Are you a seasoned Rubber Tubing Splicer seeking a new career path? Discover our professionally built Rubber Tubing Splicer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

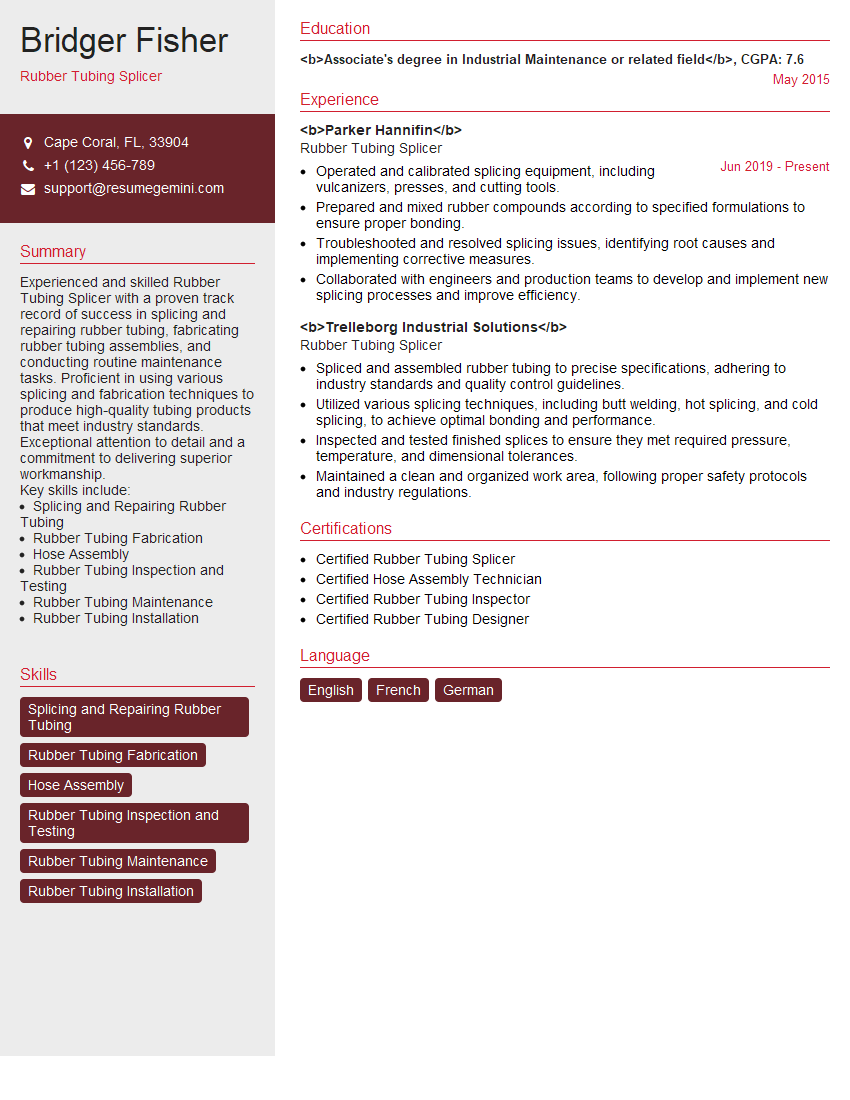

Bridger Fisher

Rubber Tubing Splicer

Summary

Experienced and skilled Rubber Tubing Splicer with a proven track record of success in splicing and repairing rubber tubing, fabricating rubber tubing assemblies, and conducting routine maintenance tasks. Proficient in using various splicing and fabrication techniques to produce high-quality tubing products that meet industry standards. Exceptional attention to detail and a commitment to delivering superior workmanship.

Key skills include:

Education

Associate’s degree in Industrial Maintenance or related field

May 2015

Skills

- Splicing and Repairing Rubber Tubing

- Rubber Tubing Fabrication

- Hose Assembly

- Rubber Tubing Inspection and Testing

- Rubber Tubing Maintenance

- Rubber Tubing Installation

Work Experience

Rubber Tubing Splicer

- Operated and calibrated splicing equipment, including vulcanizers, presses, and cutting tools.

- Prepared and mixed rubber compounds according to specified formulations to ensure proper bonding.

- Troubleshooted and resolved splicing issues, identifying root causes and implementing corrective measures.

- Collaborated with engineers and production teams to develop and implement new splicing processes and improve efficiency.

Rubber Tubing Splicer

- Spliced and assembled rubber tubing to precise specifications, adhering to industry standards and quality control guidelines.

- Utilized various splicing techniques, including butt welding, hot splicing, and cold splicing, to achieve optimal bonding and performance.

- Inspected and tested finished splices to ensure they met required pressure, temperature, and dimensional tolerances.

- Maintained a clean and organized work area, following proper safety protocols and industry regulations.

Certificates

- Certified Rubber Tubing Splicer

- Certified Hose Assembly Technician

- Certified Rubber Tubing Inspector

- Certified Rubber Tubing Designer

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rubber Tubing Splicer

- Highlight your experience in splicing and repairing rubber tubing, and quantify your accomplishments with specific metrics.

- Showcase your proficiency in using various splicing and fabrication techniques, and provide examples of complex projects you have completed.

- Emphasize your understanding of rubber tubing materials and their applications, and demonstrate your ability to select the appropriate tubing for specific requirements.

- Include keywords related to the rubber tubing industry, such as splicing, fabrication, hose assembly, and quality control.

Essential Experience Highlights for a Strong Rubber Tubing Splicer Resume

- Splice and repair rubber tubing of various sizes and types, ensuring minimal downtime and optimal performance.

- Fabricate custom rubber tubing assemblies according to specifications, including cutting, bending, and joining.

- Assemble and install rubber hoses, ensuring proper connections and leak-free operation.

- Inspect and test rubber tubing assemblies to ensure they meet quality standards and customer requirements.

- Perform routine maintenance on rubber tubing systems, including cleaning, lubrication, and replacement of worn components.

- Troubleshoot and resolve issues with rubber tubing systems, minimizing downtime and maintaining operational efficiency.

Frequently Asked Questions (FAQ’s) For Rubber Tubing Splicer

What is the primary function of a Rubber Tubing Splicer?

The primary function of a Rubber Tubing Splicer is to splice and repair rubber tubing of various sizes and types, ensuring minimal downtime and optimal performance.

What are the key skills required for a Rubber Tubing Splicer?

Key skills for a Rubber Tubing Splicer include splicing and repairing rubber tubing, fabricating rubber tubing assemblies, hose assembly, rubber tubing inspection and testing, rubber tubing maintenance, and rubber tubing installation.

What industries employ Rubber Tubing Splicers?

Rubber Tubing Splicers are employed in a variety of industries, including manufacturing, automotive, construction, and aerospace.

What are the career prospects for a Rubber Tubing Splicer?

With experience and additional training, Rubber Tubing Splicers can advance to positions such as Rubber Tubing Supervisor or Rubber Tubing Manager.

What are the educational requirements for a Rubber Tubing Splicer?

While formal education requirements vary, many Rubber Tubing Splicers hold an associate’s degree in Industrial Maintenance or a related field.

What are the typical working conditions for a Rubber Tubing Splicer?

Rubber Tubing Splicers typically work in industrial environments, which may involve exposure to noise, dust, and chemicals.

What safety precautions should be taken by a Rubber Tubing Splicer?

Rubber Tubing Splicers should wear appropriate safety gear, including gloves, eye protection, and respirators when necessary, and follow established safety protocols.