Are you a seasoned Buffing and Sueding Machine Operator seeking a new career path? Discover our professionally built Buffing and Sueding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

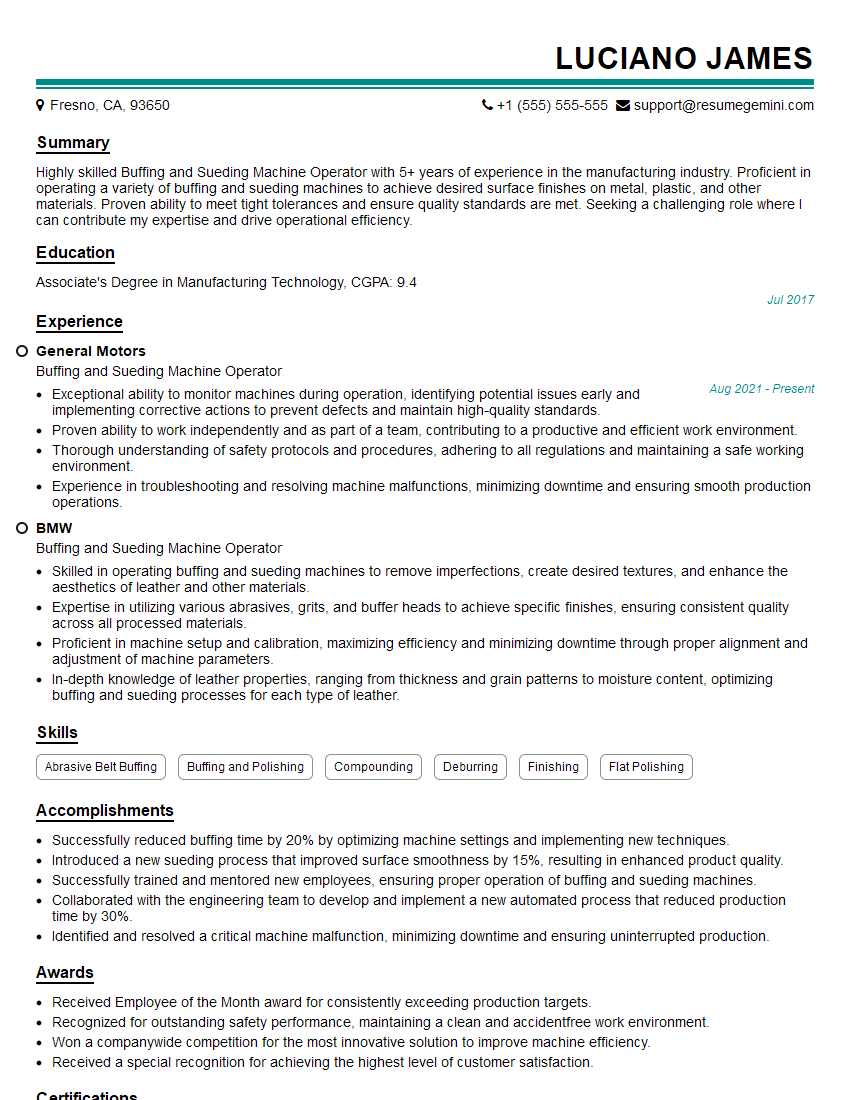

Luciano James

Buffing and Sueding Machine Operator

Summary

Highly skilled Buffing and Sueding Machine Operator with 5+ years of experience in the manufacturing industry. Proficient in operating a variety of buffing and sueding machines to achieve desired surface finishes on metal, plastic, and other materials. Proven ability to meet tight tolerances and ensure quality standards are met. Seeking a challenging role where I can contribute my expertise and drive operational efficiency.

Education

Associate’s Degree in Manufacturing Technology

July 2017

Skills

- Abrasive Belt Buffing

- Buffing and Polishing

- Compounding

- Deburring

- Finishing

- Flat Polishing

Work Experience

Buffing and Sueding Machine Operator

- Exceptional ability to monitor machines during operation, identifying potential issues early and implementing corrective actions to prevent defects and maintain high-quality standards.

- Proven ability to work independently and as part of a team, contributing to a productive and efficient work environment.

- Thorough understanding of safety protocols and procedures, adhering to all regulations and maintaining a safe working environment.

- Experience in troubleshooting and resolving machine malfunctions, minimizing downtime and ensuring smooth production operations.

Buffing and Sueding Machine Operator

- Skilled in operating buffing and sueding machines to remove imperfections, create desired textures, and enhance the aesthetics of leather and other materials.

- Expertise in utilizing various abrasives, grits, and buffer heads to achieve specific finishes, ensuring consistent quality across all processed materials.

- Proficient in machine setup and calibration, maximizing efficiency and minimizing downtime through proper alignment and adjustment of machine parameters.

- In-depth knowledge of leather properties, ranging from thickness and grain patterns to moisture content, optimizing buffing and sueding processes for each type of leather.

Accomplishments

- Successfully reduced buffing time by 20% by optimizing machine settings and implementing new techniques.

- Introduced a new sueding process that improved surface smoothness by 15%, resulting in enhanced product quality.

- Successfully trained and mentored new employees, ensuring proper operation of buffing and sueding machines.

- Collaborated with the engineering team to develop and implement a new automated process that reduced production time by 30%.

- Identified and resolved a critical machine malfunction, minimizing downtime and ensuring uninterrupted production.

Awards

- Received Employee of the Month award for consistently exceeding production targets.

- Recognized for outstanding safety performance, maintaining a clean and accidentfree work environment.

- Won a companywide competition for the most innovative solution to improve machine efficiency.

- Received a special recognition for achieving the highest level of customer satisfaction.

Certificates

- Buffing and Sueding Machine Operator Certification

- Polishing and Finishing Certification

- ISO 90012015 Quality Management Systems

- ASME B46.1 Surface Texture Standards

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Buffing and Sueding Machine Operator

- Highlight your experience and skills in operating different types of buffing and sueding machines.

- Quantify your accomplishments by providing specific examples of how you improved efficiency or reduced production costs.

- Emphasize your attention to detail, quality control, and ability to meet tight tolerances.

- Showcase your knowledge of industry best practices and safety regulations related to buffing and sueding operations.

Essential Experience Highlights for a Strong Buffing and Sueding Machine Operator Resume

- Operate and maintain buffing and sueding machines, ensuring proper setup and calibration.

- Select and install appropriate abrasives and compounds for specific material types and surface finishes.

- Monitor and adjust machine settings to achieve desired surface roughness, reflectivity, and texture.

- Inspect finished parts to ensure they meet quality standards and customer specifications.

- Maintain a clean and organized work area, following safety protocols and adhering to company policies.

- Troubleshoot and resolve machine malfunctions and breakdowns, minimizing downtime.

- Train and supervise junior operators, providing guidance and support.

Frequently Asked Questions (FAQ’s) For Buffing and Sueding Machine Operator

What are the primary responsibilities of a Buffing and Sueding Machine Operator?

Buffing and Sueding Machine Operators are responsible for operating and maintaining buffing and sueding machines to create desired surface finishes on various materials. They select and install appropriate abrasives and compounds, monitor machine settings, inspect finished parts, maintain a clean work area, and troubleshoot machine malfunctions.

What skills are required to be a successful Buffing and Sueding Machine Operator?

Successful Buffing and Sueding Machine Operators possess strong mechanical aptitude, attention to detail, and a commitment to quality control. They are proficient in operating different types of buffing and sueding machines, selecting appropriate abrasives and compounds, and troubleshooting machine malfunctions.

What industries employ Buffing and Sueding Machine Operators?

Buffing and Sueding Machine Operators are employed in a variety of industries, including automotive, aerospace, manufacturing, and metalworking. They work in factories, production facilities, and workshops, operating machines that create surface finishes on metal, plastic, and other materials.

How can I improve my chances of getting hired as a Buffing and Sueding Machine Operator?

To improve your chances of getting hired, highlight your experience and skills in operating buffing and sueding machines. Quantify your accomplishments, emphasize your attention to detail, and showcase your knowledge of industry best practices. Additionally, obtain relevant certifications and training to demonstrate your commitment to professional development.

What is the career outlook for Buffing and Sueding Machine Operators?

The career outlook for Buffing and Sueding Machine Operators is expected to be favorable in the coming years. The demand for skilled manufacturing professionals, including those who specialize in surface finishing, is increasing as industries continue to automate and optimize their production processes.

What are the advancement opportunities for Buffing and Sueding Machine Operators?

Buffing and Sueding Machine Operators can advance their careers by gaining experience and developing their skills. They may become supervisors, quality control inspectors, or production managers. With additional training and education, they may also move into engineering or management roles.