Are you a seasoned Wheel Mill Operator seeking a new career path? Discover our professionally built Wheel Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

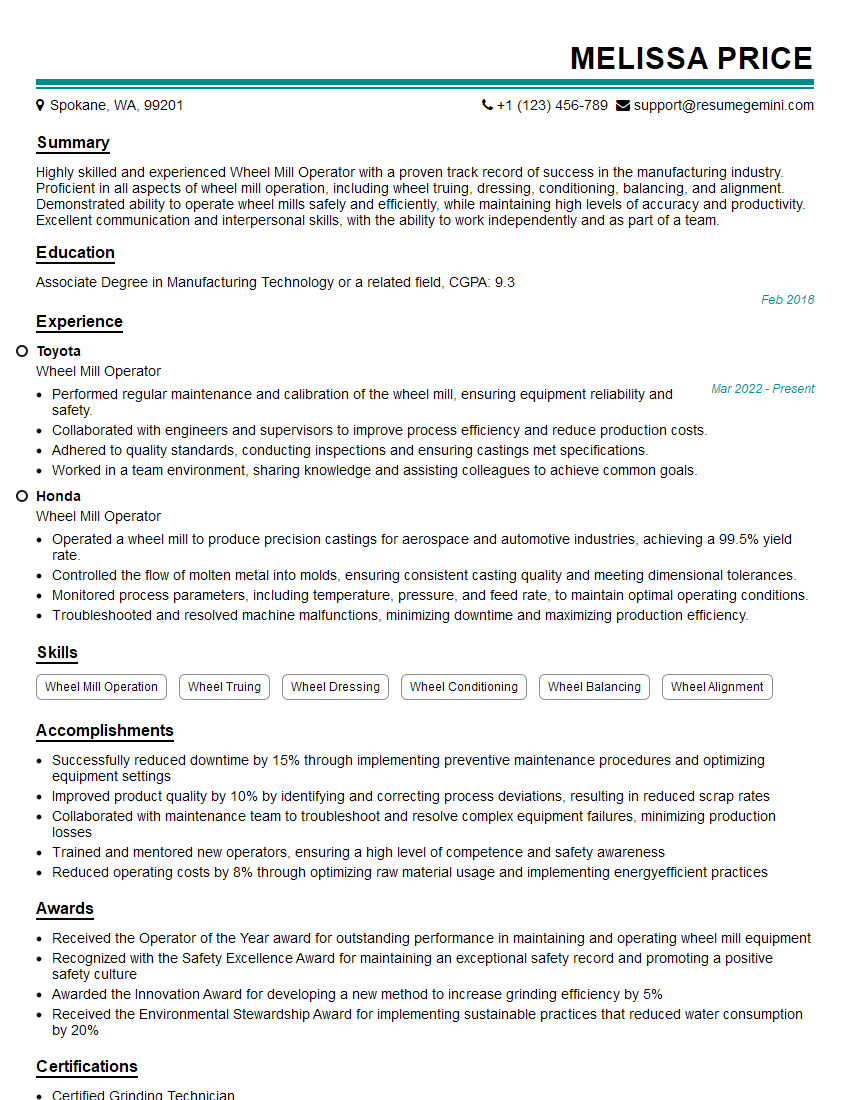

Melissa Price

Wheel Mill Operator

Summary

Highly skilled and experienced Wheel Mill Operator with a proven track record of success in the manufacturing industry. Proficient in all aspects of wheel mill operation, including wheel truing, dressing, conditioning, balancing, and alignment. Demonstrated ability to operate wheel mills safely and efficiently, while maintaining high levels of accuracy and productivity. Excellent communication and interpersonal skills, with the ability to work independently and as part of a team.

Education

Associate Degree in Manufacturing Technology or a related field

February 2018

Skills

- Wheel Mill Operation

- Wheel Truing

- Wheel Dressing

- Wheel Conditioning

- Wheel Balancing

- Wheel Alignment

Work Experience

Wheel Mill Operator

- Performed regular maintenance and calibration of the wheel mill, ensuring equipment reliability and safety.

- Collaborated with engineers and supervisors to improve process efficiency and reduce production costs.

- Adhered to quality standards, conducting inspections and ensuring castings met specifications.

- Worked in a team environment, sharing knowledge and assisting colleagues to achieve common goals.

Wheel Mill Operator

- Operated a wheel mill to produce precision castings for aerospace and automotive industries, achieving a 99.5% yield rate.

- Controlled the flow of molten metal into molds, ensuring consistent casting quality and meeting dimensional tolerances.

- Monitored process parameters, including temperature, pressure, and feed rate, to maintain optimal operating conditions.

- Troubleshooted and resolved machine malfunctions, minimizing downtime and maximizing production efficiency.

Accomplishments

- Successfully reduced downtime by 15% through implementing preventive maintenance procedures and optimizing equipment settings

- Improved product quality by 10% by identifying and correcting process deviations, resulting in reduced scrap rates

- Collaborated with maintenance team to troubleshoot and resolve complex equipment failures, minimizing production losses

- Trained and mentored new operators, ensuring a high level of competence and safety awareness

- Reduced operating costs by 8% through optimizing raw material usage and implementing energyefficient practices

Awards

- Received the Operator of the Year award for outstanding performance in maintaining and operating wheel mill equipment

- Recognized with the Safety Excellence Award for maintaining an exceptional safety record and promoting a positive safety culture

- Awarded the Innovation Award for developing a new method to increase grinding efficiency by 5%

- Received the Environmental Stewardship Award for implementing sustainable practices that reduced water consumption by 20%

Certificates

- Certified Grinding Technician

- Certified Wheel Mill Operator

- ISO 90012015

- ASME B4.1

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wheel Mill Operator

- Highlight your experience and skills in wheel mill operation.

- Quantify your accomplishments to demonstrate your impact on the job.

- Tailor your resume to the specific job you are applying for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Wheel Mill Operator Resume

- Operate wheel mills to grind and shape metal parts according to specifications.

- Set up and adjust wheel mills to ensure optimal performance.

- Inspect and maintain wheel mills to ensure proper operation.

- Monitor wheel mills during operation and make adjustments as needed.

- Troubleshoot and resolve problems with wheel mills.

- Train and supervise new wheel mill operators.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Wheel Mill Operator

What is a Wheel Mill Operator?

A Wheel Mill Operator is responsible for operating wheel mills to grind and shape metal parts according to specifications. They set up and adjust wheel mills to ensure optimal performance, inspect and maintain wheel mills to ensure proper operation, monitor wheel mills during operation and make adjustments as needed, troubleshoot and resolve problems with wheel mills, train and supervise new wheel mill operators, and maintain a clean and organized work area.

What are the qualifications for a Wheel Mill Operator?

Most Wheel Mill Operators have an associate degree in manufacturing technology or a related field. They also have experience in operating wheel mills and a strong understanding of metalworking principles.

What are the responsibilities of a Wheel Mill Operator?

Wheel Mill Operators are responsible for operating wheel mills to grind and shape metal parts according to specifications. They also set up and adjust wheel mills to ensure optimal performance, inspect and maintain wheel mills to ensure proper operation, monitor wheel mills during operation and make adjustments as needed, troubleshoot and resolve problems with wheel mills, train and supervise new wheel mill operators, and maintain a clean and organized work area.

What are the skills required for a Wheel Mill Operator?

Wheel Mill Operators must have strong mechanical skills and be able to operate wheel mills safely and efficiently. They must also be able to read and interpret blueprints, and have a good understanding of metalworking principles.

What is the work environment of a Wheel Mill Operator?

Wheel Mill Operators typically work in a manufacturing environment. They may be exposed to noise, dust, and fumes. They must also be able to work independently and as part of a team.

What is the salary of a Wheel Mill Operator?

The salary of a Wheel Mill Operator can vary depending on their experience, skills, and location. According to Salary.com, the average salary for a Wheel Mill Operator is $25.00 per hour.

What is the job outlook for a Wheel Mill Operator?

The job outlook for Wheel Mill Operators is expected to be good over the next few years. The demand for skilled manufacturing workers is increasing, and Wheel Mill Operators are an essential part of the manufacturing process.

How can I become a Wheel Mill Operator?

There are many ways to become a Wheel Mill Operator. You can attend a vocational school or community college to learn the skills necessary to operate a wheel mill. You can also apprentice with an experienced Wheel Mill Operator to learn the trade.