Are you a seasoned Thermal Spray Operator seeking a new career path? Discover our professionally built Thermal Spray Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

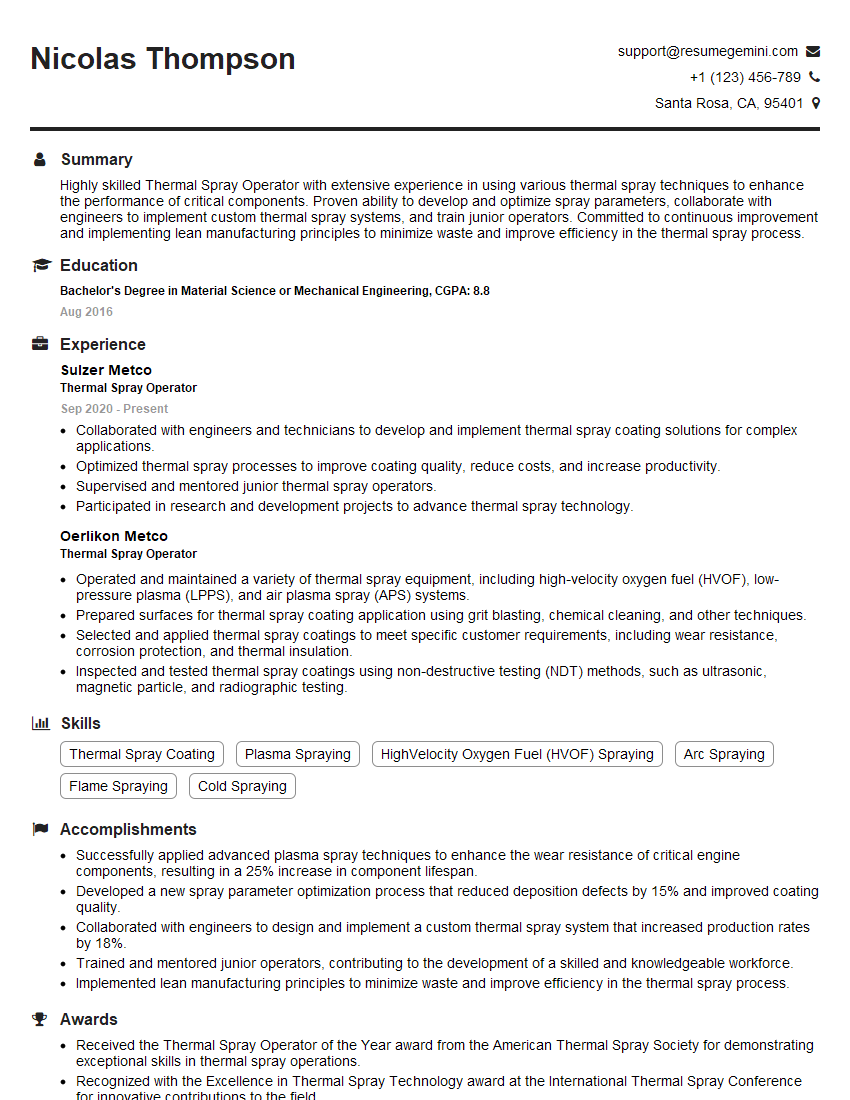

Nicolas Thompson

Thermal Spray Operator

Summary

Highly skilled Thermal Spray Operator with extensive experience in using various thermal spray techniques to enhance the performance of critical components. Proven ability to develop and optimize spray parameters, collaborate with engineers to implement custom thermal spray systems, and train junior operators. Committed to continuous improvement and implementing lean manufacturing principles to minimize waste and improve efficiency in the thermal spray process.

Education

Bachelor’s Degree in Material Science or Mechanical Engineering

August 2016

Skills

- Thermal Spray Coating

- Plasma Spraying

- HighVelocity Oxygen Fuel (HVOF) Spraying

- Arc Spraying

- Flame Spraying

- Cold Spraying

Work Experience

Thermal Spray Operator

- Collaborated with engineers and technicians to develop and implement thermal spray coating solutions for complex applications.

- Optimized thermal spray processes to improve coating quality, reduce costs, and increase productivity.

- Supervised and mentored junior thermal spray operators.

- Participated in research and development projects to advance thermal spray technology.

Thermal Spray Operator

- Operated and maintained a variety of thermal spray equipment, including high-velocity oxygen fuel (HVOF), low-pressure plasma (LPPS), and air plasma spray (APS) systems.

- Prepared surfaces for thermal spray coating application using grit blasting, chemical cleaning, and other techniques.

- Selected and applied thermal spray coatings to meet specific customer requirements, including wear resistance, corrosion protection, and thermal insulation.

- Inspected and tested thermal spray coatings using non-destructive testing (NDT) methods, such as ultrasonic, magnetic particle, and radiographic testing.

Accomplishments

- Successfully applied advanced plasma spray techniques to enhance the wear resistance of critical engine components, resulting in a 25% increase in component lifespan.

- Developed a new spray parameter optimization process that reduced deposition defects by 15% and improved coating quality.

- Collaborated with engineers to design and implement a custom thermal spray system that increased production rates by 18%.

- Trained and mentored junior operators, contributing to the development of a skilled and knowledgeable workforce.

- Implemented lean manufacturing principles to minimize waste and improve efficiency in the thermal spray process.

Awards

- Received the Thermal Spray Operator of the Year award from the American Thermal Spray Society for demonstrating exceptional skills in thermal spray operations.

- Recognized with the Excellence in Thermal Spray Technology award at the International Thermal Spray Conference for innovative contributions to the field.

- Honored with the Safety Excellence Award for maintaining an accidentfree record and implementing innovative safety measures in the thermal spray workplace.

- Awarded the Gold Star Award for consistently meeting and exceeding performance goals in thermal spray operations.

Certificates

- Certified Thermal Spray Technician (CTST)

- Certified Spray Coating Inspector (CSCI)

- ASME Boiler and Pressure Vessel Code Inspector

- AWS Certified Welding Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Thermal Spray Operator

- Highlight your experience with different thermal spray techniques and your ability to optimize spray parameters.

- Showcase your problem-solving skills and ability to collaborate with engineers to improve processes.

- Emphasize your commitment to safety and quality control.

- Quantify your accomplishments whenever possible, using specific metrics such as increased component lifespan or reduced deposition defects.

- Research thermal spray companies and their areas of specialization to tailor your resume to the specific requirements of the position.

Essential Experience Highlights for a Strong Thermal Spray Operator Resume

- Operate and maintain thermal spray equipment, including plasma spray, HVOF spray, arc spray, flame spray, and cold spray systems.

- Develop and optimize spray parameters to ensure high-quality coatings with desired properties, such as wear resistance, corrosion resistance, and thermal insulation.

- Collaborate with engineers to design and implement custom thermal spray systems to meet specific production requirements.

- Train and mentor junior operators on thermal spray techniques and safety procedures.

- Implement lean manufacturing principles to minimize waste and improve efficiency in the thermal spray process.

- Conduct quality control inspections to ensure that thermal spray coatings meet specifications.

- Stay up-to-date on the latest thermal spray technologies and advancements.

Frequently Asked Questions (FAQ’s) For Thermal Spray Operator

What are the different types of thermal spray techniques?

The most common thermal spray techniques include plasma spray, HVOF spray, arc spray, flame spray, and cold spray. Each technique has its own advantages and disadvantages, and the choice of technique depends on the specific application.

What are the key factors to consider when optimizing thermal spray parameters?

The key factors to consider when optimizing thermal spray parameters include the type of coating material, the substrate material, the desired coating properties, and the specific thermal spray equipment being used.

What is the purpose of a thermal spray operator?

A thermal spray operator is responsible for applying thermal spray coatings to a variety of substrates to improve their performance and longevity.

What are the career prospects for a thermal spray operator?

Thermal spray operators are in high demand in a variety of industries, including aerospace, automotive, and manufacturing. With experience, thermal spray operators can advance to supervisory or management positions.

What are the key skills required for a thermal spray operator?

The key skills required for a thermal spray operator include knowledge of thermal spray techniques, experience with thermal spray equipment, and a strong understanding of coating materials and their properties.

What is the typical salary for a thermal spray operator?

The typical salary for a thermal spray operator varies depending on experience, location, and industry. According to Indeed, the average salary for a Thermal Spray Operator in the United States is $68,000 per year.

What are the benefits of using thermal spray coatings?

Thermal spray coatings offer a number of benefits, including improved wear resistance, corrosion resistance, thermal insulation, and electrical conductivity.