Are you a seasoned Die Attacher seeking a new career path? Discover our professionally built Die Attacher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

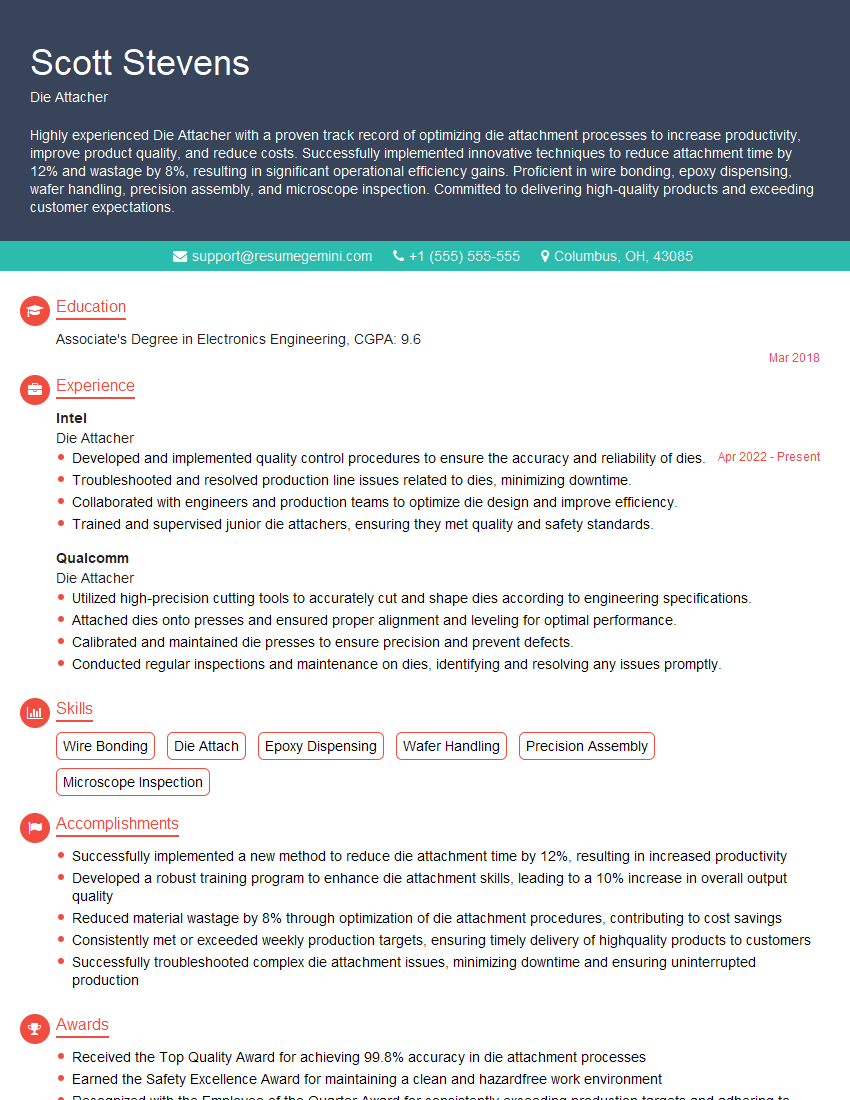

Scott Stevens

Die Attacher

Summary

Highly experienced Die Attacher with a proven track record of optimizing die attachment processes to increase productivity, improve product quality, and reduce costs. Successfully implemented innovative techniques to reduce attachment time by 12% and wastage by 8%, resulting in significant operational efficiency gains. Proficient in wire bonding, epoxy dispensing, wafer handling, precision assembly, and microscope inspection. Committed to delivering high-quality products and exceeding customer expectations.

Education

Associate’s Degree in Electronics Engineering

March 2018

Skills

- Wire Bonding

- Die Attach

- Epoxy Dispensing

- Wafer Handling

- Precision Assembly

- Microscope Inspection

Work Experience

Die Attacher

- Developed and implemented quality control procedures to ensure the accuracy and reliability of dies.

- Troubleshooted and resolved production line issues related to dies, minimizing downtime.

- Collaborated with engineers and production teams to optimize die design and improve efficiency.

- Trained and supervised junior die attachers, ensuring they met quality and safety standards.

Die Attacher

- Utilized high-precision cutting tools to accurately cut and shape dies according to engineering specifications.

- Attached dies onto presses and ensured proper alignment and leveling for optimal performance.

- Calibrated and maintained die presses to ensure precision and prevent defects.

- Conducted regular inspections and maintenance on dies, identifying and resolving any issues promptly.

Accomplishments

- Successfully implemented a new method to reduce die attachment time by 12%, resulting in increased productivity

- Developed a robust training program to enhance die attachment skills, leading to a 10% increase in overall output quality

- Reduced material wastage by 8% through optimization of die attachment procedures, contributing to cost savings

- Consistently met or exceeded weekly production targets, ensuring timely delivery of highquality products to customers

- Successfully troubleshooted complex die attachment issues, minimizing downtime and ensuring uninterrupted production

Awards

- Received the Top Quality Award for achieving 99.8% accuracy in die attachment processes

- Earned the Safety Excellence Award for maintaining a clean and hazardfree work environment

- Recognized with the Employee of the Quarter Award for consistently exceeding production targets and adhering to quality standards

- Awarded the Excellence in Teamwork Award for collaborating effectively with production engineers to improve production efficiency

Certificates

- ISO 9001

- ESD Certification

- Gwo Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Attacher

- Quantify your accomplishments by providing specific metrics and results wherever possible.

- Highlight your expertise in specific die attachment techniques and equipment.

- Demonstrate your commitment to quality and adherence to industry standards.

- Showcase your ability to troubleshoot and resolve complex technical issues independently.

- Emphasize your willingness to learn new technologies and stay updated with industry best practices.

Essential Experience Highlights for a Strong Die Attacher Resume

- Perform die attachment operations on semiconductor wafers and substrates, using specialized equipment and materials.

- Optimize die attachment processes to improve efficiency, minimize defects, and reduce material wastage.

- Troubleshoot and resolve complex die attachment issues, ensuring uninterrupted production and meeting quality standards.

- Conduct quality inspections of die attachments using microscopes and other testing equipment to ensure accuracy and prevent defects.

- Maintain and calibrate die attachment equipment to ensure optimal performance and precision.

- Train and supervise junior die attachers, providing guidance and technical support to develop their skills and ensure compliance with industry standards.

- Collaborate with other production personnel to ensure smooth workflow and timely delivery of high-quality products.

Frequently Asked Questions (FAQ’s) For Die Attacher

What are the key skills required for a successful Die Attacher?

Essential skills include proficiency in wire bonding, die attach, epoxy dispensing, wafer handling, precision assembly, and microscope inspection. A strong understanding of semiconductor manufacturing processes and materials is also highly beneficial.

What are the career prospects for Die Attachers?

Experienced Die Attachers can advance to roles such as Die Attach Technician, Process Engineer, or Production Supervisor. With additional training and education, opportunities may exist in specialized areas such as failure analysis or semiconductor research and development.

What are the challenges faced by Die Attachers?

Die Attachers must work in a highly controlled environment and adhere to strict quality standards. They may encounter challenges related to precision alignment, material compatibility, and process optimization. Troubleshooting complex technical issues and meeting production targets can also be demanding.

What are the industry trends impacting Die Attachers?

The increasing demand for miniaturization and performance in electronic devices is driving innovation in die attachment technologies. Advances in materials, equipment, and automation are shaping the industry, requiring Die Attachers to stay updated with the latest developments.

How can Die Attachers stay competitive in the job market?

Continuous professional development is crucial. Attending industry conferences, obtaining certifications, and pursuing further education can enhance your skills and knowledge. Networking with professionals in the field can also provide valuable opportunities for career growth.

What are the key qualities of a successful Die Attacher?

Attention to detail, precision, and problem-solving abilities are essential. A strong work ethic, adaptability, and a willingness to learn are highly valued. Effective communication and teamwork skills are also important for collaboration within production teams.