors and transmitters to meet industry standards, ensuring accurate and reliable data.

- Led a team of technicians in the installation and commissioning of a new SCADA system, improving plant visibility and control.

Awards

- Recipient of the Plant Excellence Award for outstanding contributions to the improvement of instrumentation and control systems.

- Recognized for exceptional troubleshooting skills and ability to resolve critical instrumentation issues.

- Awarded the Safety Excellence Award for consistently adhering to safety protocols and promoting a safe work environment.

Certificates

- ISA Certified Automation Professional (CAP)

- Siemens PLC Programming Certification

- Rockwell Automation ControlLogix Certification

- Yokogawa Centum VP Training Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Communications and Instrumentation Mechanic (C&I Mechanic)

- Demonstrate your expertise in your resume by highlighting specific projects and accomplishments where you applied your skills effectively.

- Quantify your achievements whenever possible to showcase the impact of your work.

- Tailor your resume to the specific job you are applying for, highlighting skills and experience that are relevant to the role.

- Proofread your resume carefully before submitting it, ensuring there are no errors in grammar, spelling, or formatting.

- Consider including a cover letter that briefly introduces yourself, highlights your key qualifications, and expresses your interest in the position.

Essential Experience Highlights for a Strong Communications and Instrumentation Mechanic (C&I Mechanic) Resume

- Installed, maintained, and repaired various types of instrumentation and control devices, including PLCs, DCSs, sensors, and actuators.

- Troubleshooted and resolved electrical, pneumatic, and hydraulic system malfunctions.

- Calibrated and tested instrumentation devices to ensure accuracy and reliability.

- Performed preventative maintenance and inspections to identify potential issues and prevent breakdowns.

- Worked effectively as part of a team and independently to complete projects on time and within budget.

- Stayed up-to-date on industry best practices and technological advancements.

- Provided technical support and training to other technicians and operators.

Frequently Asked Questions (FAQ’s) For Communications and Instrumentation Mechanic (C&I Mechanic)

What is the primary role of a Communications and Instrumentation Mechanic (C&I Mechanic)?

C&I Mechanics are responsible for the installation, maintenance, and repair of instrumentation and control systems used in various industries, such as manufacturing, power generation, and oil and gas.

What are the essential skills required to be a successful C&I Mechanic?

Strong understanding of electrical, pneumatic, and hydraulic systems, proficiency in PLC programming and DCS maintenance, and experience with instrumentation calibration are key skills for C&I Mechanics.

What industries employ C&I Mechanics?

C&I Mechanics are in demand in industries that rely on automated systems, including manufacturing, power generation, pharmaceuticals, and oil and gas.

What is the career outlook for C&I Mechanics?

The job outlook for C&I Mechanics is expected to be favorable in the coming years due to the increasing adoption of automation and the need for skilled technicians to maintain and repair these systems.

Can C&I Mechanics work independently?

While C&I Mechanics often work as part of a team, they may also be required to work independently to diagnose and resolve issues with instrumentation and control systems.

What are the common challenges faced by C&I Mechanics?

Troubleshooting complex systems, working in hazardous environments, and staying up-to-date with technological advancements are some of the challenges faced by C&I Mechanics.

What is the average salary for a C&I Mechanic?

The salary of a C&I Mechanic can vary based on experience, location, and industry, but on average, C&I Mechanics earn a competitive salary.

What are the advancement opportunities for C&I Mechanics?

With experience and additional training, C&I Mechanics can advance to roles such as Lead Technician, Maintenance Supervisor, or Engineering Technician.