Are you a seasoned Undercoater seeking a new career path? Discover our professionally built Undercoater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

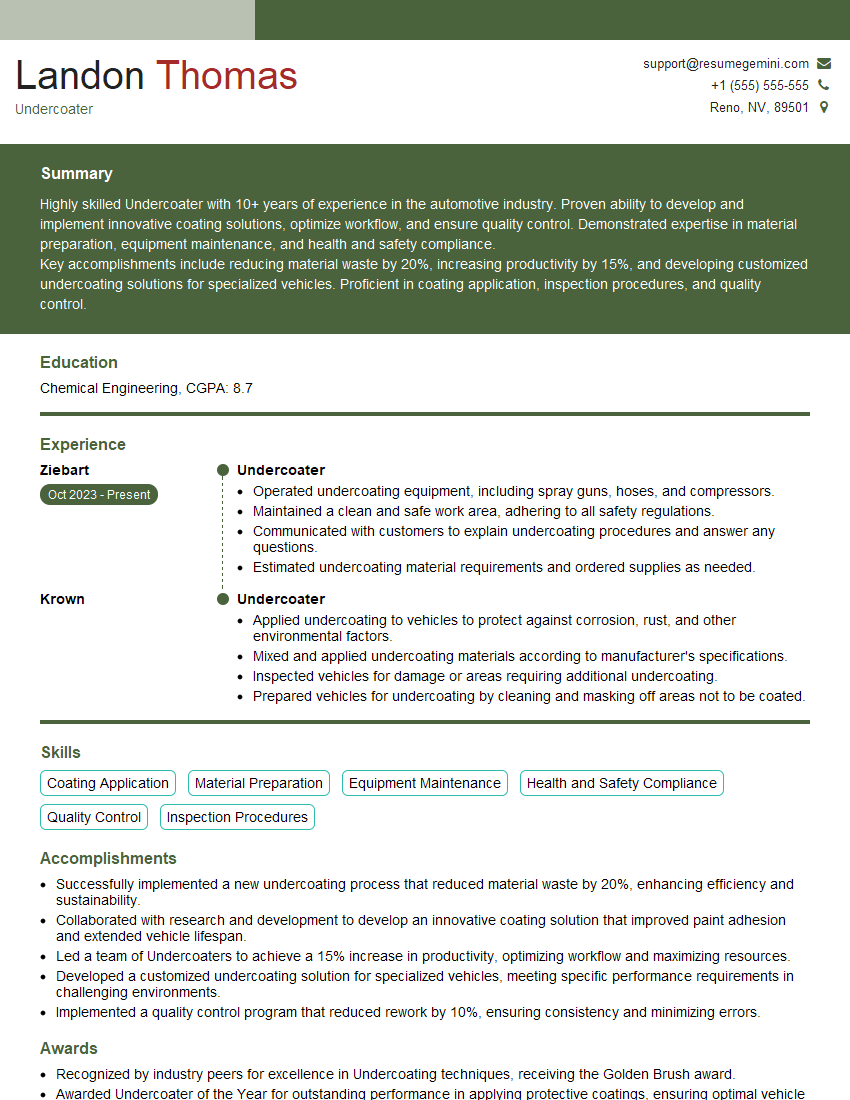

Landon Thomas

Undercoater

Summary

Highly skilled Undercoater with 10+ years of experience in the automotive industry. Proven ability to develop and implement innovative coating solutions, optimize workflow, and ensure quality control. Demonstrated expertise in material preparation, equipment maintenance, and health and safety compliance.

Key accomplishments include reducing material waste by 20%, increasing productivity by 15%, and developing customized undercoating solutions for specialized vehicles. Proficient in coating application, inspection procedures, and quality control.

Education

Chemical Engineering

September 2019

Skills

- Coating Application

- Material Preparation

- Equipment Maintenance

- Health and Safety Compliance

- Quality Control

- Inspection Procedures

Work Experience

Undercoater

- Operated undercoating equipment, including spray guns, hoses, and compressors.

- Maintained a clean and safe work area, adhering to all safety regulations.

- Communicated with customers to explain undercoating procedures and answer any questions.

- Estimated undercoating material requirements and ordered supplies as needed.

Undercoater

- Applied undercoating to vehicles to protect against corrosion, rust, and other environmental factors.

- Mixed and applied undercoating materials according to manufacturer’s specifications.

- Inspected vehicles for damage or areas requiring additional undercoating.

- Prepared vehicles for undercoating by cleaning and masking off areas not to be coated.

Accomplishments

- Successfully implemented a new undercoating process that reduced material waste by 20%, enhancing efficiency and sustainability.

- Collaborated with research and development to develop an innovative coating solution that improved paint adhesion and extended vehicle lifespan.

- Led a team of Undercoaters to achieve a 15% increase in productivity, optimizing workflow and maximizing resources.

- Developed a customized undercoating solution for specialized vehicles, meeting specific performance requirements in challenging environments.

- Implemented a quality control program that reduced rework by 10%, ensuring consistency and minimizing errors.

Awards

- Recognized by industry peers for excellence in Undercoating techniques, receiving the Golden Brush award.

- Awarded Undercoater of the Year for outstanding performance in applying protective coatings, ensuring optimal vehicle longevity.

- Recognized by management for exceptional attention to detail and highquality undercoating, resulting in increased customer satisfaction.

- Received Safety Champion award for promoting safe work practices and ensuring the wellbeing of the team.

Certificates

- SSPCQP 1

- NACE CIP Level 1

- OSHA 10Hour Safety Training

- CPR and First Aid Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Undercoater

- Highlight your technical skills and experience in undercoating application and material preparation.

- Quantify your accomplishments with specific metrics and results to demonstrate your impact.

- Showcase your problem-solving abilities and experience in troubleshooting and resolving undercoating issues.

- Obtain relevant certifications in undercoating or automotive maintenance to enhance your credibility.

Essential Experience Highlights for a Strong Undercoater Resume

- Apply undercoating materials to vehicle undercarriages according to specifications

- Prepare and mix undercoating materials, ensuring proper consistency and application

- Maintain and calibrate undercoating equipment to ensure optimal performance

- Inspect vehicles before and after undercoating to assess surface condition and ensure quality

- Conduct quality control checks to verify the effectiveness and durability of undercoating

- Troubleshoot and resolve undercoating application issues, ensuring timely completion

- Maintain a clean and organized work area, adhering to health and safety regulations

Frequently Asked Questions (FAQ’s) For Undercoater

What is the primary role of an Undercoater?

An Undercoater is responsible for applying protective coatings to the undercarriage of vehicles to prevent corrosion, improve durability, and enhance the lifespan of the vehicle.

What are the key skills required for an Undercoater?

Essential skills for an Undercoater include coating application techniques, material preparation, equipment maintenance, health and safety compliance, quality control, and inspection procedures.

What are the career prospects for an Undercoater?

Undercoaters with experience and expertise can advance to supervisory or management roles within the automotive industry. They may also specialize in developing and testing new undercoating products and solutions.

What are the educational qualifications required to become an Undercoater?

While formal educational qualifications may vary depending on the employer, a high school diploma or equivalent is generally sufficient. However, some employers may prefer candidates with a degree in chemical engineering or a related field.

What safety precautions should Undercoaters observe?

Undercoaters must adhere to strict safety protocols, including wearing appropriate protective gear, ensuring proper ventilation, and handling chemicals according to MSDS guidelines.

What is the importance of quality control in undercoating?

Quality control is essential in undercoating to ensure the effectiveness and durability of the protective coating. Undercoaters must conduct thorough inspections and tests to verify the proper application, adhesion, and performance of the undercoating.

What are the different types of undercoating materials?

Common undercoating materials include asphalt-based coatings, rubberized coatings, and wax-based coatings. Each type has its unique properties and applications, and the choice of material depends on factors such as the vehicle’s intended use and environmental conditions.