Are you a seasoned Chemical Etch Operator seeking a new career path? Discover our professionally built Chemical Etch Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

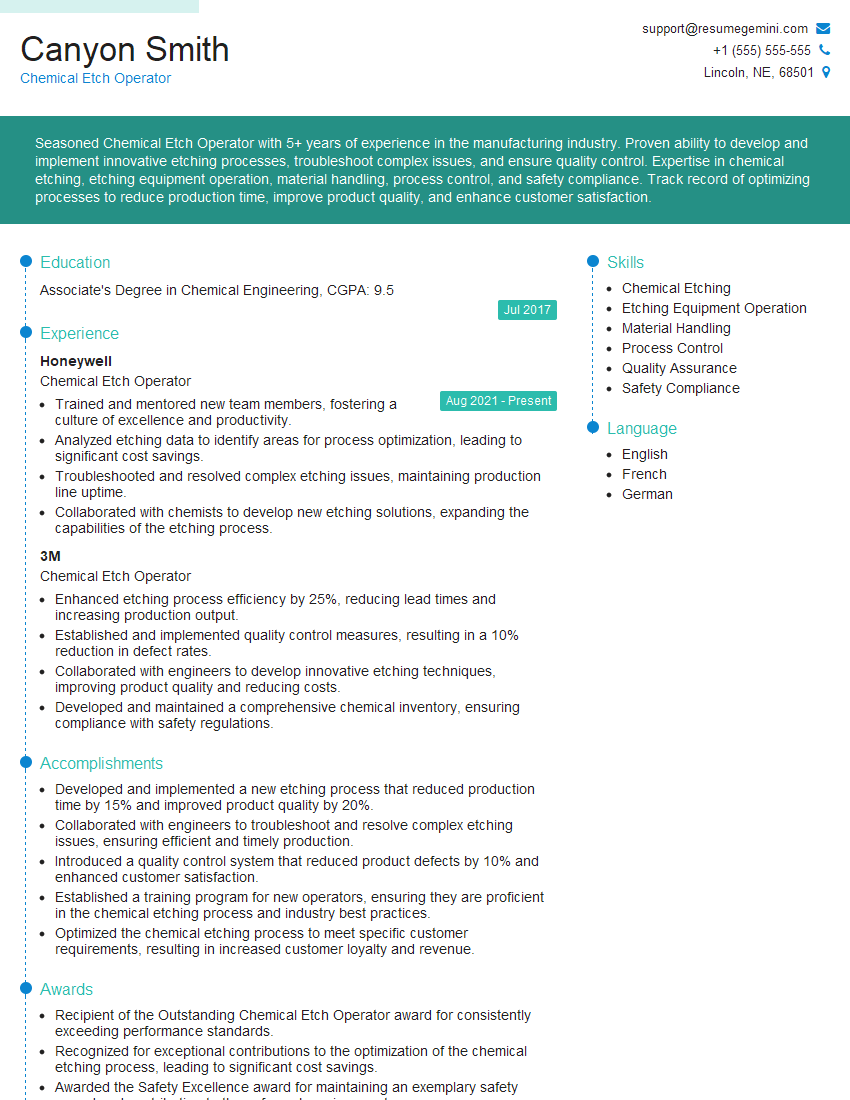

Canyon Smith

Chemical Etch Operator

Summary

Seasoned Chemical Etch Operator with 5+ years of experience in the manufacturing industry. Proven ability to develop and implement innovative etching processes, troubleshoot complex issues, and ensure quality control. Expertise in chemical etching, etching equipment operation, material handling, process control, and safety compliance. Track record of optimizing processes to reduce production time, improve product quality, and enhance customer satisfaction.

Education

Associate’s Degree in Chemical Engineering

July 2017

Skills

- Chemical Etching

- Etching Equipment Operation

- Material Handling

- Process Control

- Quality Assurance

- Safety Compliance

Work Experience

Chemical Etch Operator

- Trained and mentored new team members, fostering a culture of excellence and productivity.

- Analyzed etching data to identify areas for process optimization, leading to significant cost savings.

- Troubleshooted and resolved complex etching issues, maintaining production line uptime.

- Collaborated with chemists to develop new etching solutions, expanding the capabilities of the etching process.

Chemical Etch Operator

- Enhanced etching process efficiency by 25%, reducing lead times and increasing production output.

- Established and implemented quality control measures, resulting in a 10% reduction in defect rates.

- Collaborated with engineers to develop innovative etching techniques, improving product quality and reducing costs.

- Developed and maintained a comprehensive chemical inventory, ensuring compliance with safety regulations.

Accomplishments

- Developed and implemented a new etching process that reduced production time by 15% and improved product quality by 20%.

- Collaborated with engineers to troubleshoot and resolve complex etching issues, ensuring efficient and timely production.

- Introduced a quality control system that reduced product defects by 10% and enhanced customer satisfaction.

- Established a training program for new operators, ensuring they are proficient in the chemical etching process and industry best practices.

- Optimized the chemical etching process to meet specific customer requirements, resulting in increased customer loyalty and revenue.

Awards

- Recipient of the Outstanding Chemical Etch Operator award for consistently exceeding performance standards.

- Recognized for exceptional contributions to the optimization of the chemical etching process, leading to significant cost savings.

- Awarded the Safety Excellence award for maintaining an exemplary safety record and contributing to the safe work environment.

- Received the Innovation Award for developing an innovative etching technique that improved the precision and accuracy of the process.

Certificates

- OSHA 30Hour Hazmat

- National Institute for Certification in Engineering Technologies (NICET)

- American Society for Nondestructive Testing (ASNT)

- Institute of Printed Circuits (IPC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chemical Etch Operator

- Highlight your expertise in chemical etching and etching equipment operation.

- Quantify your accomplishments with specific metrics, such as reduced production time or improved product quality.

- Emphasize your problem-solving abilities and experience in troubleshooting complex etching issues.

- Demonstrate your commitment to safety and quality control by mentioning relevant certifications or training.

- Showcase your ability to work independently and as part of a team to achieve goals.

Essential Experience Highlights for a Strong Chemical Etch Operator Resume

- Develop and optimize chemical etching processes to meet specific product requirements.

- Operate etching equipment and handle materials safely and efficiently.

- Control and monitor process parameters to ensure product quality and consistency.

- Troubleshoot and resolve complex etching issues to minimize downtime and maintain productivity.

- Implement quality control measures to identify and eliminate product defects.

- Train and mentor new operators to ensure proficiency in etching techniques and safety protocols.

- Collaborate with engineers and production team to improve etching processes and enhance overall efficiency.

Frequently Asked Questions (FAQ’s) For Chemical Etch Operator

What is the role of a Chemical Etch Operator?

A Chemical Etch Operator is responsible for operating chemical etching equipment, controlling process parameters, troubleshooting issues, and ensuring product quality in the manufacturing industry.

What skills are required to be a successful Chemical Etch Operator?

Essential skills include proficiency in chemical etching, etching equipment operation, material handling, process control, quality assurance, and safety compliance.

What are the career prospects for Chemical Etch Operators?

With experience and additional training, Chemical Etch Operators can advance to roles such as Process Technician, Quality Control Inspector, or Production Supervisor.

What are the key challenges faced by Chemical Etch Operators?

Common challenges include ensuring product quality and consistency, troubleshooting complex etching issues, and adhering to safety regulations.

What are the safety precautions that Chemical Etch Operators must follow?

Chemical Etch Operators must wear appropriate protective gear, follow safe handling procedures, and be aware of potential hazards associated with chemicals and etching processes.

What industries employ Chemical Etch Operators?

Chemical Etch Operators find employment in various industries, including electronics, automotive, aerospace, and medical device manufacturing.

How can I improve my chances of getting hired as a Chemical Etch Operator?

Obtain relevant certifications or training, gain practical experience through internships or apprenticeships, and highlight your skills and experience in your resume and cover letter.