Are you a seasoned Dipping Machine Operator seeking a new career path? Discover our professionally built Dipping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

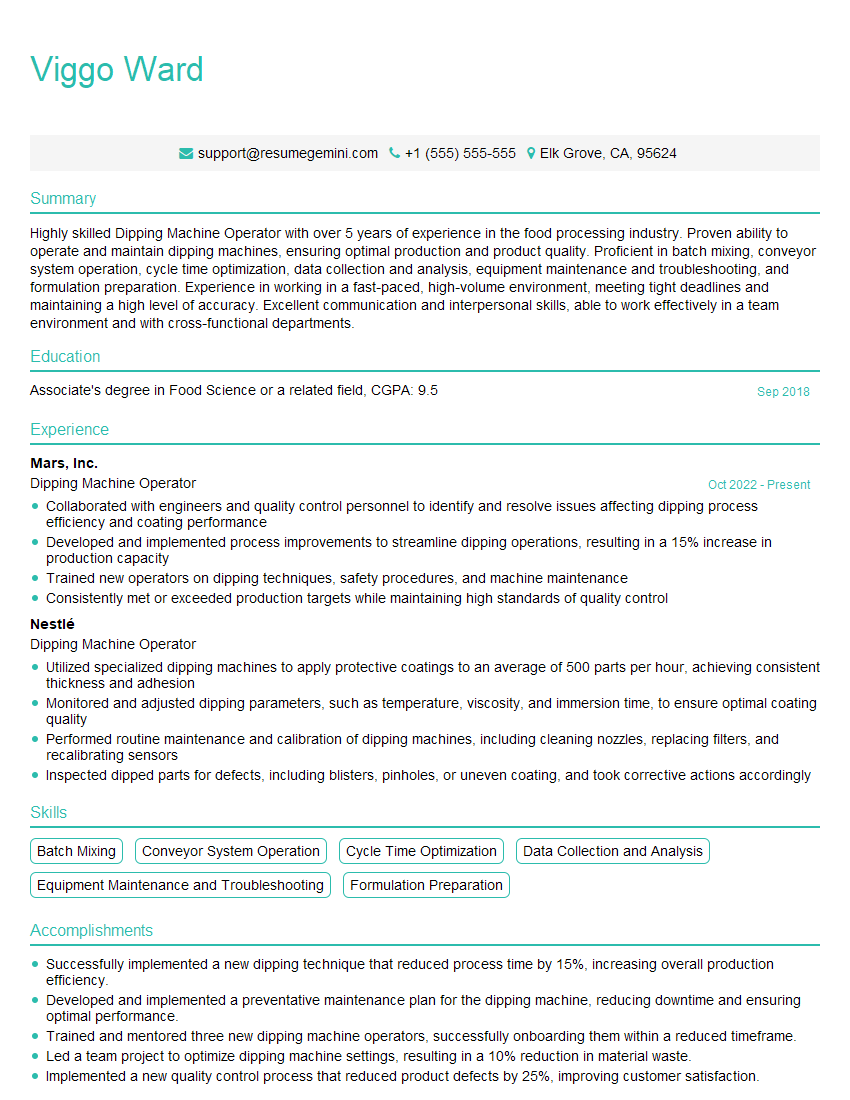

Viggo Ward

Dipping Machine Operator

Summary

Highly skilled Dipping Machine Operator with over 5 years of experience in the food processing industry. Proven ability to operate and maintain dipping machines, ensuring optimal production and product quality. Proficient in batch mixing, conveyor system operation, cycle time optimization, data collection and analysis, equipment maintenance and troubleshooting, and formulation preparation. Experience in working in a fast-paced, high-volume environment, meeting tight deadlines and maintaining a high level of accuracy. Excellent communication and interpersonal skills, able to work effectively in a team environment and with cross-functional departments.

Education

Associate’s degree in Food Science or a related field

September 2018

Skills

- Batch Mixing

- Conveyor System Operation

- Cycle Time Optimization

- Data Collection and Analysis

- Equipment Maintenance and Troubleshooting

- Formulation Preparation

Work Experience

Dipping Machine Operator

- Collaborated with engineers and quality control personnel to identify and resolve issues affecting dipping process efficiency and coating performance

- Developed and implemented process improvements to streamline dipping operations, resulting in a 15% increase in production capacity

- Trained new operators on dipping techniques, safety procedures, and machine maintenance

- Consistently met or exceeded production targets while maintaining high standards of quality control

Dipping Machine Operator

- Utilized specialized dipping machines to apply protective coatings to an average of 500 parts per hour, achieving consistent thickness and adhesion

- Monitored and adjusted dipping parameters, such as temperature, viscosity, and immersion time, to ensure optimal coating quality

- Performed routine maintenance and calibration of dipping machines, including cleaning nozzles, replacing filters, and recalibrating sensors

- Inspected dipped parts for defects, including blisters, pinholes, or uneven coating, and took corrective actions accordingly

Accomplishments

- Successfully implemented a new dipping technique that reduced process time by 15%, increasing overall production efficiency.

- Developed and implemented a preventative maintenance plan for the dipping machine, reducing downtime and ensuring optimal performance.

- Trained and mentored three new dipping machine operators, successfully onboarding them within a reduced timeframe.

- Led a team project to optimize dipping machine settings, resulting in a 10% reduction in material waste.

- Implemented a new quality control process that reduced product defects by 25%, improving customer satisfaction.

Awards

- Awarded Operator of the Quarter three consecutive quarters for outstanding performance and efficiency on the dipping machine.

- Recognized for highest quality output in the department, with zero defects reported for a continuous sixmonth period.

- Received Employee of the Year award for exceptional contributions to the dipping machine production line.

Certificates

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

- Lean Manufacturing Certification

- Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dipping Machine Operator

- Highlight your experience in operating and maintaining dipping machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and product quality.

- Showcase your knowledge of batch mixing, formulation preparation, and data analysis.

- Emphasize your ability to work in a fast-paced, high-volume environment and meet tight deadlines.

Essential Experience Highlights for a Strong Dipping Machine Operator Resume

- Operate and maintain dipping machines, ensuring optimal production and product quality.

- Perform batch mixing and formulation preparation according to established procedures.

- Monitor conveyor systems and make adjustments to ensure smooth operation.

- Collect and analyze data to identify and resolve production issues.

- Conduct routine maintenance and troubleshooting of dipping machines and related equipment.

- Adhere to all safety protocols and maintain a clean and organized work environment.

- Work closely with other team members to ensure efficient and timely production.

Frequently Asked Questions (FAQ’s) For Dipping Machine Operator

What are the key skills required to be a Dipping Machine Operator?

The key skills required to be a Dipping Machine Operator include operating and maintaining dipping machines, batch mixing, conveyor system operation, cycle time optimization, data collection and analysis, equipment maintenance and troubleshooting, and formulation preparation.

What are the job responsibilities of a Dipping Machine Operator?

The job responsibilities of a Dipping Machine Operator include operating and maintaining dipping machines, performing batch mixing and formulation preparation, monitoring conveyor systems, collecting and analyzing data, conducting routine maintenance and troubleshooting, adhering to safety protocols, and working closely with other team members.

What is the work environment of a Dipping Machine Operator like?

Dipping Machine Operators typically work in a fast-paced, high-volume production environment. They must be able to work independently and as part of a team, and they must be able to meet tight deadlines.

What are the career prospects for a Dipping Machine Operator?

Dipping Machine Operators can advance to positions such as Production Supervisor, Quality Control Manager, or Plant Manager.

What is the salary range for a Dipping Machine Operator?

The salary range for a Dipping Machine Operator can vary depending on experience, location, and company size. According to Indeed, the average salary for a Dipping Machine Operator in the United States is $35,000 per year.

What are the educational requirements for a Dipping Machine Operator?

Most Dipping Machine Operators have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in food science or a related field.