Are you a seasoned Carbon Plant Grinder seeking a new career path? Discover our professionally built Carbon Plant Grinder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

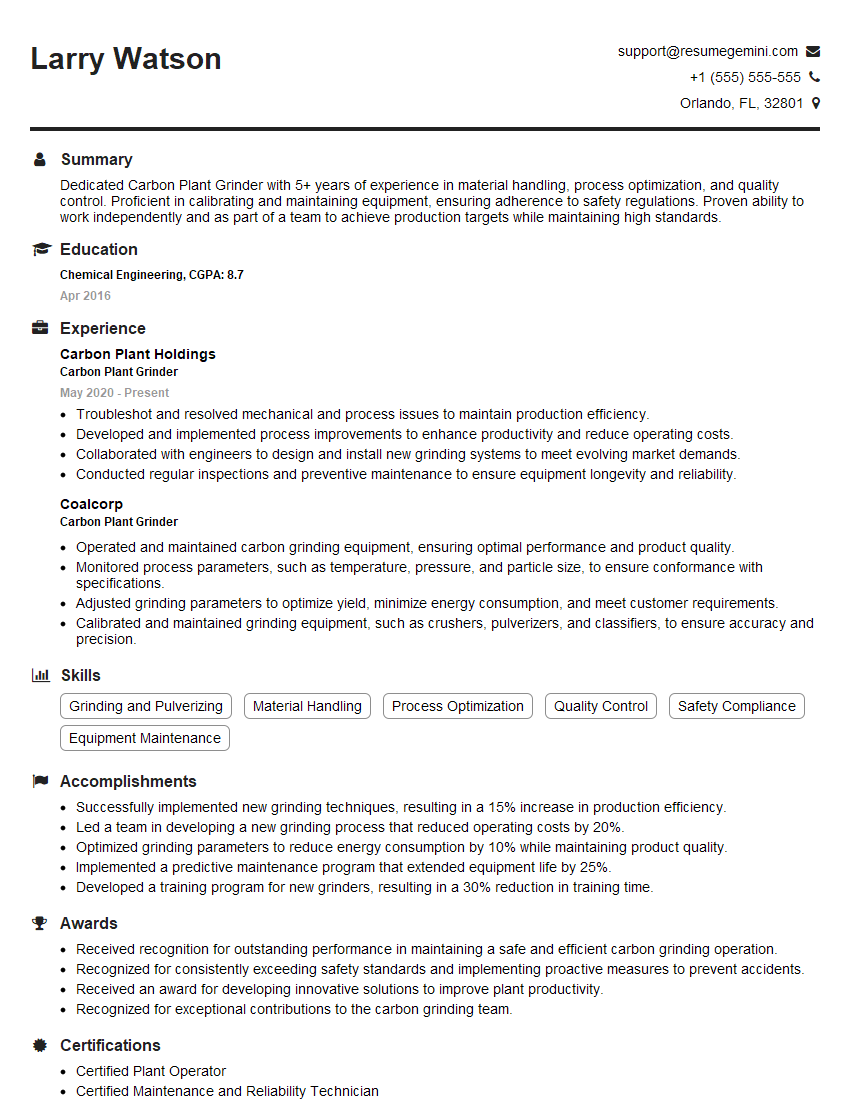

Larry Watson

Carbon Plant Grinder

Summary

Dedicated Carbon Plant Grinder with 5+ years of experience in material handling, process optimization, and quality control. Proficient in calibrating and maintaining equipment, ensuring adherence to safety regulations. Proven ability to work independently and as part of a team to achieve production targets while maintaining high standards.

Education

Chemical Engineering

April 2016

Skills

- Grinding and Pulverizing

- Material Handling

- Process Optimization

- Quality Control

- Safety Compliance

- Equipment Maintenance

Work Experience

Carbon Plant Grinder

- Troubleshot and resolved mechanical and process issues to maintain production efficiency.

- Developed and implemented process improvements to enhance productivity and reduce operating costs.

- Collaborated with engineers to design and install new grinding systems to meet evolving market demands.

- Conducted regular inspections and preventive maintenance to ensure equipment longevity and reliability.

Carbon Plant Grinder

- Operated and maintained carbon grinding equipment, ensuring optimal performance and product quality.

- Monitored process parameters, such as temperature, pressure, and particle size, to ensure conformance with specifications.

- Adjusted grinding parameters to optimize yield, minimize energy consumption, and meet customer requirements.

- Calibrated and maintained grinding equipment, such as crushers, pulverizers, and classifiers, to ensure accuracy and precision.

Accomplishments

- Successfully implemented new grinding techniques, resulting in a 15% increase in production efficiency.

- Led a team in developing a new grinding process that reduced operating costs by 20%.

- Optimized grinding parameters to reduce energy consumption by 10% while maintaining product quality.

- Implemented a predictive maintenance program that extended equipment life by 25%.

- Developed a training program for new grinders, resulting in a 30% reduction in training time.

Awards

- Received recognition for outstanding performance in maintaining a safe and efficient carbon grinding operation.

- Recognized for consistently exceeding safety standards and implementing proactive measures to prevent accidents.

- Received an award for developing innovative solutions to improve plant productivity.

- Recognized for exceptional contributions to the carbon grinding team.

Certificates

- Certified Plant Operator

- Certified Maintenance and Reliability Technician

- Certified Electrical System Troubleshooter

- Certified Safety Compliance Officer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carbon Plant Grinder

- Highlight your technical expertise in grinding and pulverizing operations.

- Quantify your achievements in optimizing process efficiency and improving product quality.

- Demonstrate your commitment to safety and compliance by providing specific examples.

- Showcase your problem-solving skills and ability to work effectively in both individual and team settings.

Essential Experience Highlights for a Strong Carbon Plant Grinder Resume

- Grind and pulverize carbon feedstock to meet specified particle size requirements

- Operate and maintain grinding and pulverizing equipment, including ball mills and crushers

- Monitor and adjust process parameters to optimize grinding efficiency and product quality

- Conduct quality control tests on ground material to ensure adherence to specifications

- Maintain a safe and clean work environment, adhering to established safety protocols

- Troubleshoot and resolve equipment malfunctions, ensuring minimal downtime

Frequently Asked Questions (FAQ’s) For Carbon Plant Grinder

What does a Carbon Plant Grinder do?

A Carbon Plant Grinder operates and maintains equipment used to grind and pulverize carbon feedstock, ensuring adherence to specified particle size requirements and product quality.

What qualifications are required to become a Carbon Plant Grinder?

Typically, a degree in Chemical Engineering or a related field, coupled with experience in material handling, process optimization, and quality control is required.

What are the key responsibilities of a Carbon Plant Grinder?

Key responsibilities include operating and maintaining grinding equipment, monitoring process parameters, conducting quality control tests, troubleshooting malfunctions, and adhering to safety regulations.

What are the career prospects for a Carbon Plant Grinder?

With experience and additional training, Carbon Plant Grinders can advance to roles such as Process Engineer, Production Supervisor, or Plant Manager.

What is the work environment of a Carbon Plant Grinder like?

Carbon Plant Grinders typically work in industrial settings, operating and maintaining equipment in production facilities. They may work independently or as part of a team, and must be able to work in a fast-paced environment.

What are the challenges faced by a Carbon Plant Grinder?

Challenges may include working in a noisy and dusty environment, exposure to chemicals, and the need to troubleshoot and resolve equipment malfunctions promptly to minimize downtime.

What are the safety precautions that a Carbon Plant Grinder must observe?

Carbon Plant Grinders must adhere to established safety protocols, wear appropriate protective gear, and be aware of potential hazards associated with operating heavy machinery and working with chemicals.