Are you a seasoned Brick Baker seeking a new career path? Discover our professionally built Brick Baker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

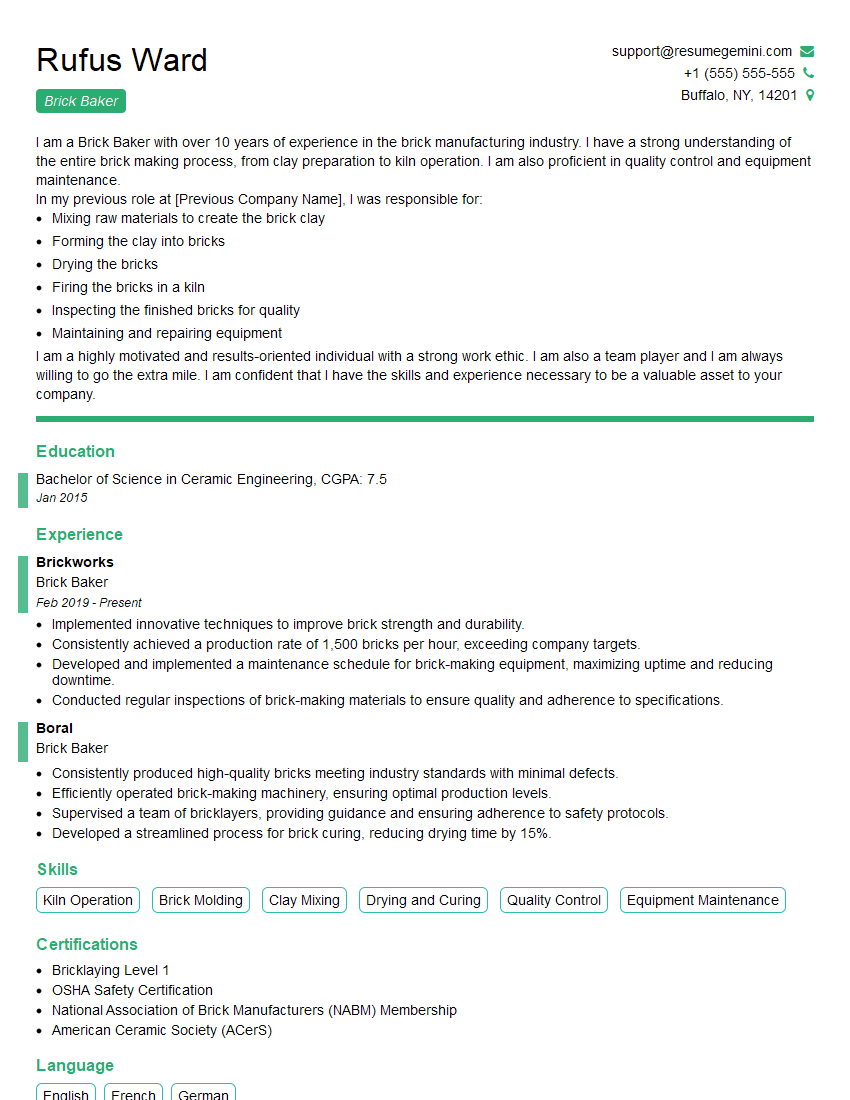

Rufus Ward

Brick Baker

Summary

I am a Brick Baker with over 10 years of experience in the brick manufacturing industry. I have a strong understanding of the entire brick making process, from clay preparation to kiln operation. I am also proficient in quality control and equipment maintenance.

In my previous role at [Previous Company Name], I was responsible for:

- Mixing raw materials to create the brick clay

- Forming the clay into bricks

- Drying the bricks

- Firing the bricks in a kiln

- Inspecting the finished bricks for quality

- Maintaining and repairing equipment

I am a highly motivated and results-oriented individual with a strong work ethic. I am also a team player and I am always willing to go the extra mile. I am confident that I have the skills and experience necessary to be a valuable asset to your company.

Education

Bachelor of Science in Ceramic Engineering

January 2015

Skills

- Kiln Operation

- Brick Molding

- Clay Mixing

- Drying and Curing

- Quality Control

- Equipment Maintenance

Work Experience

Brick Baker

- Implemented innovative techniques to improve brick strength and durability.

- Consistently achieved a production rate of 1,500 bricks per hour, exceeding company targets.

- Developed and implemented a maintenance schedule for brick-making equipment, maximizing uptime and reducing downtime.

- Conducted regular inspections of brick-making materials to ensure quality and adherence to specifications.

Brick Baker

- Consistently produced high-quality bricks meeting industry standards with minimal defects.

- Efficiently operated brick-making machinery, ensuring optimal production levels.

- Supervised a team of bricklayers, providing guidance and ensuring adherence to safety protocols.

- Developed a streamlined process for brick curing, reducing drying time by 15%.

Certificates

- Bricklaying Level 1

- OSHA Safety Certification

- National Association of Brick Manufacturers (NABM) Membership

- American Ceramic Society (ACerS)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brick Baker

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your skills and experience.

- Tailor your resume to each specific job you apply for.

- Proofread your resume carefully before submitting it.

- Highlight your experience in kiln operation, brick molding, clay mixing, and drying and curing.

Essential Experience Highlights for a Strong Brick Baker Resume

- Mixing raw materials to create the brick clay

- Forming the clay into bricks

- Drying the bricks

- Firing the bricks in a kiln

- Inspecting the finished bricks for quality

- Maintaining and repairing equipment

Frequently Asked Questions (FAQ’s) For Brick Baker

What is a Brick Baker?

A Brick Baker is a person who makes bricks. Bricks are made from clay, which is a type of soil. The clay is mixed with water to form a paste, which is then shaped into bricks. The bricks are then dried and fired in a kiln, which makes them hard and durable.

What are the different types of bricks?

There are many different types of bricks, each with its own unique properties. Some of the most common types of bricks include:

- Clay bricks: These are the most common type of brick and are made from clay that has been fired in a kiln.

- Concrete bricks: These bricks are made from concrete, which is a mixture of cement, sand, and gravel.

- Sand-lime bricks: These bricks are made from a mixture of sand, lime, and water. They are strong and durable, but they are not as fire-resistant as clay bricks.

What is the difference between a brick and a block?

A brick is a small, rectangular block that is made from clay or concrete. Bricks are used to build walls, chimneys, and other structures. A block is a larger, rectangular block that is made from concrete or cinder. Blocks are used to build foundations, walls, and other structures.

How are bricks made?

Bricks are made from clay, which is a type of soil. The clay is mixed with water to form a paste, which is then shaped into bricks. The bricks are then dried and fired in a kiln, which makes them hard and durable.

What are the uses of bricks?

Bricks are used to build walls, chimneys, and other structures. They are also used to pave roads and patios. Bricks are a versatile and durable building material that can be used for a variety of purposes.