Are you a seasoned Production Metal Sprayer seeking a new career path? Discover our professionally built Production Metal Sprayer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

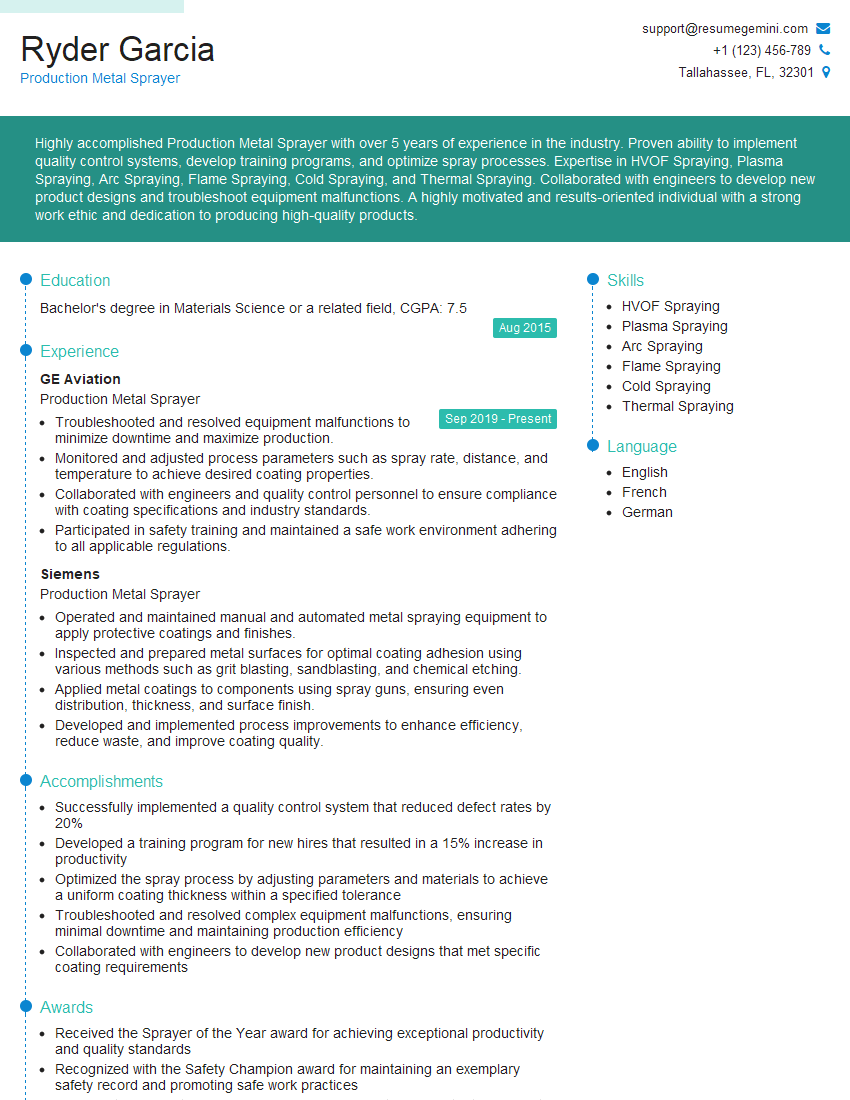

Ryder Garcia

Production Metal Sprayer

Summary

Highly accomplished Production Metal Sprayer with over 5 years of experience in the industry. Proven ability to implement quality control systems, develop training programs, and optimize spray processes. Expertise in HVOF Spraying, Plasma Spraying, Arc Spraying, Flame Spraying, Cold Spraying, and Thermal Spraying. Collaborated with engineers to develop new product designs and troubleshoot equipment malfunctions. A highly motivated and results-oriented individual with a strong work ethic and dedication to producing high-quality products.

Education

Bachelor’s degree in Materials Science or a related field

August 2015

Skills

- HVOF Spraying

- Plasma Spraying

- Arc Spraying

- Flame Spraying

- Cold Spraying

- Thermal Spraying

Work Experience

Production Metal Sprayer

- Troubleshooted and resolved equipment malfunctions to minimize downtime and maximize production.

- Monitored and adjusted process parameters such as spray rate, distance, and temperature to achieve desired coating properties.

- Collaborated with engineers and quality control personnel to ensure compliance with coating specifications and industry standards.

- Participated in safety training and maintained a safe work environment adhering to all applicable regulations.

Production Metal Sprayer

- Operated and maintained manual and automated metal spraying equipment to apply protective coatings and finishes.

- Inspected and prepared metal surfaces for optimal coating adhesion using various methods such as grit blasting, sandblasting, and chemical etching.

- Applied metal coatings to components using spray guns, ensuring even distribution, thickness, and surface finish.

- Developed and implemented process improvements to enhance efficiency, reduce waste, and improve coating quality.

Accomplishments

- Successfully implemented a quality control system that reduced defect rates by 20%

- Developed a training program for new hires that resulted in a 15% increase in productivity

- Optimized the spray process by adjusting parameters and materials to achieve a uniform coating thickness within a specified tolerance

- Troubleshooted and resolved complex equipment malfunctions, ensuring minimal downtime and maintaining production efficiency

- Collaborated with engineers to develop new product designs that met specific coating requirements

Awards

- Received the Sprayer of the Year award for achieving exceptional productivity and quality standards

- Recognized with the Safety Champion award for maintaining an exemplary safety record and promoting safe work practices

- Awarded the Innovation Award for developing a new technique that significantly improved coating efficiency

Certificates

- Certified Thermal Spray Technician (CTST)

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certified Welding Inspector

- American Society for Nondestructive Testing (ASNT) Level II Ultrasonic Testing

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Metal Sprayer

- Highlight your technical skills and experience in different types of metal spraying techniques.

- Quantify your accomplishments and provide specific examples of how you have improved processes or reduced costs.

- Demonstrate your knowledge of quality control and safety procedures.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Production Metal Sprayer Resume

- Implemented a quality control system that reduced defect rates by 20%.

- Developed a training program for new hires that resulted in a 15% increase in productivity.

- Optimized the spray process by adjusting parameters and materials to achieve a uniform coating thickness within a specified tolerance.

- Troubleshooted and resolved complex equipment malfunctions, ensuring minimal downtime and maintaining production efficiency.

- Collaborated with engineers to develop new product designs that met specific coating requirements.

Frequently Asked Questions (FAQ’s) For Production Metal Sprayer

What is the role of a Production Metal Sprayer?

A Production Metal Sprayer is responsible for applying metal coatings to various substrates using specialized spraying techniques. They ensure the quality and uniformity of the coatings and troubleshoot any equipment or process issues.

What are the different types of metal spraying techniques?

There are various metal spraying techniques, including HVOF Spraying, Plasma Spraying, Arc Spraying, Flame Spraying, Cold Spraying, and Thermal Spraying.

What are the key skills required for a Production Metal Sprayer?

Key skills include expertise in metal spraying techniques, knowledge of coating materials and properties, quality control procedures, and troubleshooting abilities.

What industries employ Production Metal Sprayers?

Production Metal Sprayers are employed in industries such as aerospace, automotive, manufacturing, and energy.

How can I become a Production Metal Sprayer?

Typically, a bachelor’s degree in Materials Science or a related field and hands-on training in metal spraying techniques are required.

What is the career outlook for Production Metal Sprayers?

The demand for Production Metal Sprayers is expected to grow due to the increasing use of metal coatings in various industries.