Are you a seasoned Aluminum Sheet Cutter seeking a new career path? Discover our professionally built Aluminum Sheet Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

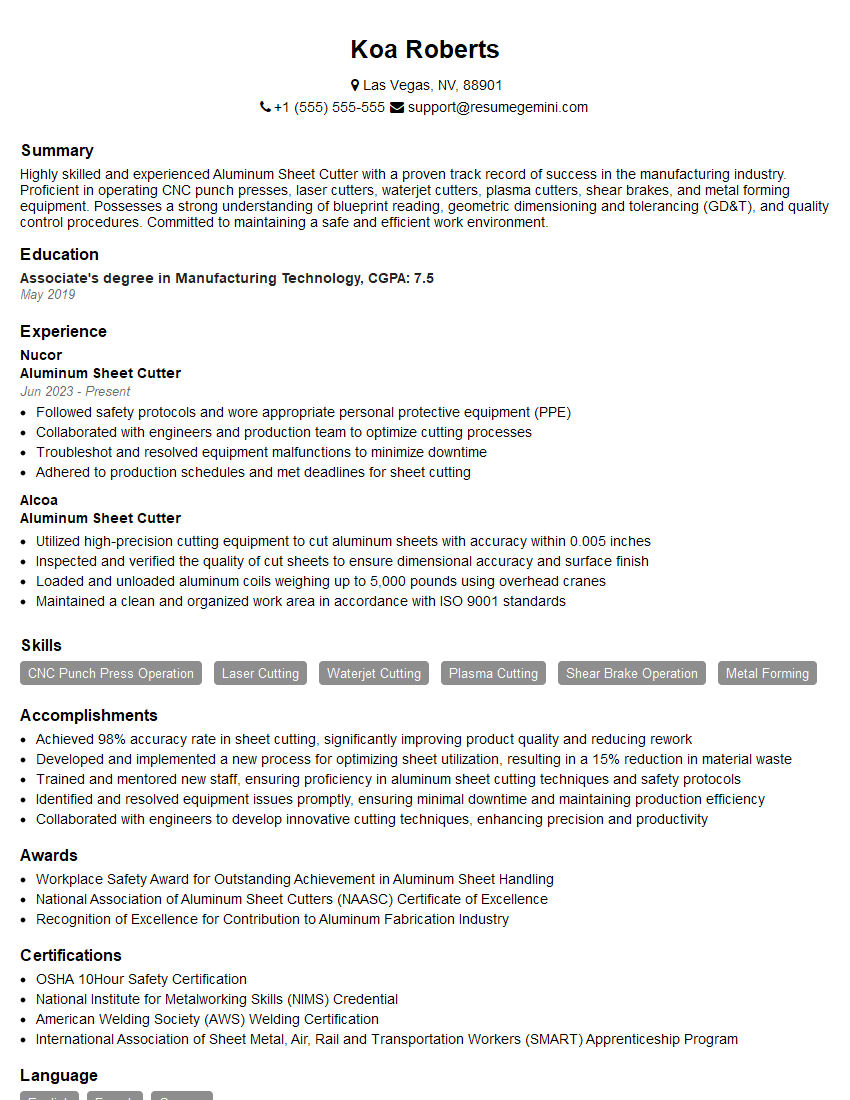

Koa Roberts

Aluminum Sheet Cutter

Summary

Highly skilled and experienced Aluminum Sheet Cutter with a proven track record of success in the manufacturing industry. Proficient in operating CNC punch presses, laser cutters, waterjet cutters, plasma cutters, shear brakes, and metal forming equipment. Possesses a strong understanding of blueprint reading, geometric dimensioning and tolerancing (GD&T), and quality control procedures. Committed to maintaining a safe and efficient work environment.

Education

Associate’s degree in Manufacturing Technology

May 2019

Skills

- CNC Punch Press Operation

- Laser Cutting

- Waterjet Cutting

- Plasma Cutting

- Shear Brake Operation

- Metal Forming

Work Experience

Aluminum Sheet Cutter

- Followed safety protocols and wore appropriate personal protective equipment (PPE)

- Collaborated with engineers and production team to optimize cutting processes

- Troubleshot and resolved equipment malfunctions to minimize downtime

- Adhered to production schedules and met deadlines for sheet cutting

Aluminum Sheet Cutter

- Utilized high-precision cutting equipment to cut aluminum sheets with accuracy within 0.005 inches

- Inspected and verified the quality of cut sheets to ensure dimensional accuracy and surface finish

- Loaded and unloaded aluminum coils weighing up to 5,000 pounds using overhead cranes

- Maintained a clean and organized work area in accordance with ISO 9001 standards

Accomplishments

- Achieved 98% accuracy rate in sheet cutting, significantly improving product quality and reducing rework

- Developed and implemented a new process for optimizing sheet utilization, resulting in a 15% reduction in material waste

- Trained and mentored new staff, ensuring proficiency in aluminum sheet cutting techniques and safety protocols

- Identified and resolved equipment issues promptly, ensuring minimal downtime and maintaining production efficiency

- Collaborated with engineers to develop innovative cutting techniques, enhancing precision and productivity

Awards

- Workplace Safety Award for Outstanding Achievement in Aluminum Sheet Handling

- National Association of Aluminum Sheet Cutters (NAASC) Certificate of Excellence

- Recognition of Excellence for Contribution to Aluminum Fabrication Industry

Certificates

- OSHA 10Hour Safety Certification

- National Institute for Metalworking Skills (NIMS) Credential

- American Welding Society (AWS) Welding Certification

- International Association of Sheet Metal, Air, Rail and Transportation Workers (SMART) Apprenticeship Program

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aluminum Sheet Cutter

- Highlight your experience and skills in operating CNC punch presses, laser cutters, and other cutting and forming equipment.

- Showcase your knowledge of blueprint reading, GD&T, and quality control procedures.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it to ensure it is error-free.

Essential Experience Highlights for a Strong Aluminum Sheet Cutter Resume

- Set up and operate CNC punch presses, laser cutters, waterjet cutters, plasma cutters, shear brakes, and metal forming equipment to cut and form aluminum sheets according to specifications.

- Interpret blueprints, drawings, and other technical documents to determine cutting and forming requirements.

- Measure and inspect finished parts to ensure they meet specifications and quality standards.

- Maintain and calibrate cutting and forming equipment to ensure optimal performance.

- Follow safety protocols and procedures to maintain a safe work environment.

- Troubleshoot and resolve problems with cutting and forming equipment and processes.

- Assist with the development and implementation of new cutting and forming techniques.

Frequently Asked Questions (FAQ’s) For Aluminum Sheet Cutter

What are the key skills required to be an Aluminum Sheet Cutter?

The key skills required to be an Aluminum Sheet Cutter include proficiency in operating CNC punch presses, laser cutters, waterjet cutters, plasma cutters, shear brakes, and metal forming equipment. Additionally, Aluminum Sheet Cutters must have a strong understanding of blueprint reading, GD&T, and quality control procedures.

What are the typical job duties of an Aluminum Sheet Cutter?

The typical job duties of an Aluminum Sheet Cutter include setting up and operating CNC punch presses, laser cutters, waterjet cutters, plasma cutters, shear brakes, and metal forming equipment to cut and form aluminum sheets according to specifications. They also interpret blueprints, drawings, and other technical documents to determine cutting and forming requirements, measure and inspect finished parts to ensure they meet specifications and quality standards, and maintain and calibrate cutting and forming equipment to ensure optimal performance.

What is the average salary for an Aluminum Sheet Cutter?

According to Salary.com, the average salary for an Aluminum Sheet Cutter in the United States is $49,000. However, salaries can vary depending on experience, location, and employer.

What are the career prospects for Aluminum Sheet Cutters?

Aluminum Sheet Cutters with experience and skills in operating CNC punch presses, laser cutters, and other cutting and forming equipment can advance to supervisory or management positions. They can also specialize in a particular type of cutting or forming, such as laser cutting or waterjet cutting.

What are the educational requirements for Aluminum Sheet Cutters?

Most Aluminum Sheet Cutters have an associate’s degree in Manufacturing Technology or a related field. However, some employers may hire candidates with a high school diploma or GED and relevant experience.

What are the safety protocols that Aluminum Sheet Cutters must follow?

Aluminum Sheet Cutters must follow all safety protocols and procedures established by their employer. These protocols may include wearing appropriate safety gear, such as gloves, safety glasses, and earplugs; using proper lifting techniques; and being aware of potential hazards in the work environment.

What are the key qualities of a successful Aluminum Sheet Cutter?

Successful Aluminum Sheet Cutters are typically detail-oriented, have strong hand-eye coordination, and are able to work independently and as part of a team. They are also able to follow instructions carefully and are committed to maintaining a safe and efficient work environment.

What are the top companies that hire Aluminum Sheet Cutters?

Some of the top companies that hire Aluminum Sheet Cutters include Nucor, Alcoa, and Arconic.