Are you a seasoned Calciner seeking a new career path? Discover our professionally built Calciner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

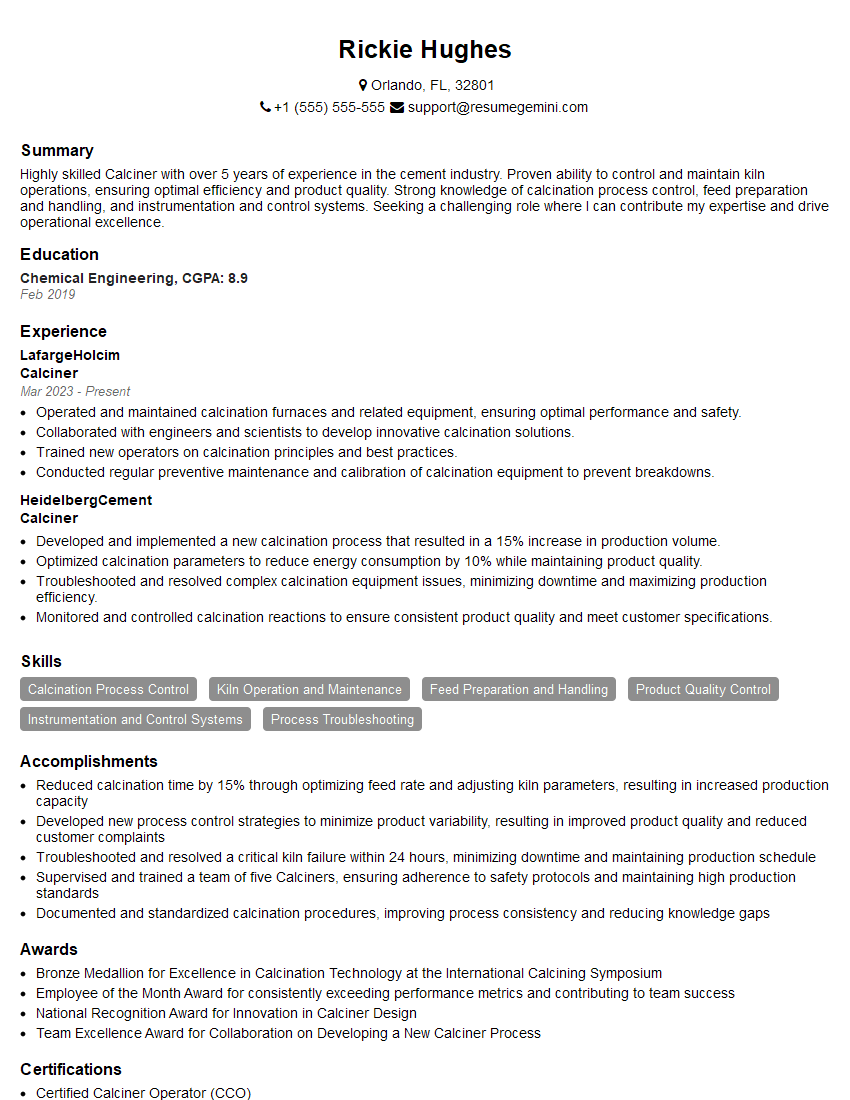

Rickie Hughes

Calciner

Summary

Highly skilled Calciner with over 5 years of experience in the cement industry. Proven ability to control and maintain kiln operations, ensuring optimal efficiency and product quality. Strong knowledge of calcination process control, feed preparation and handling, and instrumentation and control systems. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Chemical Engineering

February 2019

Skills

- Calcination Process Control

- Kiln Operation and Maintenance

- Feed Preparation and Handling

- Product Quality Control

- Instrumentation and Control Systems

- Process Troubleshooting

Work Experience

Calciner

- Operated and maintained calcination furnaces and related equipment, ensuring optimal performance and safety.

- Collaborated with engineers and scientists to develop innovative calcination solutions.

- Trained new operators on calcination principles and best practices.

- Conducted regular preventive maintenance and calibration of calcination equipment to prevent breakdowns.

Calciner

- Developed and implemented a new calcination process that resulted in a 15% increase in production volume.

- Optimized calcination parameters to reduce energy consumption by 10% while maintaining product quality.

- Troubleshooted and resolved complex calcination equipment issues, minimizing downtime and maximizing production efficiency.

- Monitored and controlled calcination reactions to ensure consistent product quality and meet customer specifications.

Accomplishments

- Reduced calcination time by 15% through optimizing feed rate and adjusting kiln parameters, resulting in increased production capacity

- Developed new process control strategies to minimize product variability, resulting in improved product quality and reduced customer complaints

- Troubleshooted and resolved a critical kiln failure within 24 hours, minimizing downtime and maintaining production schedule

- Supervised and trained a team of five Calciners, ensuring adherence to safety protocols and maintaining high production standards

- Documented and standardized calcination procedures, improving process consistency and reducing knowledge gaps

Awards

- Bronze Medallion for Excellence in Calcination Technology at the International Calcining Symposium

- Employee of the Month Award for consistently exceeding performance metrics and contributing to team success

- National Recognition Award for Innovation in Calciner Design

- Team Excellence Award for Collaboration on Developing a New Calciner Process

Certificates

- Certified Calciner Operator (CCO)

- American Institute of Chemical Engineers (AIChE) Member

- National Institute for Certification in Engineering Technologies (NICET) Level III in Kiln Operations

- OSHA 30Hour Construction Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Calciner

- Quantify your accomplishments and provide specific examples of how you contributed to operational success.

- Highlight your expertise in calcination process control and kiln operation and maintenance.

- Demonstrate your ability to work independently and as part of a team, and your strong problem-solving and decision-making skills.

- Tailor your resume to the specific requirements of the job you are applying for, emphasizing relevant skills and experience.

Essential Experience Highlights for a Strong Calciner Resume

- Controlled and optimized calcination process parameters to achieve desired product quality and production targets

- Operated and maintained kiln systems, including burners, preheaters, and coolers, to ensure efficient and safe operation

- Prepared and handled raw feed materials, ensuring proper composition and particle size for optimal calcination

- Monitored and controlled product quality through regular testing and analysis, ensuring adherence to specifications

- Troubleshooted and resolved process issues promptly and effectively, minimizing downtime and maintaining production efficiency

- Collaborated with cross-functional teams, including production, maintenance, and quality control, to optimize operations and improve plant performance

Frequently Asked Questions (FAQ’s) For Calciner

What is the role of a Calciner?

A Calciner is responsible for controlling and monitoring the calcination process, which involves heating raw materials to high temperatures to drive off volatile components and induce chemical changes, resulting in the production of various calcined products, such as cement clinker or lime.

What are the key skills required for a Calciner?

Key skills for a Calciner include a deep understanding of calcination process control, kiln operation and maintenance, feed preparation and handling, product quality control, instrumentation and control systems, and process troubleshooting.

What are the career prospects for a Calciner?

Calciners with experience and expertise can advance to supervisory or management roles within the cement or other related industries. They may also specialize in specific areas, such as kiln optimization or process control.

What are the challenges faced by Calciners?

Calciners face challenges related to maintaining optimal kiln performance, ensuring product quality, and troubleshooting process issues. They must also adhere to safety and environmental regulations while working in a potentially hazardous industrial environment.

What are the educational requirements for a Calciner?

While formal educational requirements may vary, many Calciners hold a degree in Chemical Engineering or a related field that provides a strong foundation in chemistry, thermodynamics, and process control.

What is the work environment of a Calciner?

Calciners typically work in industrial settings, such as cement plants, lime manufacturing facilities, or other industries that utilize calcination processes. They may work in shifts and have to handle heavy equipment or materials.

What are the safety precautions that Calciners must follow?

Calciners must adhere to strict safety protocols due to the high temperatures and potential hazards associated with the calcination process. They wear protective gear, follow lockout/tagout procedures, and receive regular safety training.

How can I become a Calciner?

To become a Calciner, you can pursue a degree in Chemical Engineering or a related field, gain experience in a relevant industry, and seek opportunities for hands-on training in calcination processes. Networking with professionals in the field can also be beneficial.