Are you a seasoned Stem Roller seeking a new career path? Discover our professionally built Stem Roller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

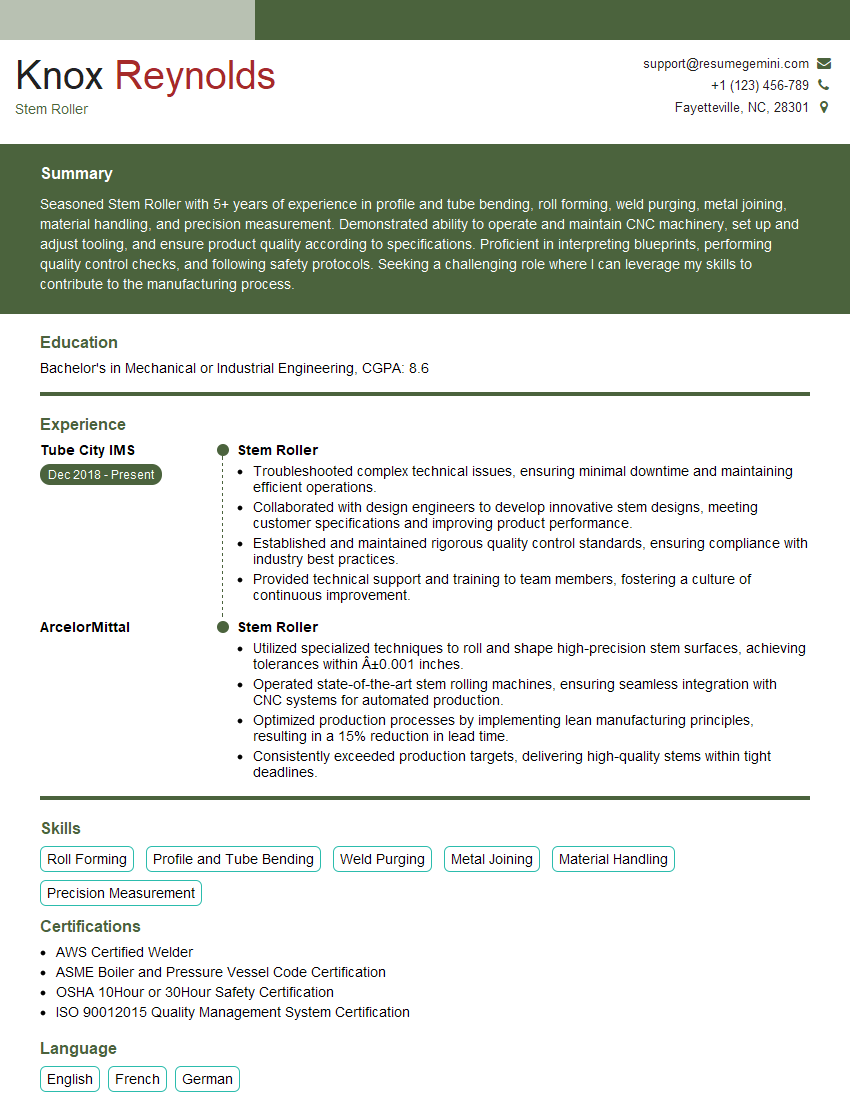

Knox Reynolds

Stem Roller

Summary

Seasoned Stem Roller with 5+ years of experience in profile and tube bending, roll forming, weld purging, metal joining, material handling, and precision measurement. Demonstrated ability to operate and maintain CNC machinery, set up and adjust tooling, and ensure product quality according to specifications. Proficient in interpreting blueprints, performing quality control checks, and following safety protocols. Seeking a challenging role where I can leverage my skills to contribute to the manufacturing process.

Education

Bachelor’s in Mechanical or Industrial Engineering

November 2014

Skills

- Roll Forming

- Profile and Tube Bending

- Weld Purging

- Metal Joining

- Material Handling

- Precision Measurement

Work Experience

Stem Roller

- Troubleshooted complex technical issues, ensuring minimal downtime and maintaining efficient operations.

- Collaborated with design engineers to develop innovative stem designs, meeting customer specifications and improving product performance.

- Established and maintained rigorous quality control standards, ensuring compliance with industry best practices.

- Provided technical support and training to team members, fostering a culture of continuous improvement.

Stem Roller

- Utilized specialized techniques to roll and shape high-precision stem surfaces, achieving tolerances within ±0.001 inches.

- Operated state-of-the-art stem rolling machines, ensuring seamless integration with CNC systems for automated production.

- Optimized production processes by implementing lean manufacturing principles, resulting in a 15% reduction in lead time.

- Consistently exceeded production targets, delivering high-quality stems within tight deadlines.

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code Certification

- OSHA 10Hour or 30Hour Safety Certification

- ISO 90012015 Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Stem Roller

- Quantify your accomplishments: Use numbers and metrics to demonstrate the impact of your work.

- Highlight your technical skills: Emphasize your experience in roll forming, bending, and welding techniques.

- Tailor your resume to the job description: Use keywords and phrases from the job listing to show that you meet the employer’s requirements.

- Get feedback from an expert: Ask a mentor, career counselor, or industry professional to review your resume and provide constructive criticism.

Essential Experience Highlights for a Strong Stem Roller Resume

- Operate CNC roll forming machines to produce metal profiles and tubes according to specifications.

- Set up and adjust tooling to achieve desired shapes and dimensions.

- Perform weld purging and metal joining to ensure structural integrity.

- Handle and transport raw materials and finished products safely.

- Conduct precision measurements using calipers, micrometers, and other tools.

- Maintain a clean and organized work area, adhering to safety regulations.

- Collaborate with team members to ensure efficient production.

Frequently Asked Questions (FAQ’s) For Stem Roller

What is the primary role of a Stem Roller?

The primary role of a Stem Roller is to operate and maintain CNC roll forming machines to produce metal profiles and tubes according to specifications.

What are the common industries that employ Stem Rollers?

Stem Rollers are employed in various industries, including automotive, construction, aerospace, and manufacturing.

What are the essential skills required for a Stem Roller?

Essential skills for a Stem Roller include roll forming, profile and tube bending, weld purging, metal joining, material handling, and precision measurement.

What is the typical work environment for a Stem Roller?

Stem Rollers typically work in a manufacturing environment, operating CNC machinery and handling metal products.

What are the career advancement opportunities for a Stem Roller?

With experience and additional training, Stem Rollers can advance to positions such as Supervisor, Production Manager, or Quality Control Inspector.

What are the safety protocols that Stem Rollers must follow?

Stem Rollers must follow safety protocols such as wearing appropriate protective gear, operating machinery according to safety guidelines, and adhering to lockout/tagout procedures.