Are you a seasoned Recoating Machine Operator seeking a new career path? Discover our professionally built Recoating Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

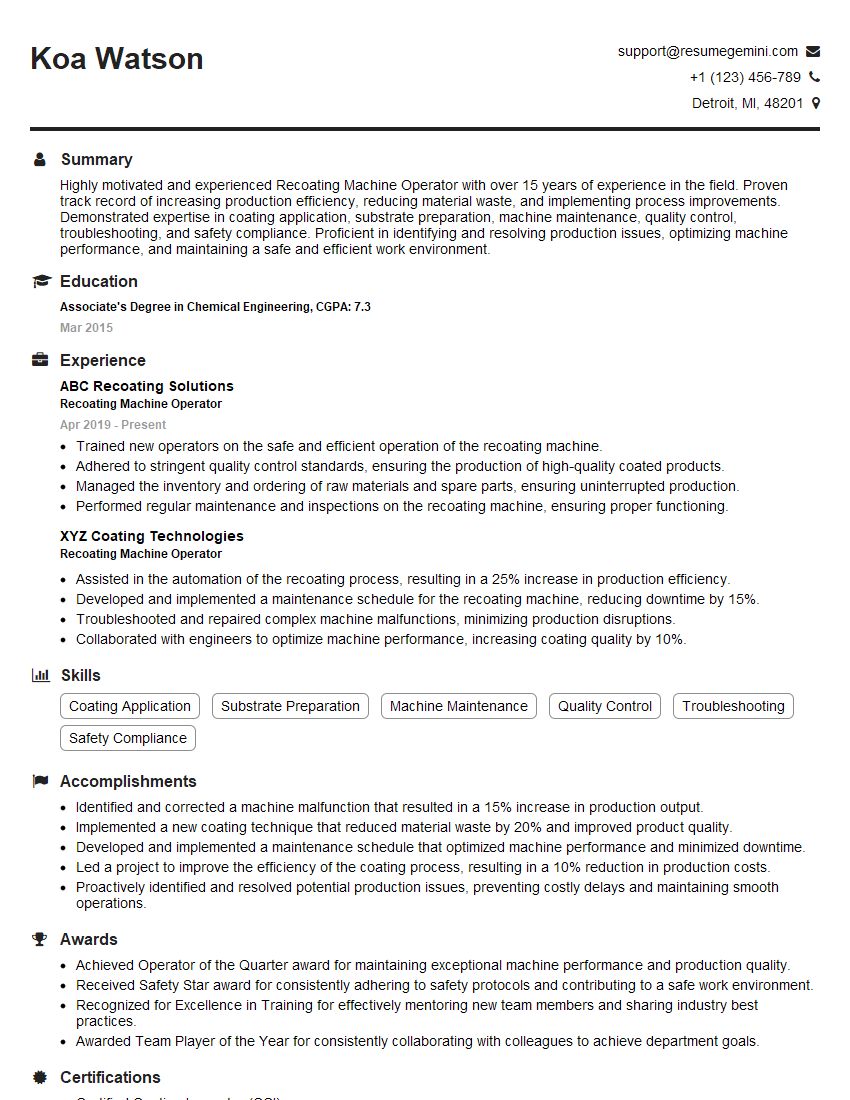

Koa Watson

Recoating Machine Operator

Summary

Highly motivated and experienced Recoating Machine Operator with over 15 years of experience in the field. Proven track record of increasing production efficiency, reducing material waste, and implementing process improvements. Demonstrated expertise in coating application, substrate preparation, machine maintenance, quality control, troubleshooting, and safety compliance. Proficient in identifying and resolving production issues, optimizing machine performance, and maintaining a safe and efficient work environment.

Education

Associate’s Degree in Chemical Engineering

March 2015

Skills

- Coating Application

- Substrate Preparation

- Machine Maintenance

- Quality Control

- Troubleshooting

- Safety Compliance

Work Experience

Recoating Machine Operator

- Trained new operators on the safe and efficient operation of the recoating machine.

- Adhered to stringent quality control standards, ensuring the production of high-quality coated products.

- Managed the inventory and ordering of raw materials and spare parts, ensuring uninterrupted production.

- Performed regular maintenance and inspections on the recoating machine, ensuring proper functioning.

Recoating Machine Operator

- Assisted in the automation of the recoating process, resulting in a 25% increase in production efficiency.

- Developed and implemented a maintenance schedule for the recoating machine, reducing downtime by 15%.

- Troubleshooted and repaired complex machine malfunctions, minimizing production disruptions.

- Collaborated with engineers to optimize machine performance, increasing coating quality by 10%.

Accomplishments

- Identified and corrected a machine malfunction that resulted in a 15% increase in production output.

- Implemented a new coating technique that reduced material waste by 20% and improved product quality.

- Developed and implemented a maintenance schedule that optimized machine performance and minimized downtime.

- Led a project to improve the efficiency of the coating process, resulting in a 10% reduction in production costs.

- Proactively identified and resolved potential production issues, preventing costly delays and maintaining smooth operations.

Awards

- Achieved Operator of the Quarter award for maintaining exceptional machine performance and production quality.

- Received Safety Star award for consistently adhering to safety protocols and contributing to a safe work environment.

- Recognized for Excellence in Training for effectively mentoring new team members and sharing industry best practices.

- Awarded Team Player of the Year for consistently collaborating with colleagues to achieve department goals.

Certificates

- Certified Coating Inspector (CCI)

- National Association of Finishing Processes (NAFP) Certificate

- Society for Protective Coatings (SSPC) Journeyman Recoating Machine Operator Certification

- American Coatings Association (ACA) Coating Inspector Level I Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Recoating Machine Operator

- Highlight your technical skills: Mention your proficiency in operating and maintaining coating machines, as well as your knowledge of coating application techniques and quality control procedures.

- Quantify your accomplishments: Use specific numbers and metrics to demonstrate your impact on the organization. For example, mention the percentage increase in production output or the reduction in material waste that you achieved.

- Emphasize your problem-solving abilities: Showcase your ability to troubleshoot and resolve machine malfunctions, as well as your proactive approach to identifying and preventing potential production issues.

- Demonstrate your commitment to safety: Highlight your adherence to safety protocols and your role in maintaining a safe and efficient work environment.

Essential Experience Highlights for a Strong Recoating Machine Operator Resume

- Operate and maintain coating machines to apply protective and decorative coatings to a variety of materials.

- Prepare substrate surfaces by cleaning, sanding, or etching to ensure proper coating adhesion.

- Monitor and adjust machine settings to ensure optimal coating thickness, uniformity, and quality.

- Conduct quality control inspections to ensure that finished products meet specifications and customer requirements.

- Troubleshoot and resolve machine malfunctions, including electrical, mechanical, and software issues.

- Follow safety protocols and maintain a clean and organized work area at all times.

Frequently Asked Questions (FAQ’s) For Recoating Machine Operator

What are the key skills required to be a successful Recoating Machine Operator?

The key skills required to be a successful Recoating Machine Operator include coating application techniques, substrate preparation knowledge, machine maintenance skills, quality control procedures, troubleshooting abilities, and safety compliance.

What are the typical job responsibilities of a Recoating Machine Operator?

The typical job responsibilities of a Recoating Machine Operator include operating and maintaining coating machines, preparing substrate surfaces, monitoring and adjusting machine settings, conducting quality control inspections, troubleshooting and resolving machine malfunctions, and following safety protocols.

What are the qualifications required to become a Recoating Machine Operator?

The qualifications required to become a Recoating Machine Operator typically include a high school diploma or equivalent, and some experience in operating machinery or manufacturing processes. Additional training in coating application or related fields may also be beneficial.

What are the career advancement opportunities for Recoating Machine Operators?

Recoating Machine Operators may advance to positions such as Lead Operator, Supervisor, or Quality Control Manager. With additional training and experience, they may also become involved in research and development of new coating technologies.

What is the job outlook for Recoating Machine Operators?

The job outlook for Recoating Machine Operators is expected to be positive over the next few years. The increasing demand for coated products in various industries, such as automotive, construction, and electronics, is expected to drive job growth.

What are the safety precautions that Recoating Machine Operators should take?

Recoating Machine Operators should wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators, to protect themselves from hazardous materials or fumes. They should also be aware of the potential hazards of working with machinery and follow all safety protocols.

How can I improve my chances of getting a job as a Recoating Machine Operator?

To improve your chances of getting a job as a Recoating Machine Operator, you can obtain formal training or certification in coating application or related fields. You can also gain experience by volunteering or interning at companies that use coating machines. Additionally, you should emphasize your technical skills, problem-solving abilities, and commitment to safety on your resume and cover letter.

What are the typical working conditions for Recoating Machine Operators?

Recoating Machine Operators typically work in manufacturing facilities or workshops. They may work in a variety of environments, including clean rooms, warehouses, or outdoor areas. They may also work on a variety of shifts, including day, evening, or weekend shifts.