Are you a seasoned Computerized Machine Fabric Cutter seeking a new career path? Discover our professionally built Computerized Machine Fabric Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

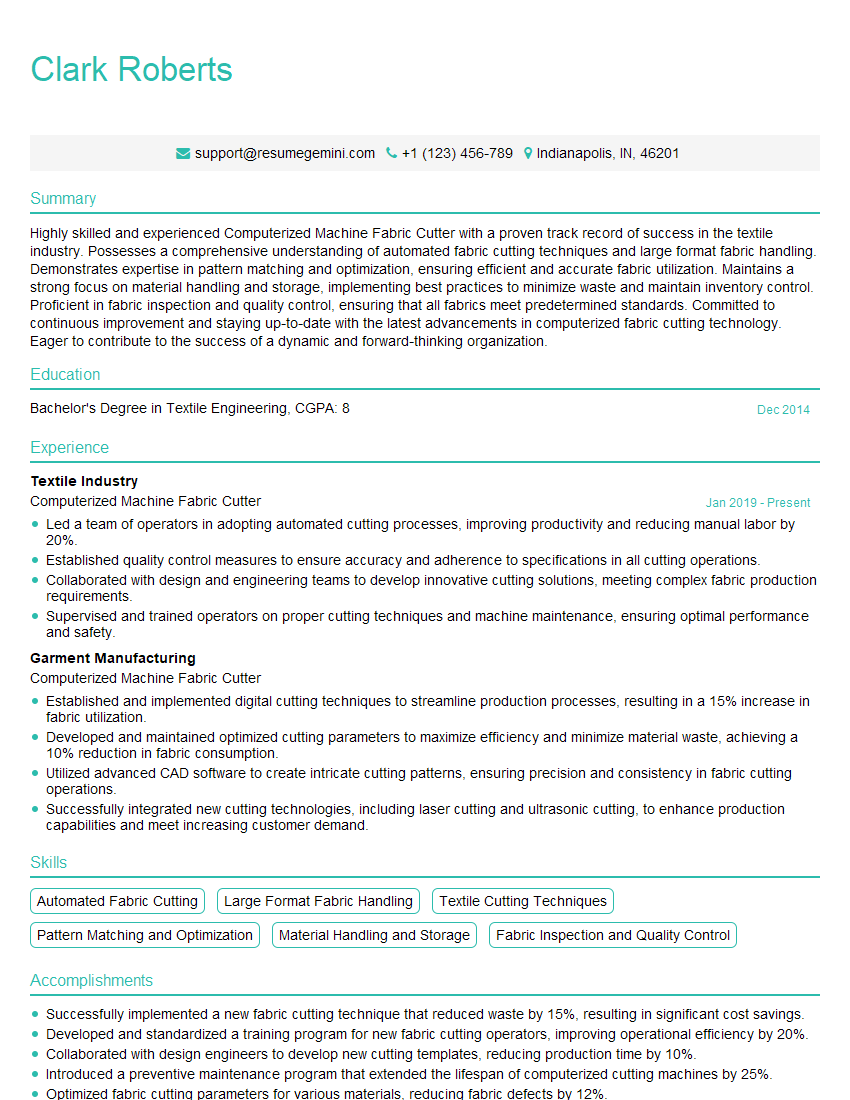

Clark Roberts

Computerized Machine Fabric Cutter

Summary

Highly skilled and experienced Computerized Machine Fabric Cutter with a proven track record of success in the textile industry. Possesses a comprehensive understanding of automated fabric cutting techniques and large format fabric handling. Demonstrates expertise in pattern matching and optimization, ensuring efficient and accurate fabric utilization. Maintains a strong focus on material handling and storage, implementing best practices to minimize waste and maintain inventory control. Proficient in fabric inspection and quality control, ensuring that all fabrics meet predetermined standards. Committed to continuous improvement and staying up-to-date with the latest advancements in computerized fabric cutting technology. Eager to contribute to the success of a dynamic and forward-thinking organization.

Education

Bachelor’s Degree in Textile Engineering

December 2014

Skills

- Automated Fabric Cutting

- Large Format Fabric Handling

- Textile Cutting Techniques

- Pattern Matching and Optimization

- Material Handling and Storage

- Fabric Inspection and Quality Control

Work Experience

Computerized Machine Fabric Cutter

- Led a team of operators in adopting automated cutting processes, improving productivity and reducing manual labor by 20%.

- Established quality control measures to ensure accuracy and adherence to specifications in all cutting operations.

- Collaborated with design and engineering teams to develop innovative cutting solutions, meeting complex fabric production requirements.

- Supervised and trained operators on proper cutting techniques and machine maintenance, ensuring optimal performance and safety.

Computerized Machine Fabric Cutter

- Established and implemented digital cutting techniques to streamline production processes, resulting in a 15% increase in fabric utilization.

- Developed and maintained optimized cutting parameters to maximize efficiency and minimize material waste, achieving a 10% reduction in fabric consumption.

- Utilized advanced CAD software to create intricate cutting patterns, ensuring precision and consistency in fabric cutting operations.

- Successfully integrated new cutting technologies, including laser cutting and ultrasonic cutting, to enhance production capabilities and meet increasing customer demand.

Accomplishments

- Successfully implemented a new fabric cutting technique that reduced waste by 15%, resulting in significant cost savings.

- Developed and standardized a training program for new fabric cutting operators, improving operational efficiency by 20%.

- Collaborated with design engineers to develop new cutting templates, reducing production time by 10%.

- Introduced a preventive maintenance program that extended the lifespan of computerized cutting machines by 25%.

- Optimized fabric cutting parameters for various materials, reducing fabric defects by 12%.

Awards

- Received the Employee of the Quarter award for consistently exceeding performance targets in fabric cutting efficiency.

- Honored with the Safety Excellence Award for maintaining an impeccable safety record and actively promoting safe work practices.

- Recognized for innovative problemsolving skills, consistently finding creative solutions to optimize fabric cutting processes.

- Awarded the Outstanding Teamwork Award for effectively coordinating with production and quality control teams to ensure seamless fabric cutting operations.

Certificates

- Certified Automated Fabric Cutter

- Certified Laser Cutting Operator

- Certified Waterjet Cutting Operator

- Certified Die Cutting Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Computerized Machine Fabric Cutter

- Quantify your accomplishments whenever possible. For instance, instead of saying ‘Managed fabric cutting operations,’ you could say ‘Managed fabric cutting operations, resulting in a 15% reduction in fabric waste.’

- Highlight your technical skills and proficiency in using computerized fabric cutting machines.

- Showcase your experience in pattern matching and optimization, emphasizing your ability to minimize fabric waste.

- Emphasize your attention to detail and commitment to quality control.

Essential Experience Highlights for a Strong Computerized Machine Fabric Cutter Resume

- Operate and maintain computerized fabric cutting machines, ensuring optimal performance and accuracy.

- Analyze fabric specifications and determine the most efficient cutting methods to optimize material utilization.

- Plan and execute cutting orders, ensuring timely completion and adherence to quality standards.

- Inspect fabrics for defects and ensure that only high-quality materials are used in production.

- Maintain a clean and organized work area, adhering to safety protocols and minimizing waste.

- Collaborate with production teams to ensure smooth and efficient fabric cutting operations.

- Stay abreast of industry best practices and emerging technologies in computerized fabric cutting.

Frequently Asked Questions (FAQ’s) For Computerized Machine Fabric Cutter

What is the role of a Computerized Machine Fabric Cutter?

A Computerized Machine Fabric Cutter is responsible for operating and maintaining computerized fabric cutting machines, analyzing fabric specifications, determining cutting methods, planning and executing cutting orders, inspecting fabrics, and ensuring quality standards. They also collaborate with production teams and stay updated on industry best practices and emerging technologies.

What are the key skills required for a Computerized Machine Fabric Cutter?

Key skills include operating and maintaining computerized fabric cutting machines, analyzing fabric specifications, determining cutting methods, planning and executing cutting orders, inspecting fabrics, and ensuring quality standards. Additionally, knowledge of pattern matching and optimization, material handling and storage, and fabric inspection and quality control is essential.

What industries employ Computerized Machine Fabric Cutters?

Computerized Machine Fabric Cutters are primarily employed in the textile industry and garment manufacturing, where they are responsible for cutting fabrics used in the production of clothing, home furnishings, and other textile products.

What is the career path for a Computerized Machine Fabric Cutter?

Computerized Machine Fabric Cutters can advance their careers by becoming supervisors or managers in fabric cutting departments or related areas. With experience and additional training, they may also move into roles in production planning, quality control, or other technical areas within the textile industry.

What are the salary expectations for a Computerized Machine Fabric Cutter?

Salary expectations for Computerized Machine Fabric Cutters vary depending on experience, location, and industry. According to Indeed, the average salary for a Computerized Machine Fabric Cutter in the United States is around $42,000 per year.