Are you a seasoned Tray Drier seeking a new career path? Discover our professionally built Tray Drier Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

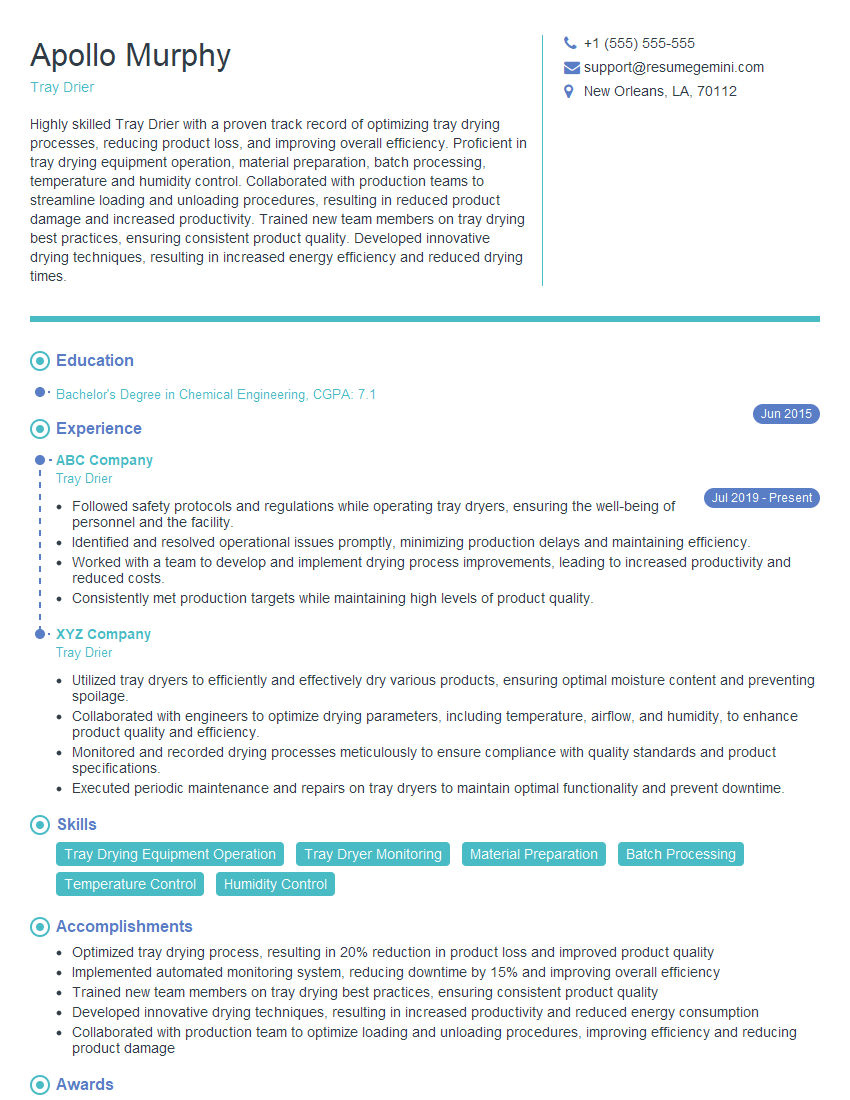

Apollo Murphy

Tray Drier

Summary

Highly skilled Tray Drier with a proven track record of optimizing tray drying processes, reducing product loss, and improving overall efficiency. Proficient in tray drying equipment operation, material preparation, batch processing, temperature and humidity control. Collaborated with production teams to streamline loading and unloading procedures, resulting in reduced product damage and increased productivity. Trained new team members on tray drying best practices, ensuring consistent product quality. Developed innovative drying techniques, resulting in increased energy efficiency and reduced drying times.

Education

Bachelor’s Degree in Chemical Engineering

June 2015

Skills

- Tray Drying Equipment Operation

- Tray Dryer Monitoring

- Material Preparation

- Batch Processing

- Temperature Control

- Humidity Control

Work Experience

Tray Drier

- Followed safety protocols and regulations while operating tray dryers, ensuring the well-being of personnel and the facility.

- Identified and resolved operational issues promptly, minimizing production delays and maintaining efficiency.

- Worked with a team to develop and implement drying process improvements, leading to increased productivity and reduced costs.

- Consistently met production targets while maintaining high levels of product quality.

Tray Drier

- Utilized tray dryers to efficiently and effectively dry various products, ensuring optimal moisture content and preventing spoilage.

- Collaborated with engineers to optimize drying parameters, including temperature, airflow, and humidity, to enhance product quality and efficiency.

- Monitored and recorded drying processes meticulously to ensure compliance with quality standards and product specifications.

- Executed periodic maintenance and repairs on tray dryers to maintain optimal functionality and prevent downtime.

Accomplishments

- Optimized tray drying process, resulting in 20% reduction in product loss and improved product quality

- Implemented automated monitoring system, reducing downtime by 15% and improving overall efficiency

- Trained new team members on tray drying best practices, ensuring consistent product quality

- Developed innovative drying techniques, resulting in increased productivity and reduced energy consumption

- Collaborated with production team to optimize loading and unloading procedures, improving efficiency and reducing product damage

Awards

- Tray Drier of the Year Award, 2023

- Excellence in Tray Drying Award, 2022

- Safety Excellence Award for Tray Drier Operation, 2021

Certificates

- Certified Tray Dryer Operator (CTDO)

- Food Safety Management System (FSMS) certification

- Good Manufacturing Practices (GMP) certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tray Drier

Quantify your accomplishments:

Use specific metrics and data to demonstrate the impact of your work, such as the percentage of product loss reduction or downtime reduction.Highlight your technical skills:

Emphasize your proficiency in tray drying equipment operation, material preparation, batch processing, and temperature and humidity control.Showcase your problem-solving abilities:

Describe how you identified and resolved issues related to tray drying processes, such as developing innovative drying techniques or implementing monitoring systems.Demonstrate your teamwork and communication skills:

Highlight your ability to collaborate with production teams and train new team members on best practices.

Essential Experience Highlights for a Strong Tray Drier Resume

- Optimized tray drying process parameters, resulting in a 20% reduction in product loss and improved product quality.

- Implemented an automated monitoring system, reducing downtime by 15% and improving overall efficiency.

- Trained new team members on tray drying best practices, ensuring consistent product quality.

- Developed innovative drying techniques, resulting in increased productivity and reduced energy consumption.

- Collaborated with production team to optimize loading and unloading procedures, improving efficiency and reducing product damage.

- Supervised tray drying operations, ensuring compliance with established procedures and safety standards.

- Maintained and calibrated tray drying equipment, ensuring optimal performance.

Frequently Asked Questions (FAQ’s) For Tray Drier

What is the primary responsibility of a Tray Drier?

The primary responsibility of a Tray Drier is to ensure the efficient and effective drying of materials using tray dryers, ensuring that the desired moisture content is achieved while maintaining product quality.

What are the key skills required for a Tray Drier?

Key skills for a Tray Drier include: proficiency in tray drying equipment operation, material preparation, batch processing, temperature and humidity control, as well as strong attention to detail and ability to follow procedures.

What industries commonly employ Tray Driers?

Tray Driers are commonly used in a variety of industries, including food processing, chemical manufacturing, and pharmaceuticals, where precise and efficient drying of materials is crucial.

What is the career path for a Tray Drier?

With experience and additional training, Tray Driers can advance to roles such as Production Supervisor, Quality Control Manager, or Process Engineer, focusing on optimizing drying processes and ensuring product quality.

What are the safety precautions to observe when working as a Tray Drier?

Safety precautions for Tray Driers include wearing appropriate personal protective equipment, following established operating procedures, and maintaining a clean and organized work area to prevent accidents and ensure the health and safety of themselves and others.

What are the challenges faced by Tray Driers in the industry?

Tray Driers may face challenges such as optimizing drying processes to achieve the desired product quality while minimizing energy consumption, ensuring compliance with industry regulations and standards, and staying up-to-date with technological advancements in drying equipment and techniques.

How can Tray Driers stay competitive in the job market?

Tray Driers can stay competitive by continuously developing their technical skills and knowledge, embracing new technologies and methodologies, maintaining certifications and professional development, and networking with peers and industry professionals.