Are you a seasoned Hot Press Operator seeking a new career path? Discover our professionally built Hot Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

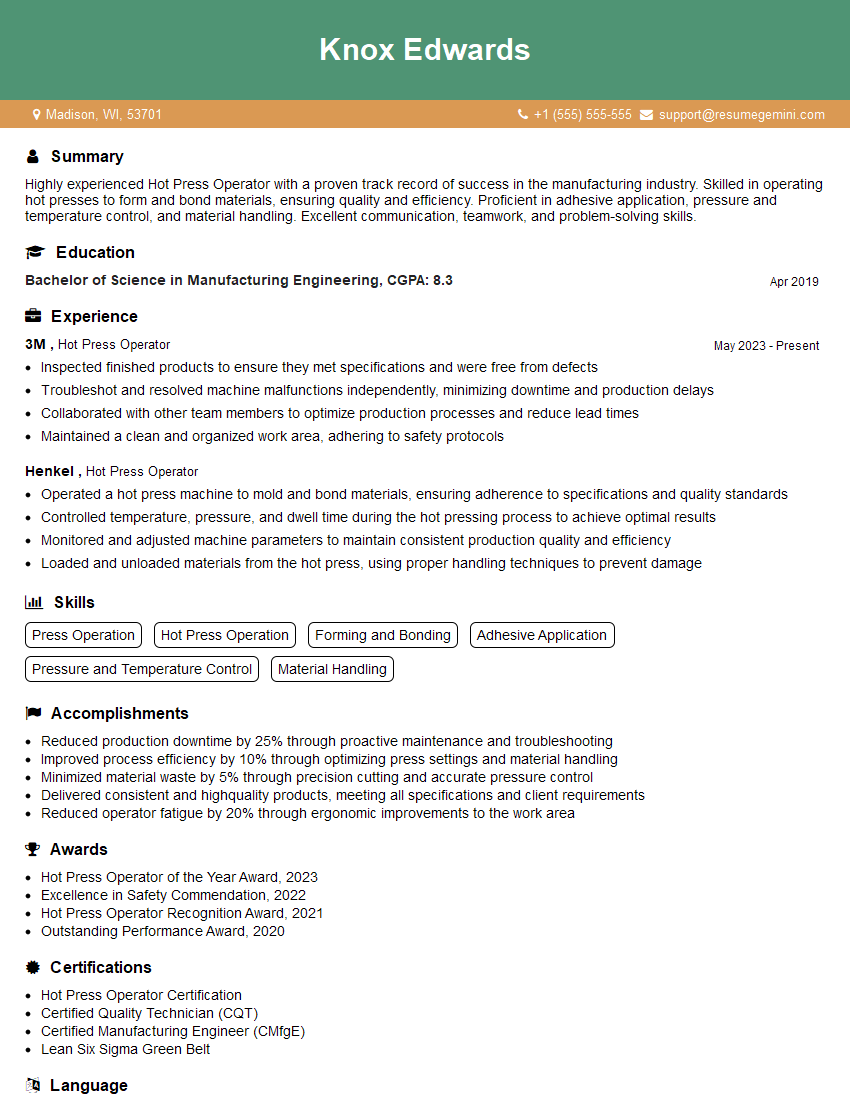

Knox Edwards

Hot Press Operator

Summary

Highly experienced Hot Press Operator with a proven track record of success in the manufacturing industry. Skilled in operating hot presses to form and bond materials, ensuring quality and efficiency. Proficient in adhesive application, pressure and temperature control, and material handling. Excellent communication, teamwork, and problem-solving skills.

Education

Bachelor of Science in Manufacturing Engineering

April 2019

Skills

- Press Operation

- Hot Press Operation

- Forming and Bonding

- Adhesive Application

- Pressure and Temperature Control

- Material Handling

Work Experience

Hot Press Operator

- Inspected finished products to ensure they met specifications and were free from defects

- Troubleshot and resolved machine malfunctions independently, minimizing downtime and production delays

- Collaborated with other team members to optimize production processes and reduce lead times

- Maintained a clean and organized work area, adhering to safety protocols

Hot Press Operator

- Operated a hot press machine to mold and bond materials, ensuring adherence to specifications and quality standards

- Controlled temperature, pressure, and dwell time during the hot pressing process to achieve optimal results

- Monitored and adjusted machine parameters to maintain consistent production quality and efficiency

- Loaded and unloaded materials from the hot press, using proper handling techniques to prevent damage

Accomplishments

- Reduced production downtime by 25% through proactive maintenance and troubleshooting

- Improved process efficiency by 10% through optimizing press settings and material handling

- Minimized material waste by 5% through precision cutting and accurate pressure control

- Delivered consistent and highquality products, meeting all specifications and client requirements

- Reduced operator fatigue by 20% through ergonomic improvements to the work area

Awards

- Hot Press Operator of the Year Award, 2023

- Excellence in Safety Commendation, 2022

- Hot Press Operator Recognition Award, 2021

- Outstanding Performance Award, 2020

Certificates

- Hot Press Operator Certification

- Certified Quality Technician (CQT)

- Certified Manufacturing Engineer (CMfgE)

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hot Press Operator

- Quantify your accomplishments whenever possible. For example, instead of saying “I operated hot presses,” say “I operated hot presses to produce X number of units per hour, resulting in a Y% increase in productivity.”

- Highlight your experience with specific materials and equipment. For example, mention the types of adhesives you have worked with and the brands of hot presses you are familiar with.

- Emphasize your commitment to quality and safety. For example, mention any certifications you have obtained or any safety protocols you have implemented.

- Proofread your resume carefully for any errors. A well-written resume will make you stand out from other candidates.

Essential Experience Highlights for a Strong Hot Press Operator Resume

- Operate hot presses to form and bond materials according to specifications.

- Control pressure, temperature, and adhesive application to ensure optimal bonding.

- Handle materials safely and efficiently, minimizing waste and maximizing productivity.

- Monitor equipment performance and make adjustments as needed to maintain quality standards.

- Inspect finished products to ensure they meet specifications.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

- Maintain a clean and organized work area, adhering to safety regulations.

Frequently Asked Questions (FAQ’s) For Hot Press Operator

What is a hot press operator?

A hot press operator is responsible for operating hot presses to form and bond materials. They control pressure, temperature, and adhesive application to ensure optimal bonding. Hot press operators also handle materials safely and efficiently, inspect finished products, and troubleshoot equipment malfunctions.

What skills are required to be a hot press operator?

Hot press operators typically need the following skills: press operation, hot press operation, forming and bonding, adhesive application, pressure and temperature control, material handling, communication, teamwork, and problem-solving.

What is the work environment of a hot press operator like?

Hot press operators typically work in manufacturing facilities. They may be exposed to heat, noise, and chemicals. They must be able to work independently and as part of a team.

What is the career outlook for hot press operators?

The job outlook for hot press operators is expected to be good. This is because hot presses are used in a variety of industries, including automotive, aerospace, and construction.

What is the salary range for hot press operators?

The salary range for hot press operators varies depending on experience, location, and company size. However, the median salary for hot press operators is around $40,000 per year.

What are the benefits of being a hot press operator?

There are several benefits to being a hot press operator, including job security, good pay, and opportunities for advancement. Hot press operators are also in demand in a variety of industries.