Are you a seasoned Winding Inspector seeking a new career path? Discover our professionally built Winding Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

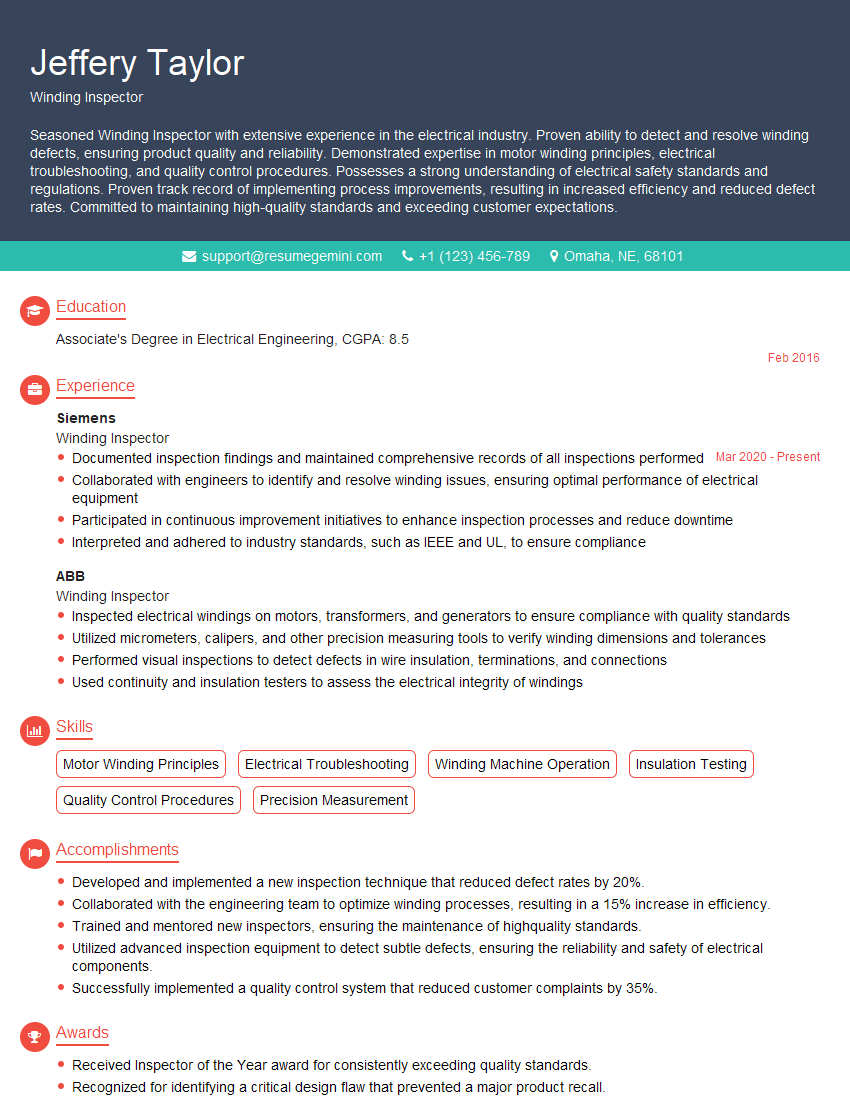

Jeffery Taylor

Winding Inspector

Summary

Seasoned Winding Inspector with extensive experience in the electrical industry. Proven ability to detect and resolve winding defects, ensuring product quality and reliability. Demonstrated expertise in motor winding principles, electrical troubleshooting, and quality control procedures. Possesses a strong understanding of electrical safety standards and regulations. Proven track record of implementing process improvements, resulting in increased efficiency and reduced defect rates. Committed to maintaining high-quality standards and exceeding customer expectations.

Education

Associate’s Degree in Electrical Engineering

February 2016

Skills

- Motor Winding Principles

- Electrical Troubleshooting

- Winding Machine Operation

- Insulation Testing

- Quality Control Procedures

- Precision Measurement

Work Experience

Winding Inspector

- Documented inspection findings and maintained comprehensive records of all inspections performed

- Collaborated with engineers to identify and resolve winding issues, ensuring optimal performance of electrical equipment

- Participated in continuous improvement initiatives to enhance inspection processes and reduce downtime

- Interpreted and adhered to industry standards, such as IEEE and UL, to ensure compliance

Winding Inspector

- Inspected electrical windings on motors, transformers, and generators to ensure compliance with quality standards

- Utilized micrometers, calipers, and other precision measuring tools to verify winding dimensions and tolerances

- Performed visual inspections to detect defects in wire insulation, terminations, and connections

- Used continuity and insulation testers to assess the electrical integrity of windings

Accomplishments

- Developed and implemented a new inspection technique that reduced defect rates by 20%.

- Collaborated with the engineering team to optimize winding processes, resulting in a 15% increase in efficiency.

- Trained and mentored new inspectors, ensuring the maintenance of highquality standards.

- Utilized advanced inspection equipment to detect subtle defects, ensuring the reliability and safety of electrical components.

- Successfully implemented a quality control system that reduced customer complaints by 35%.

Awards

- Received Inspector of the Year award for consistently exceeding quality standards.

- Recognized for identifying a critical design flaw that prevented a major product recall.

- Received a Zero Defect award for maintaining an exceptional quality record for over 12 consecutive months.

- Honored with a Safety Excellence award for adhering to strict safety protocols and maintaining a hazardfree work environment.

Certificates

- Certified Winding Inspector (CWI)

- International Electrotechnical Commission (IEC) Compliance

- Occupational Safety and Health Administration (OSHA) Certification

- Institute of Electrical and Electronics Engineers (IEEE) Membership

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Winding Inspector

- Showcase your expertise in motor winding principles and electrical troubleshooting techniques.

- Highlight your experience in using advanced inspection equipment and implementing quality control procedures.

- Quantify your accomplishments with specific metrics, such as defect reduction percentages and efficiency improvements.

- Emphasize your ability to collaborate with cross-functional teams and contribute to process optimization.

- Include keywords relevant to the electrical industry, such as motor winding, electrical troubleshooting, quality control, and electrical safety.

Essential Experience Highlights for a Strong Winding Inspector Resume

- Inspect electrical windings for defects using advanced inspection equipment and techniques.

- Troubleshoot and resolve electrical winding issues to ensure optimal performance and safety.

- Adhere to established quality control procedures and specifications to maintain product quality.

- Collaborate with engineering and production teams to optimize winding processes and improve efficiency.

- Train and mentor new inspectors to ensure the maintenance of high-quality standards.

- Implement and maintain a quality control system to minimize defects and customer complaints.

Frequently Asked Questions (FAQ’s) For Winding Inspector

What is the primary role of a Winding Inspector?

A Winding Inspector is responsible for ensuring the quality and reliability of electrical windings by detecting and resolving defects, adhering to quality control procedures, and collaborating with engineering and production teams to optimize winding processes.

What are the essential skills required for a Winding Inspector?

Essential skills include motor winding principles, electrical troubleshooting, winding machine operation, insulation testing, quality control procedures, and precision measurement.

What are the career prospects for a Winding Inspector?

With experience and additional training, Winding Inspectors can advance to roles such as Quality Control Manager, Manufacturing Supervisor, or Electrical Engineer.

What are the challenges faced by Winding Inspectors?

Challenges include working with delicate electrical components, adhering to strict quality standards, and staying up-to-date with industry advancements.

What is the work environment like for a Winding Inspector?

Winding Inspectors typically work in manufacturing facilities or electrical repair shops, often in a team environment. They may be exposed to noise, dust, and chemicals, so safety precautions are essential.