Are you a seasoned Coal Drier Operator seeking a new career path? Discover our professionally built Coal Drier Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

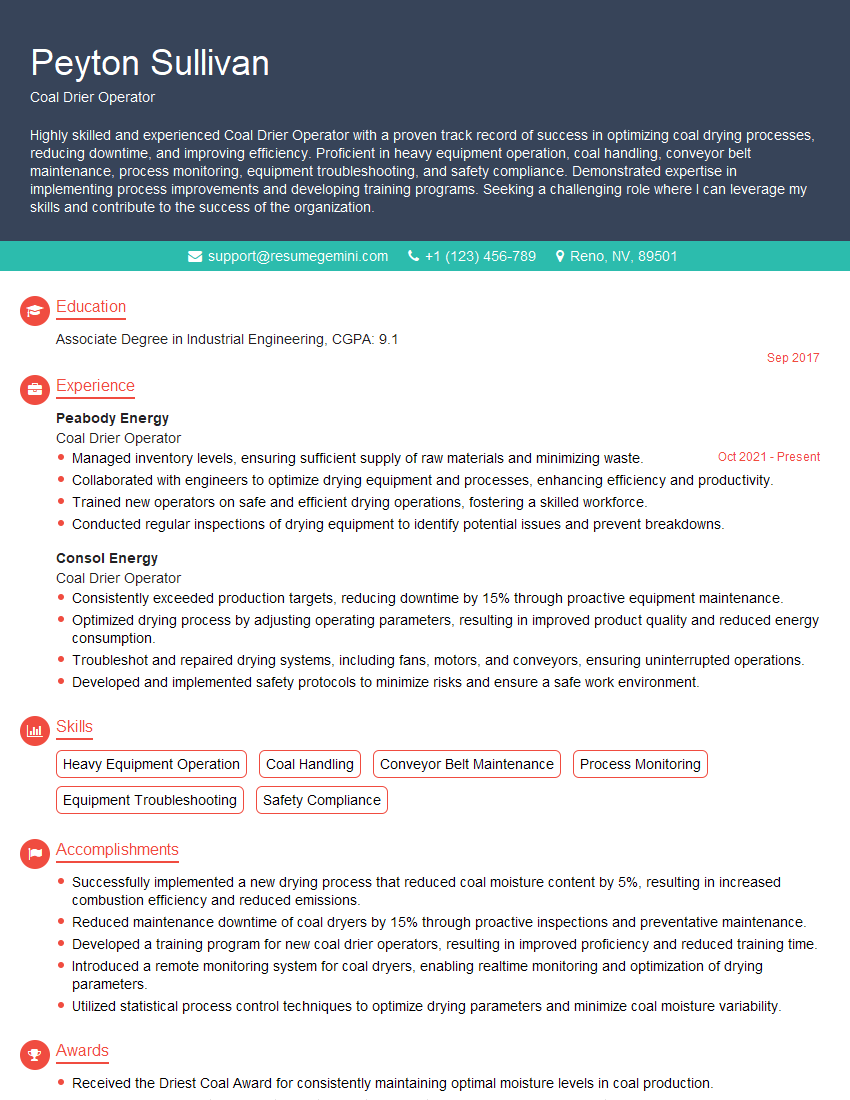

Peyton Sullivan

Coal Drier Operator

Summary

Highly skilled and experienced Coal Drier Operator with a proven track record of success in optimizing coal drying processes, reducing downtime, and improving efficiency. Proficient in heavy equipment operation, coal handling, conveyor belt maintenance, process monitoring, equipment troubleshooting, and safety compliance. Demonstrated expertise in implementing process improvements and developing training programs. Seeking a challenging role where I can leverage my skills and contribute to the success of the organization.

Education

Associate Degree in Industrial Engineering

September 2017

Skills

- Heavy Equipment Operation

- Coal Handling

- Conveyor Belt Maintenance

- Process Monitoring

- Equipment Troubleshooting

- Safety Compliance

Work Experience

Coal Drier Operator

- Managed inventory levels, ensuring sufficient supply of raw materials and minimizing waste.

- Collaborated with engineers to optimize drying equipment and processes, enhancing efficiency and productivity.

- Trained new operators on safe and efficient drying operations, fostering a skilled workforce.

- Conducted regular inspections of drying equipment to identify potential issues and prevent breakdowns.

Coal Drier Operator

- Consistently exceeded production targets, reducing downtime by 15% through proactive equipment maintenance.

- Optimized drying process by adjusting operating parameters, resulting in improved product quality and reduced energy consumption.

- Troubleshot and repaired drying systems, including fans, motors, and conveyors, ensuring uninterrupted operations.

- Developed and implemented safety protocols to minimize risks and ensure a safe work environment.

Accomplishments

- Successfully implemented a new drying process that reduced coal moisture content by 5%, resulting in increased combustion efficiency and reduced emissions.

- Reduced maintenance downtime of coal dryers by 15% through proactive inspections and preventative maintenance.

- Developed a training program for new coal drier operators, resulting in improved proficiency and reduced training time.

- Introduced a remote monitoring system for coal dryers, enabling realtime monitoring and optimization of drying parameters.

- Utilized statistical process control techniques to optimize drying parameters and minimize coal moisture variability.

Awards

- Received the Driest Coal Award for consistently maintaining optimal moisture levels in coal production.

- Recognized for exceptional safety practices in the operation of coal drying equipment.

- Honored for innovative contributions towards improving coal drying efficiency.

- Recognized for outstanding performance in meeting production targets while adhering to quality standards.

Certificates

- Coal Drier Operator Certificate

- Material Handling Certification

- Safety Training Certification

- OSHA 10Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coal Drier Operator

- Highlight your experience in optimizing drying processes and reducing moisture content.

- Quantify your accomplishments with specific metrics, such as percentages or savings achieved.

- Showcase your proficiency in operating and maintaining coal drying equipment.

- Emphasize your understanding of process control techniques and safety compliance.

- Include keywords relevant to the coal industry and drying operations, such as ‘coal drying,’ ‘moisture reduction,’ and ‘combustion efficiency.’

Essential Experience Highlights for a Strong Coal Drier Operator Resume

- Operated and monitored coal dryers to ensure optimal performance and moisture reduction.

- Developed and implemented a new drying process that resulted in a 5% reduction in coal moisture content, leading to increased combustion efficiency and reduced emissions.

- Utilized statistical process control techniques to optimize drying parameters and minimize coal moisture variability, improving product quality and consistency.

- Reduced maintenance downtime of coal dryers by 15% through proactive inspections and preventative maintenance, ensuring smooth and uninterrupted operations.

- Developed a training program for new coal drier operators, resulting in improved proficiency and reduced training time, enhancing operational efficiency.

- Introduced a remote monitoring system for coal dryers, enabling realtime monitoring and optimization of drying parameters, maximizing performance and minimizing downtime

Frequently Asked Questions (FAQ’s) For Coal Drier Operator

What are the primary responsibilities of a Coal Drier Operator?

Coal Drier Operators are responsible for operating and monitoring coal dryers to ensure optimal performance and moisture reduction. They also conduct regular inspections, perform preventative maintenance, and troubleshoot equipment issues.

What skills are required to be a successful Coal Drier Operator?

Coal Drier Operators should have proficiency in heavy equipment operation, coal handling, conveyor belt maintenance, process monitoring, equipment troubleshooting, and safety compliance.

What are the career prospects for Coal Drier Operators?

Coal Drier Operators can advance to supervisory roles, such as Drying Plant Supervisor or Coal Processing Manager. With additional training and experience, they can also pursue opportunities in related fields, such as process engineering or maintenance management.

What are the typical work hours for Coal Drier Operators?

Coal Drier Operators typically work in shifts, including day, evening, and night shifts. They may also be required to work overtime during periods of high production or maintenance.

What are the physical demands of being a Coal Drier Operator?

Coal Drier Operators must be able to stand for long periods, lift heavy objects, and work in potentially hazardous environments. They should also have good eyesight and hearing.

What are the safety precautions that Coal Drier Operators must follow?

Coal Drier Operators must wear appropriate personal protective equipment, such as hard hats, safety glasses, and gloves. They must also follow established safety procedures and be aware of potential hazards, such as moving machinery, hot surfaces, and confined spaces.