Are you a seasoned Plastic Mixer seeking a new career path? Discover our professionally built Plastic Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

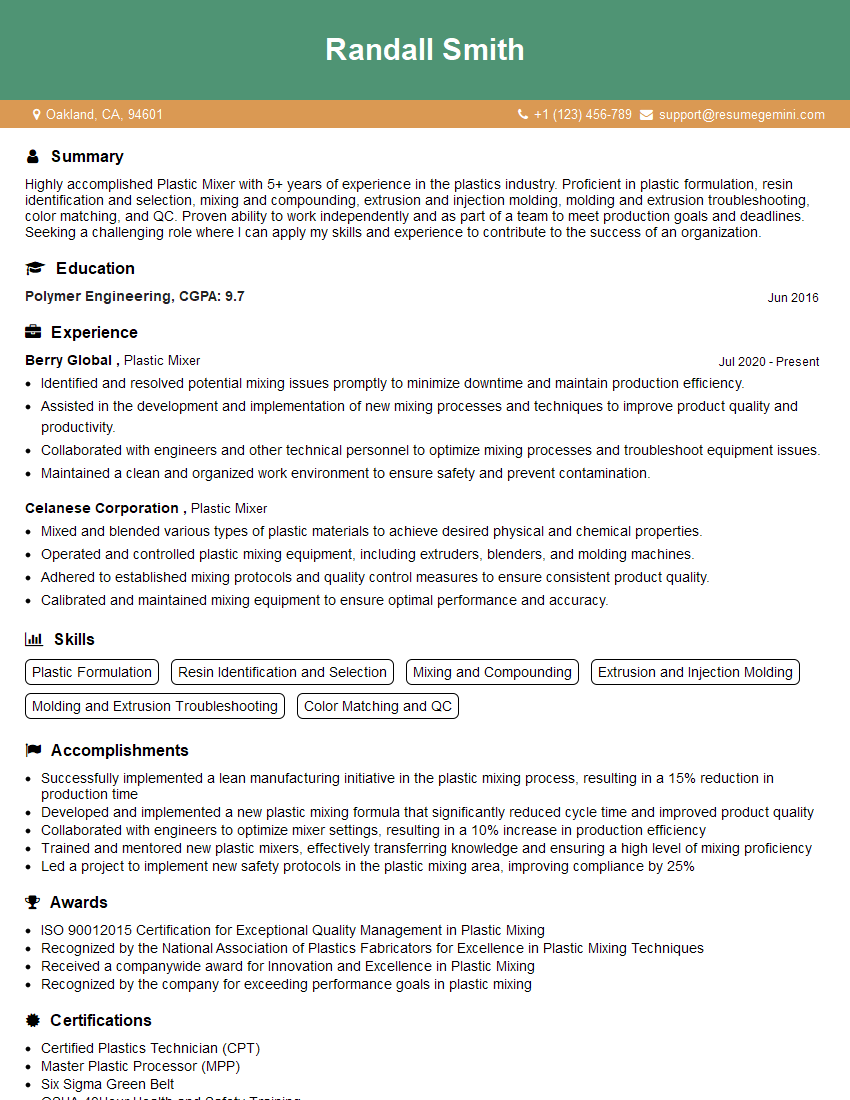

Randall Smith

Plastic Mixer

Summary

Highly accomplished Plastic Mixer with 5+ years of experience in the plastics industry. Proficient in plastic formulation, resin identification and selection, mixing and compounding, extrusion and injection molding, molding and extrusion troubleshooting, color matching, and QC. Proven ability to work independently and as part of a team to meet production goals and deadlines. Seeking a challenging role where I can apply my skills and experience to contribute to the success of an organization.

Education

Polymer Engineering

June 2016

Skills

- Plastic Formulation

- Resin Identification and Selection

- Mixing and Compounding

- Extrusion and Injection Molding

- Molding and Extrusion Troubleshooting

- Color Matching and QC

Work Experience

Plastic Mixer

- Identified and resolved potential mixing issues promptly to minimize downtime and maintain production efficiency.

- Assisted in the development and implementation of new mixing processes and techniques to improve product quality and productivity.

- Collaborated with engineers and other technical personnel to optimize mixing processes and troubleshoot equipment issues.

- Maintained a clean and organized work environment to ensure safety and prevent contamination.

Plastic Mixer

- Mixed and blended various types of plastic materials to achieve desired physical and chemical properties.

- Operated and controlled plastic mixing equipment, including extruders, blenders, and molding machines.

- Adhered to established mixing protocols and quality control measures to ensure consistent product quality.

- Calibrated and maintained mixing equipment to ensure optimal performance and accuracy.

Accomplishments

- Successfully implemented a lean manufacturing initiative in the plastic mixing process, resulting in a 15% reduction in production time

- Developed and implemented a new plastic mixing formula that significantly reduced cycle time and improved product quality

- Collaborated with engineers to optimize mixer settings, resulting in a 10% increase in production efficiency

- Trained and mentored new plastic mixers, effectively transferring knowledge and ensuring a high level of mixing proficiency

- Led a project to implement new safety protocols in the plastic mixing area, improving compliance by 25%

Awards

- ISO 90012015 Certification for Exceptional Quality Management in Plastic Mixing

- Recognized by the National Association of Plastics Fabricators for Excellence in Plastic Mixing Techniques

- Received a companywide award for Innovation and Excellence in Plastic Mixing

- Recognized by the company for exceeding performance goals in plastic mixing

Certificates

- Certified Plastics Technician (CPT)

- Master Plastic Processor (MPP)

- Six Sigma Green Belt

- OSHA 40Hour Health and Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Mixer

- Highlight your technical skills and experience in plastic formulation, mixing, and molding.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Plastic Mixer Resume

- Developed and optimized plastic formulations to meet specific product requirements.

- Identified and selected appropriate resins based on the desired properties and performance.

- Mixed and compounded plastic materials using a variety of equipment and techniques.

- Operated extrusion and injection molding machines to produce plastic products.

- Troubleshooted and resolved molding and extrusion issues to ensure efficient production.

- Matched colors to customer specifications and performed quality control inspections.

- Collaborated with engineers and other team members to develop and improve production processes.

Frequently Asked Questions (FAQ’s) For Plastic Mixer

What is the role of a Plastic Mixer?

A Plastic Mixer is responsible for mixing and compounding plastic materials to create products with specific properties and performance characteristics.

What skills are required to be a Plastic Mixer?

A Plastic Mixer should have a strong understanding of plastic formulation, resin identification and selection, mixing and compounding, extrusion and injection molding, molding and extrusion troubleshooting, color matching, and QC.

What is the career path for a Plastic Mixer?

Plastic Mixers can advance to positions such as Production Supervisor, Quality Control Manager, or Process Engineer.

What is the salary range for a Plastic Mixer?

The salary range for a Plastic Mixer can vary depending on experience, location, and company size, but typically falls between $40,000 and $70,000.

What are the job opportunities for a Plastic Mixer?

Plastic Mixers are employed in a variety of industries, including automotive, construction, electronics, and packaging.

What is the work environment for a Plastic Mixer?

Plastic Mixers typically work in a manufacturing environment, which can be noisy and dusty.

What are the benefits of being a Plastic Mixer?

Plastic Mixers can enjoy a stable career with good pay and benefits, as well as the opportunity to work with a variety of materials and processes.