Are you a seasoned Extrusion Machine Operator seeking a new career path? Discover our professionally built Extrusion Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

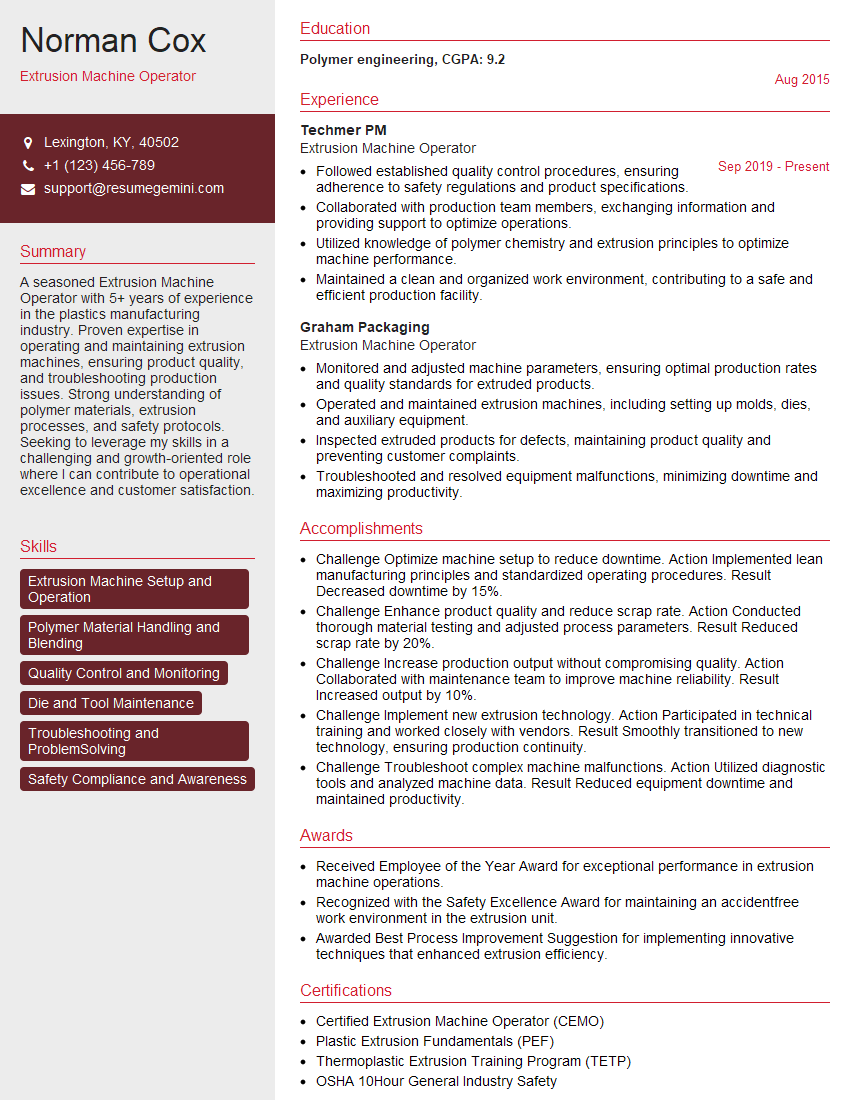

Norman Cox

Extrusion Machine Operator

Summary

A seasoned Extrusion Machine Operator with 5+ years of experience in the plastics manufacturing industry. Proven expertise in operating and maintaining extrusion machines, ensuring product quality, and troubleshooting production issues. Strong understanding of polymer materials, extrusion processes, and safety protocols. Seeking to leverage my skills in a challenging and growth-oriented role where I can contribute to operational excellence and customer satisfaction.

Education

Polymer engineering

August 2015

Skills

- Extrusion Machine Setup and Operation

- Polymer Material Handling and Blending

- Quality Control and Monitoring

- Die and Tool Maintenance

- Troubleshooting and ProblemSolving

- Safety Compliance and Awareness

Work Experience

Extrusion Machine Operator

- Followed established quality control procedures, ensuring adherence to safety regulations and product specifications.

- Collaborated with production team members, exchanging information and providing support to optimize operations.

- Utilized knowledge of polymer chemistry and extrusion principles to optimize machine performance.

- Maintained a clean and organized work environment, contributing to a safe and efficient production facility.

Extrusion Machine Operator

- Monitored and adjusted machine parameters, ensuring optimal production rates and quality standards for extruded products.

- Operated and maintained extrusion machines, including setting up molds, dies, and auxiliary equipment.

- Inspected extruded products for defects, maintaining product quality and preventing customer complaints.

- Troubleshooted and resolved equipment malfunctions, minimizing downtime and maximizing productivity.

Accomplishments

- Challenge Optimize machine setup to reduce downtime. Action Implemented lean manufacturing principles and standardized operating procedures. Result Decreased downtime by 15%.

- Challenge Enhance product quality and reduce scrap rate. Action Conducted thorough material testing and adjusted process parameters. Result Reduced scrap rate by 20%.

- Challenge Increase production output without compromising quality. Action Collaborated with maintenance team to improve machine reliability. Result Increased output by 10%.

- Challenge Implement new extrusion technology. Action Participated in technical training and worked closely with vendors. Result Smoothly transitioned to new technology, ensuring production continuity.

- Challenge Troubleshoot complex machine malfunctions. Action Utilized diagnostic tools and analyzed machine data. Result Reduced equipment downtime and maintained productivity.

Awards

- Received Employee of the Year Award for exceptional performance in extrusion machine operations.

- Recognized with the Safety Excellence Award for maintaining an accidentfree work environment in the extrusion unit.

- Awarded Best Process Improvement Suggestion for implementing innovative techniques that enhanced extrusion efficiency.

Certificates

- Certified Extrusion Machine Operator (CEMO)

- Plastic Extrusion Fundamentals (PEF)

- Thermoplastic Extrusion Training Program (TETP)

- OSHA 10Hour General Industry Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Extrusion Machine Operator

- Quantify your accomplishments with specific metrics and results.

- Highlight any experience or certifications in quality control or process improvement.

- Emphasize your ability to work independently and as part of a team.

- Showcase your knowledge of different types of extrusion machines and polymers.

Essential Experience Highlights for a Strong Extrusion Machine Operator Resume

- Set up and operate extrusion machines according to specifications, ensuring optimal production efficiency and product quality.

- Handle and blend polymer materials, ensuring proper material composition and consistency.

- Monitor and control extrusion processes, making adjustments as needed to maintain product specifications and minimize defects.

- Inspect and maintain dies and tools, ensuring proper alignment and functionality to prevent production downtime.

- Troubleshoot and resolve production issues, implementing corrective actions to minimize downtime and maintain production goals.

- Ensure compliance with safety protocols, including proper use of personal protective equipment, machine guarding, and hazardous material handling.

- Collaborate with maintenance and engineering teams to support machine upgrades and process improvements.

Frequently Asked Questions (FAQ’s) For Extrusion Machine Operator

What are the primary responsibilities of an Extrusion Machine Operator?

Extrusion Machine Operators are responsible for operating and maintaining extrusion machines, handling and blending polymer materials, monitoring and controlling extrusion processes, inspecting and maintaining dies and tools, troubleshooting production issues, and ensuring compliance with safety protocols.

What are the educational requirements for an Extrusion Machine Operator?

While formal education requirements may vary, many Extrusion Machine Operators hold a high school diploma or equivalent, with some pursuing an associate’s degree or certification in polymer engineering or a related field.

What are the key skills required for an Extrusion Machine Operator?

Essential skills for Extrusion Machine Operators include proficiency in extrusion machine setup and operation, polymer material handling and blending, quality control and monitoring, die and tool maintenance, troubleshooting and problem-solving, and safety compliance and awareness.

What are the career prospects for an Extrusion Machine Operator?

Extrusion Machine Operators can advance their careers by gaining experience and developing specialized skills. They may become supervisors, quality control inspectors, or production managers. With additional education or training, they can pursue roles in engineering or research and development.

What is the average salary for an Extrusion Machine Operator?

According to Indeed, the average salary for an Extrusion Machine Operator in the United States is around $55,000 per year. However, salaries may vary depending on experience, location, and industry.

What are the safety precautions that Extrusion Machine Operators must follow?

Extrusion Machine Operators must adhere to strict safety protocols, including wearing proper protective gear, following lockout/tagout procedures, and being aware of potential hazards associated with working with machinery and molten materials.