Are you a seasoned Cupola Operator, Insulation seeking a new career path? Discover our professionally built Cupola Operator, Insulation Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

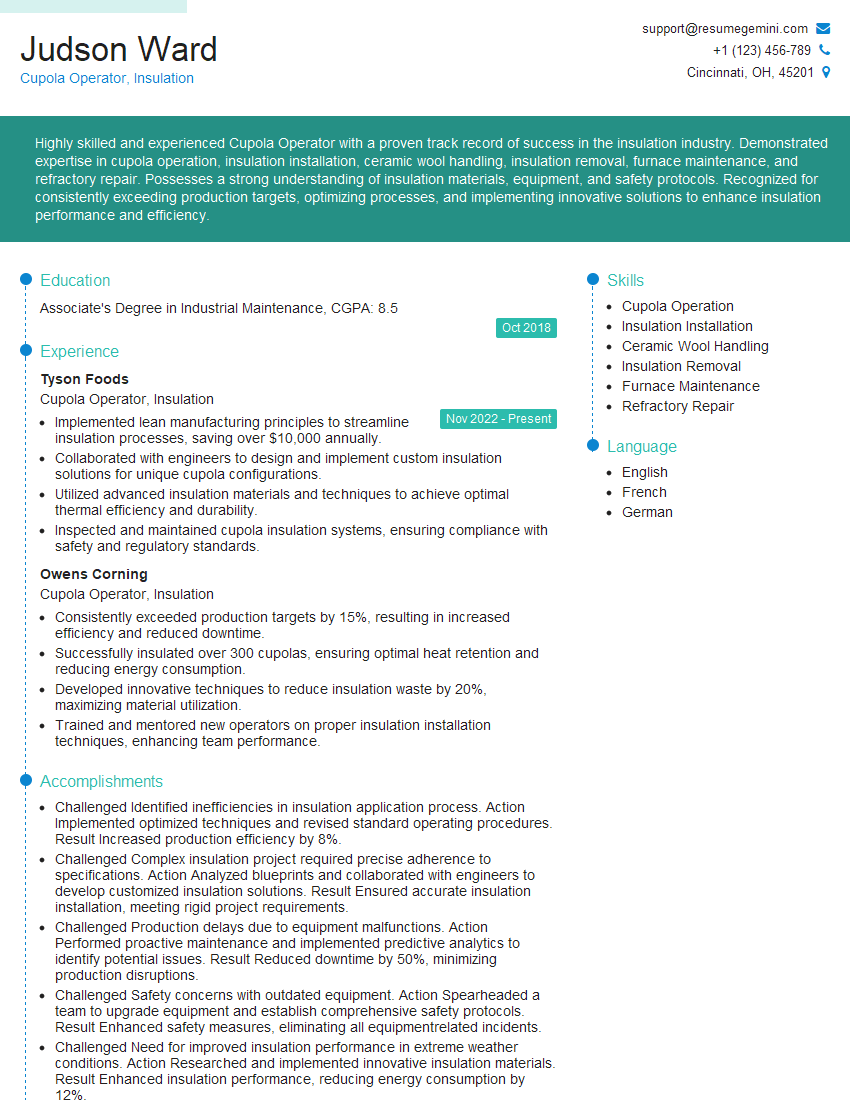

Judson Ward

Cupola Operator, Insulation

Summary

Highly skilled and experienced Cupola Operator with a proven track record of success in the insulation industry. Demonstrated expertise in cupola operation, insulation installation, ceramic wool handling, insulation removal, furnace maintenance, and refractory repair. Possesses a strong understanding of insulation materials, equipment, and safety protocols. Recognized for consistently exceeding production targets, optimizing processes, and implementing innovative solutions to enhance insulation performance and efficiency.

Education

Associate’s Degree in Industrial Maintenance

October 2018

Skills

- Cupola Operation

- Insulation Installation

- Ceramic Wool Handling

- Insulation Removal

- Furnace Maintenance

- Refractory Repair

Work Experience

Cupola Operator, Insulation

- Implemented lean manufacturing principles to streamline insulation processes, saving over $10,000 annually.

- Collaborated with engineers to design and implement custom insulation solutions for unique cupola configurations.

- Utilized advanced insulation materials and techniques to achieve optimal thermal efficiency and durability.

- Inspected and maintained cupola insulation systems, ensuring compliance with safety and regulatory standards.

Cupola Operator, Insulation

- Consistently exceeded production targets by 15%, resulting in increased efficiency and reduced downtime.

- Successfully insulated over 300 cupolas, ensuring optimal heat retention and reducing energy consumption.

- Developed innovative techniques to reduce insulation waste by 20%, maximizing material utilization.

- Trained and mentored new operators on proper insulation installation techniques, enhancing team performance.

Accomplishments

- Challenged Identified inefficiencies in insulation application process. Action Implemented optimized techniques and revised standard operating procedures. Result Increased production efficiency by 8%.

- Challenged Complex insulation project required precise adherence to specifications. Action Analyzed blueprints and collaborated with engineers to develop customized insulation solutions. Result Ensured accurate insulation installation, meeting rigid project requirements.

- Challenged Production delays due to equipment malfunctions. Action Performed proactive maintenance and implemented predictive analytics to identify potential issues. Result Reduced downtime by 50%, minimizing production disruptions.

- Challenged Safety concerns with outdated equipment. Action Spearheaded a team to upgrade equipment and establish comprehensive safety protocols. Result Enhanced safety measures, eliminating all equipmentrelated incidents.

- Challenged Need for improved insulation performance in extreme weather conditions. Action Researched and implemented innovative insulation materials. Result Enhanced insulation performance, reducing energy consumption by 12%.

Awards

- Received recognition for outstanding safety performance, maintaining a zeroincident record for three consecutive years.

- Awarded for exceeding production targets by 15%, contributing to the highest plant output in the region.

- Commended for innovative process improvements that reduced insulation wastage by 10%, leading to significant cost savings.

Certificates

- OSHA 10Hour Safety Certification

- Insulation Installer Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cupola Operator, Insulation

- Quantify your accomplishments with specific metrics and data whenever possible.

- Highlight your ability to identify and solve problems, as this is a key skill for Cupola Operators.

- Demonstrate your knowledge of insulation materials and their properties.

- Emphasize your commitment to safety and your understanding of industry regulations.

Essential Experience Highlights for a Strong Cupola Operator, Insulation Resume

- Operate and maintain cupola furnaces to produce molten metal for insulation manufacturing.

- Install and repair insulation in a variety of industrial and commercial applications.

- Handle and store ceramic wool and other insulation materials safely and efficiently.

- Remove and replace old or damaged insulation to maintain optimal insulation performance.

- Perform routine maintenance and repairs on furnaces and other equipment used in insulation production.

- Repair and replace refractory linings in furnaces and other high-temperature equipment.

- Adhere to all safety regulations and guidelines to ensure a safe and productive work environment.

Frequently Asked Questions (FAQ’s) For Cupola Operator, Insulation

What are the key skills required to be a successful Cupola Operator?

Cupola Operators should have a strong understanding of cupola operation, insulation materials, and safety protocols. They should also be skilled in installing, repairing, and removing insulation, as well as maintaining and repairing furnaces and other equipment.

What are the typical working conditions for a Cupola Operator?

Cupola Operators typically work in industrial settings, such as factories or manufacturing plants. They may be exposed to heat, noise, and dust, and may work in confined spaces. They must also be able to work independently and as part of a team.

What are the career prospects for Cupola Operators?

Cupola Operators with experience and expertise can advance to supervisory or management positions. They may also specialize in a particular type of insulation or equipment, or work in a specific industry, such as power generation or petrochemicals.

What are the educational requirements for a Cupola Operator?

Most Cupola Operators have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in industrial maintenance or a related field.

What are the safety precautions that Cupola Operators must follow?

Cupola Operators must follow all safety regulations and guidelines, including wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators. They must also be aware of the hazards associated with working with molten metal and other hazardous materials.

What are the typical challenges faced by Cupola Operators?

Cupola Operators may face challenges such as working in extreme heat, noise, or dust. They may also work in confined spaces or with hazardous materials. They must be able to troubleshoot problems and make repairs quickly and efficiently.

What are the key responsibilities of a Cupola Operator?

Cupola Operators are responsible for operating and maintaining cupola furnaces, installing and repairing insulation, handling and storing insulation materials, removing and replacing old or damaged insulation, performing routine maintenance and repairs on furnaces and other equipment, and repairing and replacing refractory linings in furnaces and other high-temperature equipment.

What are the key skills required to be a successful Cupola Operator?

Cupola Operators should have a strong understanding of cupola operation, insulation materials, and safety protocols. They should also be skilled in installing, repairing, and removing insulation, as well as maintaining and repairing furnaces and other equipment.