Are you a seasoned Pulp Cooker seeking a new career path? Discover our professionally built Pulp Cooker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

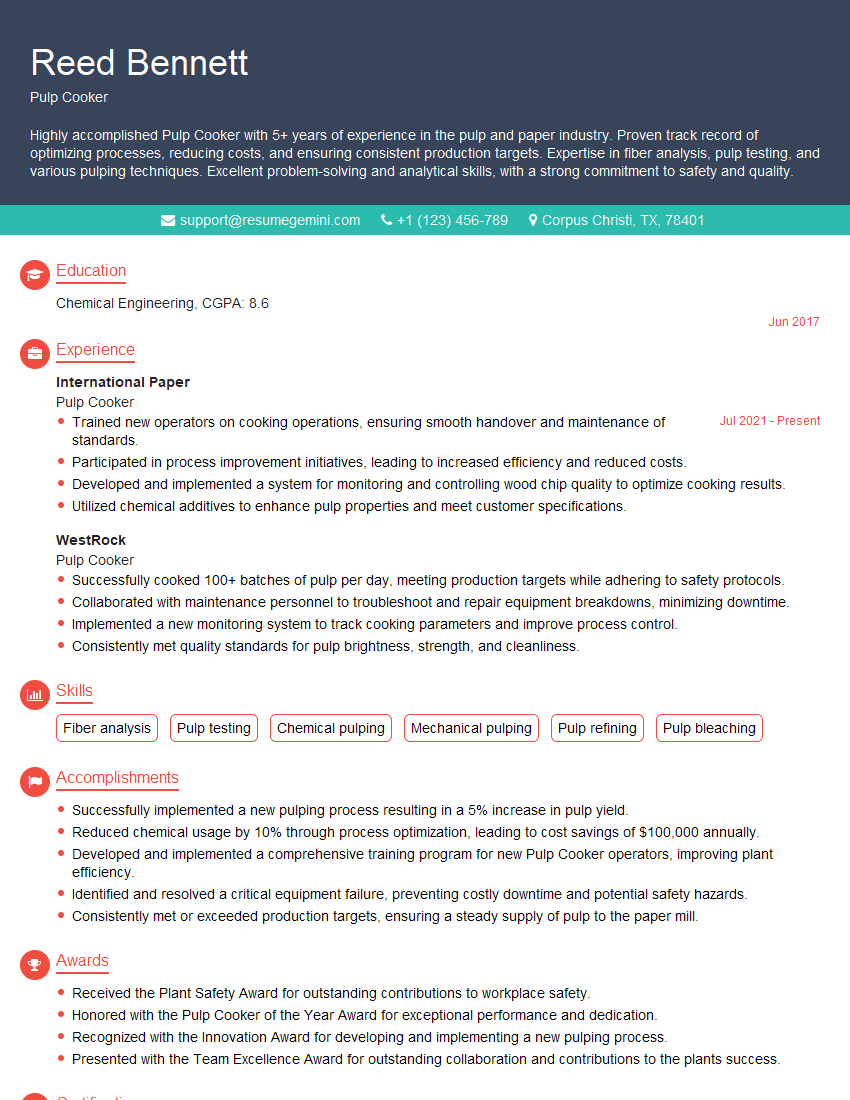

Reed Bennett

Pulp Cooker

Summary

Highly accomplished Pulp Cooker with 5+ years of experience in the pulp and paper industry. Proven track record of optimizing processes, reducing costs, and ensuring consistent production targets. Expertise in fiber analysis, pulp testing, and various pulping techniques. Excellent problem-solving and analytical skills, with a strong commitment to safety and quality.

Education

Chemical Engineering

June 2017

Skills

- Fiber analysis

- Pulp testing

- Chemical pulping

- Mechanical pulping

- Pulp refining

- Pulp bleaching

Work Experience

Pulp Cooker

- Trained new operators on cooking operations, ensuring smooth handover and maintenance of standards.

- Participated in process improvement initiatives, leading to increased efficiency and reduced costs.

- Developed and implemented a system for monitoring and controlling wood chip quality to optimize cooking results.

- Utilized chemical additives to enhance pulp properties and meet customer specifications.

Pulp Cooker

- Successfully cooked 100+ batches of pulp per day, meeting production targets while adhering to safety protocols.

- Collaborated with maintenance personnel to troubleshoot and repair equipment breakdowns, minimizing downtime.

- Implemented a new monitoring system to track cooking parameters and improve process control.

- Consistently met quality standards for pulp brightness, strength, and cleanliness.

Accomplishments

- Successfully implemented a new pulping process resulting in a 5% increase in pulp yield.

- Reduced chemical usage by 10% through process optimization, leading to cost savings of $100,000 annually.

- Developed and implemented a comprehensive training program for new Pulp Cooker operators, improving plant efficiency.

- Identified and resolved a critical equipment failure, preventing costly downtime and potential safety hazards.

- Consistently met or exceeded production targets, ensuring a steady supply of pulp to the paper mill.

Awards

- Received the Plant Safety Award for outstanding contributions to workplace safety.

- Honored with the Pulp Cooker of the Year Award for exceptional performance and dedication.

- Recognized with the Innovation Award for developing and implementing a new pulping process.

- Presented with the Team Excellence Award for outstanding collaboration and contributions to the plants success.

Certificates

- Certified Pulp Maker

- Certified Pulp and Paper Technologist

- Certified Pulp and Paper Safety Manager

- Certified Pulp and Paper Quality Manager

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pulp Cooker

- Highlight your technical expertise in pulp cooking processes, including fiber analysis, pulp testing, and pulping techniques.

- Quantify your accomplishments with specific metrics, such as increased pulp yield, reduced chemical usage, or improved production efficiency.

- Emphasize your problem-solving and analytical skills, providing examples of how you identified and resolved process issues.

- Demonstrate your commitment to safety by mentioning your adherence to all safety protocols and regulations.

Essential Experience Highlights for a Strong Pulp Cooker Resume

- Operate and monitor pulp cooking processes to ensure efficient and consistent production of pulp

- Analyze pulp samples to determine fiber characteristics, chemical composition, and quality

- Monitor and control chemical usage, temperature, and other process parameters to optimize pulp yield and quality

- Troubleshoot and resolve equipment malfunctions and process issues to minimize downtime and maintain production efficiency

- Develop and implement training programs for new Pulp Cooker operators to improve operational skills and safety

- Collaborate with other departments to ensure a smooth flow of production and meet customer requirements

- Adhere to all safety protocols and regulations to maintain a safe and healthy work environment

Frequently Asked Questions (FAQ’s) For Pulp Cooker

What is the role of a Pulp Cooker?

A Pulp Cooker is responsible for operating and monitoring pulp cooking processes to produce pulp for papermaking. They analyze pulp samples, control process parameters, troubleshoot equipment malfunctions, and ensure the efficient and consistent production of pulp.

What are the key skills required for a Pulp Cooker?

Key skills for a Pulp Cooker include fiber analysis, pulp testing, chemical pulping, mechanical pulping, pulp refining, and pulp bleaching. They also need strong problem-solving, analytical, and communication skills.

What is the educational background required for a Pulp Cooker?

Pulp Cookers typically have a degree in Chemical Engineering or a related field.

What are the career prospects for a Pulp Cooker?

Pulp Cookers can advance to positions such as Pulp Mill Supervisor, Production Manager, or Quality Control Manager. They may also specialize in specific areas of pulping or pursue further education in related fields.

What is the work environment of a Pulp Cooker?

Pulp Cookers typically work in pulp and paper mills, which can be noisy and have strong odors. They may work shifts and be required to work in various weather conditions.

What are the safety precautions that a Pulp Cooker must follow?

Pulp Cookers must adhere to all safety protocols and regulations, including wearing appropriate personal protective equipment, following safe operating procedures, and being aware of potential hazards.