Are you a seasoned Tunnel Kiln Operator seeking a new career path? Discover our professionally built Tunnel Kiln Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

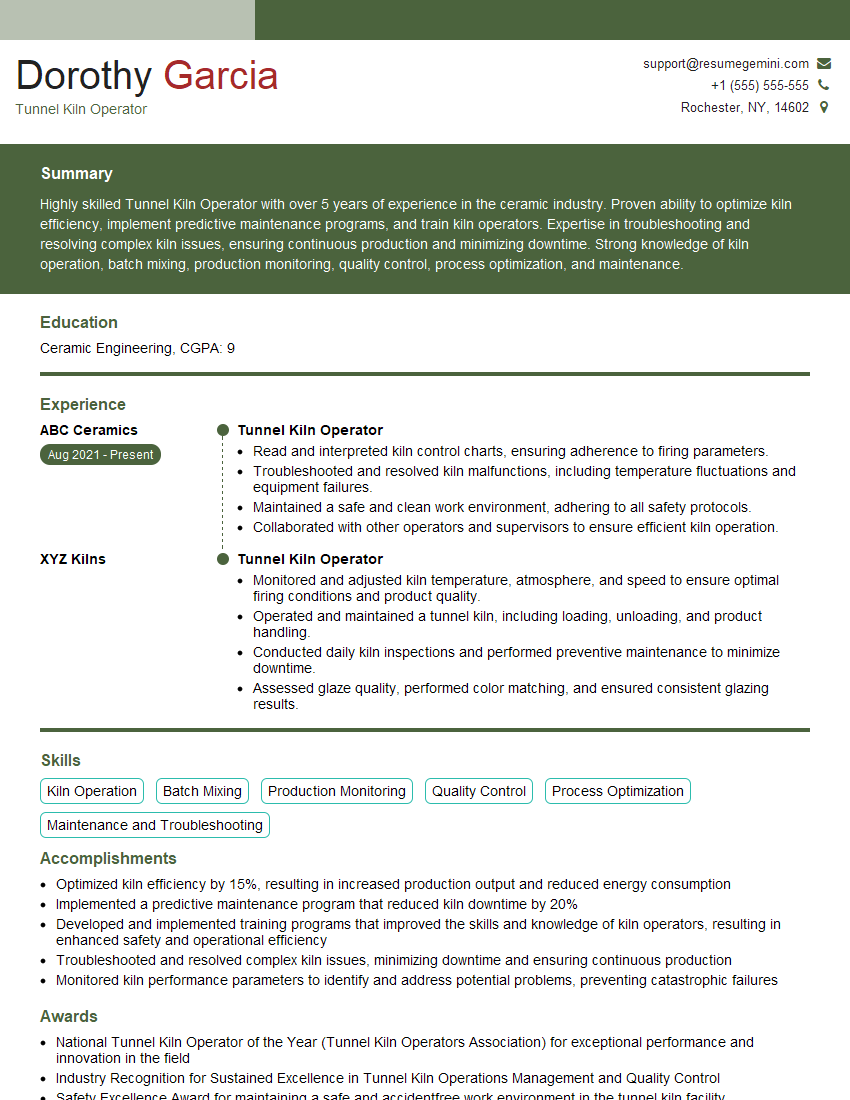

Dorothy Garcia

Tunnel Kiln Operator

Summary

Highly skilled Tunnel Kiln Operator with over 5 years of experience in the ceramic industry. Proven ability to optimize kiln efficiency, implement predictive maintenance programs, and train kiln operators. Expertise in troubleshooting and resolving complex kiln issues, ensuring continuous production and minimizing downtime. Strong knowledge of kiln operation, batch mixing, production monitoring, quality control, process optimization, and maintenance.

Education

Ceramic Engineering

July 2017

Skills

- Kiln Operation

- Batch Mixing

- Production Monitoring

- Quality Control

- Process Optimization

- Maintenance and Troubleshooting

Work Experience

Tunnel Kiln Operator

- Read and interpreted kiln control charts, ensuring adherence to firing parameters.

- Troubleshooted and resolved kiln malfunctions, including temperature fluctuations and equipment failures.

- Maintained a safe and clean work environment, adhering to all safety protocols.

- Collaborated with other operators and supervisors to ensure efficient kiln operation.

Tunnel Kiln Operator

- Monitored and adjusted kiln temperature, atmosphere, and speed to ensure optimal firing conditions and product quality.

- Operated and maintained a tunnel kiln, including loading, unloading, and product handling.

- Conducted daily kiln inspections and performed preventive maintenance to minimize downtime.

- Assessed glaze quality, performed color matching, and ensured consistent glazing results.

Accomplishments

- Optimized kiln efficiency by 15%, resulting in increased production output and reduced energy consumption

- Implemented a predictive maintenance program that reduced kiln downtime by 20%

- Developed and implemented training programs that improved the skills and knowledge of kiln operators, resulting in enhanced safety and operational efficiency

- Troubleshooted and resolved complex kiln issues, minimizing downtime and ensuring continuous production

- Monitored kiln performance parameters to identify and address potential problems, preventing catastrophic failures

Awards

- National Tunnel Kiln Operator of the Year (Tunnel Kiln Operators Association) for exceptional performance and innovation in the field

- Industry Recognition for Sustained Excellence in Tunnel Kiln Operations Management and Quality Control

- Safety Excellence Award for maintaining a safe and accidentfree work environment in the tunnel kiln facility

- Certificate of Excellence for Innovation in Tunnel Kiln Design and Operation

Certificates

- Certified Kiln Operator

- Certified Ceramic Engineer

- Certified Six Sigma Green Belt

- Certified Lean Manufacturing Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tunnel Kiln Operator

- Highlight your experience and skills in optimizing kiln efficiency and reducing downtime.

- Quantify your accomplishments whenever possible, using specific metrics and data points.

- Emphasize your ability to troubleshoot and resolve complex kiln issues.

- Showcase your knowledge of kiln operation, batch mixing, production monitoring, and quality control.

Essential Experience Highlights for a Strong Tunnel Kiln Operator Resume

- Optimized kiln efficiency by 15%, resulting in increased production output and reduced energy consumption.

- Implemented a predictive maintenance program that reduced kiln downtime by 20%.

- Developed and implemented training programs that improved the skills and knowledge of kiln operators, resulting in enhanced safety and operational efficiency.

- Troubleshooted and resolved complex kiln issues, minimizing downtime and ensuring continuous production.

- Monitored kiln performance parameters to identify and address potential problems, preventing catastrophic failures.

- Supervised a team of kiln operators, ensuring adherence to safety protocols and operational procedures.

Frequently Asked Questions (FAQ’s) For Tunnel Kiln Operator

What are the primary responsibilities of a Tunnel Kiln Operator?

Tunnel Kiln Operators are responsible for operating, monitoring, and maintaining tunnel kilns, which are used to fire ceramic products. They ensure that the kiln operates efficiently and safely, and that the products are fired to the correct specifications.

What skills are required to be a successful Tunnel Kiln Operator?

Successful Tunnel Kiln Operators typically have a strong understanding of kiln operation, batch mixing, production monitoring, quality control, process optimization, and maintenance. They are also skilled in troubleshooting and resolving kiln issues.

What are the career prospects for Tunnel Kiln Operators?

Tunnel Kiln Operators can advance to supervisory roles, such as Kiln Supervisor or Production Manager. They may also move into technical roles, such as Kiln Engineer or Process Engineer.

What is the average salary for a Tunnel Kiln Operator?

The average salary for a Tunnel Kiln Operator in the United States is around $50,000 per year.

What is the job outlook for Tunnel Kiln Operators?

The job outlook for Tunnel Kiln Operators is expected to be good in the coming years, as the demand for ceramic products continues to grow.

What are the key challenges faced by Tunnel Kiln Operators?

Tunnel Kiln Operators face a number of challenges, including the need to maintain a consistent firing temperature, prevent product defects, and troubleshoot kiln issues.