Are you a seasoned Calciner Operator seeking a new career path? Discover our professionally built Calciner Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

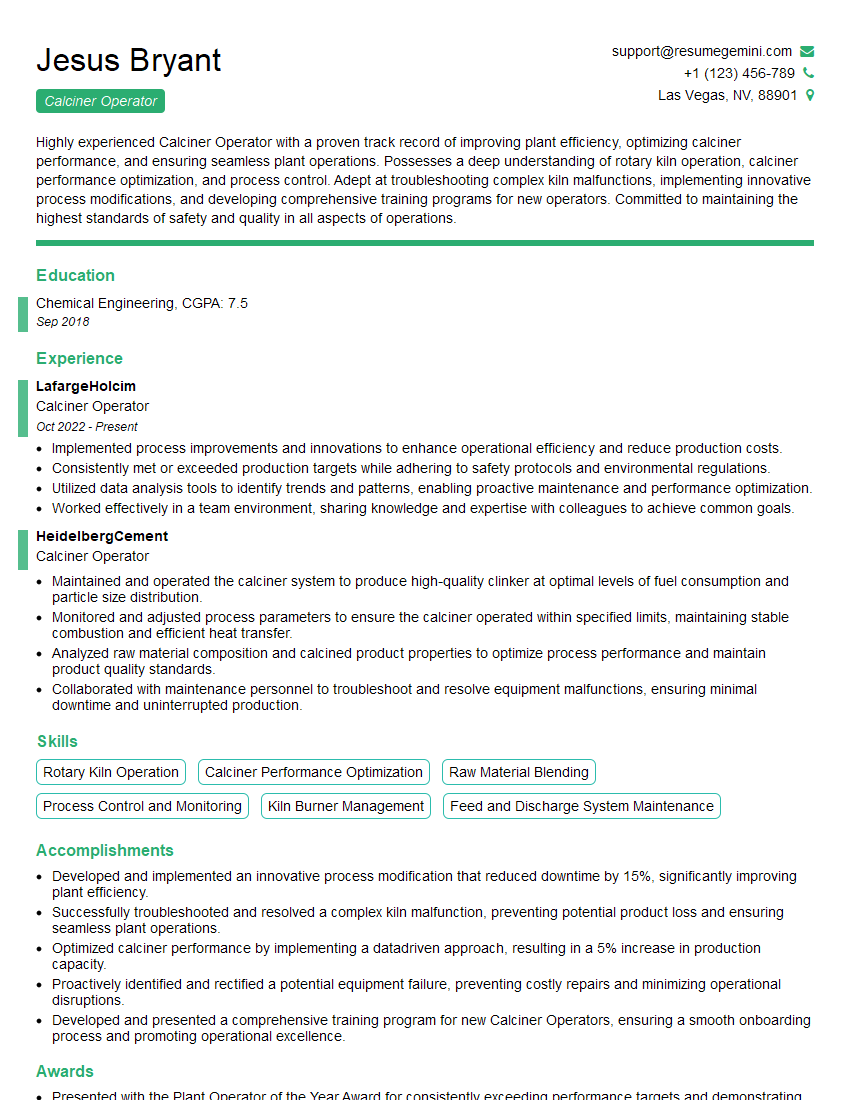

Jesus Bryant

Calciner Operator

Summary

Highly experienced Calciner Operator with a proven track record of improving plant efficiency, optimizing calciner performance, and ensuring seamless plant operations. Possesses a deep understanding of rotary kiln operation, calciner performance optimization, and process control. Adept at troubleshooting complex kiln malfunctions, implementing innovative process modifications, and developing comprehensive training programs for new operators. Committed to maintaining the highest standards of safety and quality in all aspects of operations.

Education

Chemical Engineering

September 2018

Skills

- Rotary Kiln Operation

- Calciner Performance Optimization

- Raw Material Blending

- Process Control and Monitoring

- Kiln Burner Management

- Feed and Discharge System Maintenance

Work Experience

Calciner Operator

- Implemented process improvements and innovations to enhance operational efficiency and reduce production costs.

- Consistently met or exceeded production targets while adhering to safety protocols and environmental regulations.

- Utilized data analysis tools to identify trends and patterns, enabling proactive maintenance and performance optimization.

- Worked effectively in a team environment, sharing knowledge and expertise with colleagues to achieve common goals.

Calciner Operator

- Maintained and operated the calciner system to produce high-quality clinker at optimal levels of fuel consumption and particle size distribution.

- Monitored and adjusted process parameters to ensure the calciner operated within specified limits, maintaining stable combustion and efficient heat transfer.

- Analyzed raw material composition and calcined product properties to optimize process performance and maintain product quality standards.

- Collaborated with maintenance personnel to troubleshoot and resolve equipment malfunctions, ensuring minimal downtime and uninterrupted production.

Accomplishments

- Developed and implemented an innovative process modification that reduced downtime by 15%, significantly improving plant efficiency.

- Successfully troubleshooted and resolved a complex kiln malfunction, preventing potential product loss and ensuring seamless plant operations.

- Optimized calciner performance by implementing a datadriven approach, resulting in a 5% increase in production capacity.

- Proactively identified and rectified a potential equipment failure, preventing costly repairs and minimizing operational disruptions.

- Developed and presented a comprehensive training program for new Calciner Operators, ensuring a smooth onboarding process and promoting operational excellence.

Awards

- Presented with the Plant Operator of the Year Award for consistently exceeding performance targets and demonstrating exceptional safety protocols.

- Received the Safety Excellence Award for maintaining an impeccable safety record and consistently adhering to all safety regulations.

- Honored with the Production Excellence Award for consistently delivering highquality clinker output within specified parameters.

- Recognized with the Outstanding Performance Award for exceeding targets and maintaining a clean and organized work environment.

Certificates

- Certified Kiln Operator (CKO)

- OSHA 10Hour General Industry Safety

- EPA Clean Air Act Regulations

- Certified Maintenance and Reliability Technician (CMRT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Calciner Operator

- Highlight your technical skills and experience in rotary kiln operation, calciner performance optimization, and process control.

- Quantify your accomplishments with specific metrics and data to demonstrate your impact on plant efficiency and productivity.

- Showcase your problem-solving abilities and experience in troubleshooting and resolving complex kiln malfunctions.

- Emphasize your commitment to safety and quality by highlighting your adherence to industry standards and best practices.

- Consider obtaining industry certifications, such as the CII Carbon Reduction Manager (CRM) certification, to enhance your credibility.

Essential Experience Highlights for a Strong Calciner Operator Resume

- Operate and monitor rotary kilns and calciners to ensure optimal performance and product quality.

- Control and adjust process parameters, such as temperature, feed rate, and kiln speed, to optimize calciner efficiency and minimize downtime.

- Troubleshoot and resolve kiln malfunctions and equipment failures to prevent production losses and ensure safe plant operations.

- Perform preventive maintenance and repairs on kilns, calciners, and associated equipment to maintain optimal performance and prevent breakdowns.

- Monitor and maintain process control systems, including PLCs and DCSs, to ensure accurate data collection and process optimization.

- Develop and implement process improvements to increase production capacity, reduce costs, and minimize environmental impact.

- Train and mentor new Calciner Operators to ensure a smooth onboarding process and promote operational excellence.

Frequently Asked Questions (FAQ’s) For Calciner Operator

What is the primary role of a Calciner Operator?

The primary role of a Calciner Operator is to operate and monitor rotary kilns and calciners to produce calcined materials, such as cement, lime, and other minerals. They ensure optimal performance and product quality by controlling and adjusting process parameters, troubleshooting malfunctions, and performing preventive maintenance.

What are the key skills required to be a successful Calciner Operator?

Successful Calciner Operators possess a strong understanding of rotary kiln operation, calciner performance optimization, and process control. They are proficient in troubleshooting and resolving kiln malfunctions, performing preventive maintenance, and implementing process improvements. Additionally, they have excellent communication and teamwork skills, and a commitment to safety and quality.

What are the career advancement opportunities for Calciner Operators?

With experience and additional training, Calciner Operators can advance to roles such as Kiln Supervisor, Plant Manager, or Technical Manager. They may also specialize in specific areas, such as process optimization, kiln maintenance, or environmental compliance.

What is the work environment like for Calciner Operators?

Calciner Operators typically work in industrial settings, such as cement plants, lime plants, or mineral processing facilities. They may work in shifts and be exposed to noise, heat, and dust. However, modern plants are increasingly automated, providing a safer and more comfortable work environment.

What are the safety precautions that Calciner Operators must follow?

Calciner Operators must adhere to strict safety protocols to minimize risks in the industrial environment. These include wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and being aware of potential hazards such as rotating equipment, high temperatures, and chemical spills.

How can I prepare for a career as a Calciner Operator?

Aspiring Calciner Operators can prepare for a career in this field by obtaining a degree in Chemical Engineering or a related discipline. They can also gain practical experience through internships or entry-level positions in the cement or mineral processing industry.