Are you a seasoned Spray Drier Operator seeking a new career path? Discover our professionally built Spray Drier Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

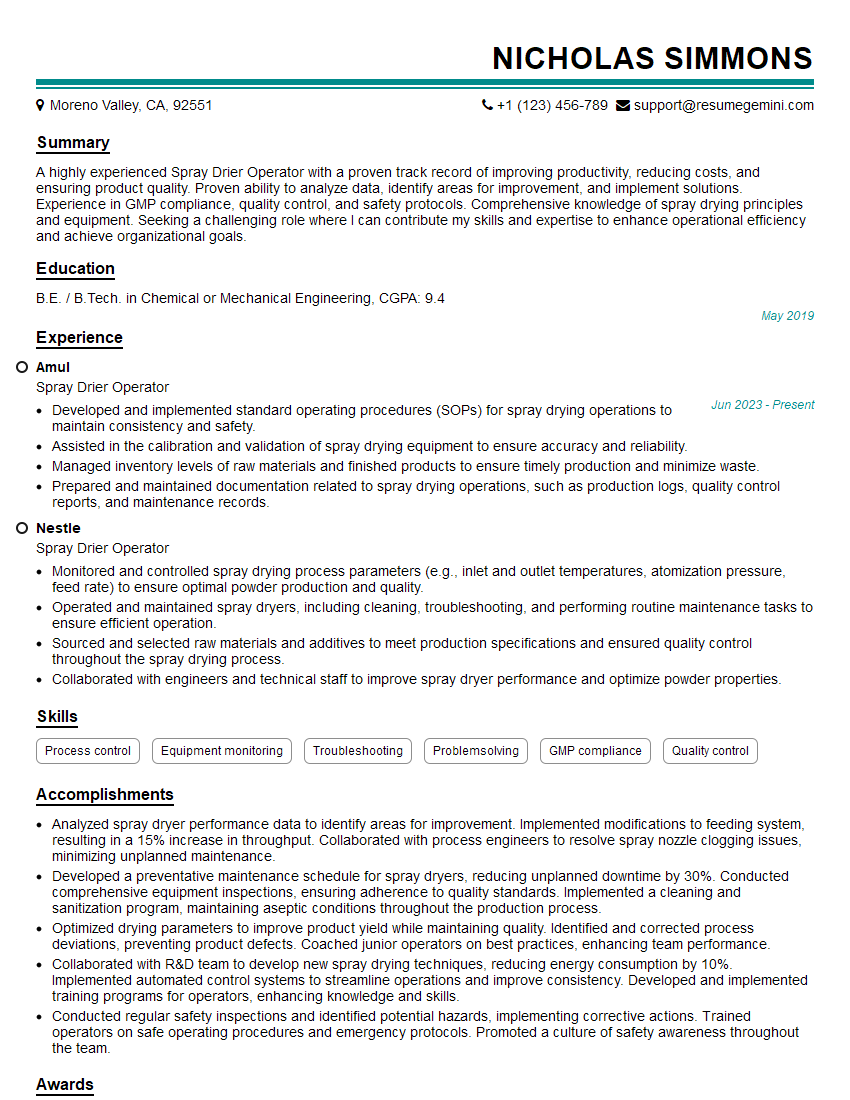

Nicholas Simmons

Spray Drier Operator

Summary

A highly experienced Spray Drier Operator with a proven track record of improving productivity, reducing costs, and ensuring product quality. Proven ability to analyze data, identify areas for improvement, and implement solutions. Experience in GMP compliance, quality control, and safety protocols. Comprehensive knowledge of spray drying principles and equipment. Seeking a challenging role where I can contribute my skills and expertise to enhance operational efficiency and achieve organizational goals.

Education

B.E. / B.Tech. in Chemical or Mechanical Engineering

May 2019

Skills

- Process control

- Equipment monitoring

- Troubleshooting

- Problemsolving

- GMP compliance

- Quality control

Work Experience

Spray Drier Operator

- Developed and implemented standard operating procedures (SOPs) for spray drying operations to maintain consistency and safety.

- Assisted in the calibration and validation of spray drying equipment to ensure accuracy and reliability.

- Managed inventory levels of raw materials and finished products to ensure timely production and minimize waste.

- Prepared and maintained documentation related to spray drying operations, such as production logs, quality control reports, and maintenance records.

Spray Drier Operator

- Monitored and controlled spray drying process parameters (e.g., inlet and outlet temperatures, atomization pressure, feed rate) to ensure optimal powder production and quality.

- Operated and maintained spray dryers, including cleaning, troubleshooting, and performing routine maintenance tasks to ensure efficient operation.

- Sourced and selected raw materials and additives to meet production specifications and ensured quality control throughout the spray drying process.

- Collaborated with engineers and technical staff to improve spray dryer performance and optimize powder properties.

Accomplishments

- Analyzed spray dryer performance data to identify areas for improvement. Implemented modifications to feeding system, resulting in a 15% increase in throughput. Collaborated with process engineers to resolve spray nozzle clogging issues, minimizing unplanned maintenance.

- Developed a preventative maintenance schedule for spray dryers, reducing unplanned downtime by 30%. Conducted comprehensive equipment inspections, ensuring adherence to quality standards. Implemented a cleaning and sanitization program, maintaining aseptic conditions throughout the production process.

- Optimized drying parameters to improve product yield while maintaining quality. Identified and corrected process deviations, preventing product defects. Coached junior operators on best practices, enhancing team performance.

- Collaborated with R&D team to develop new spray drying techniques, reducing energy consumption by 10%. Implemented automated control systems to streamline operations and improve consistency. Developed and implemented training programs for operators, enhancing knowledge and skills.

- Conducted regular safety inspections and identified potential hazards, implementing corrective actions. Trained operators on safe operating procedures and emergency protocols. Promoted a culture of safety awareness throughout the team.

Awards

- Recognized for optimizing spray dryer operations, reducing production time by 25%

- Awarded for maintaining equipment within stringent GMP standards, ensuring product integrity

- Recognized for exceeding production targets consistently, achieving 105% of expected output

- Awarded for outstanding contributions to process optimization, leading to reduced costs and improved efficiency

Certificates

- Certified Spray Dryer Operator (CSDO)

- ISO 90012015

- GMP

- HACCP

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Spray Drier Operator

Highlight your technical expertise:

Emphasize your knowledge of spray drying principles, equipment, and process control systems.Quantify your accomplishments:

Provide specific examples of improvements you have made, such as increasing throughput, reducing downtime, or enhancing product quality.Showcase your problem-solving skills:

Describe how you have identified and resolved technical issues or operational challenges.Emphasize your safety and compliance knowledge:

Highlight your understanding of GMP regulations and safety protocols, as well as your experience in maintaining aseptic conditions.

Essential Experience Highlights for a Strong Spray Drier Operator Resume

- Monitored and controlled spray dryer operations to ensure optimal performance and product quality.

- Analyzed production data and implemented process improvements to enhance efficiency and yield.

- Troubleshooted and resolved equipment malfunctions, minimizing downtime and production losses.

- Maintained a clean and sanitized work environment to comply with GMP standards.

- Trained and supervised junior operators, ensuring adherence to safety and operational procedures.

- Collaborated with engineers and quality control personnel to resolve technical issues and optimize spray drying processes.

- Developed and implemented preventative maintenance plans to minimize unplanned downtime and extend equipment lifespan.

Frequently Asked Questions (FAQ’s) For Spray Drier Operator

What are the key responsibilities of a Spray Drier Operator?

The key responsibilities of a Spray Drier Operator include monitoring and controlling spray dryer operations, analyzing production data, troubleshooting equipment malfunctions, maintaining a clean and sanitized work environment, training and supervising junior operators, collaborating with engineers and quality control personnel, and developing and implementing preventative maintenance plans.

What skills are required to be a successful Spray Drier Operator?

To be a successful Spray Drier Operator, you need to have a strong understanding of spray drying principles, equipment, and process control systems. You should also be able to analyze data, troubleshoot problems, and implement solutions. Additionally, you should be familiar with GMP regulations and safety protocols, and have experience in maintaining aseptic conditions.

What is the career path for a Spray Drier Operator?

The career path for a Spray Drier Operator can vary depending on your experience and qualifications. With additional experience and training, you can advance to roles such as Spray Drying Supervisor, Process Engineer, or Quality Control Manager.

What is the job outlook for Spray Drier Operators?

The job outlook for Spray Drier Operators is expected to be good in the coming years. As the demand for spray-dried products continues to grow, so will the need for qualified operators.

What is the average salary for a Spray Drier Operator?

The average salary for a Spray Drier Operator can vary depending on your experience, qualifications, and location. According to Indeed, the average salary for a Spray Drier Operator in the United States is around $25,000 per year.

What are the benefits of working as a Spray Drier Operator?

The benefits of working as a Spray Drier Operator can include a competitive salary, job security, and the opportunity to work in a fast-paced and challenging environment.