Are you a seasoned Diffusion Furnace Operator seeking a new career path? Discover our professionally built Diffusion Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

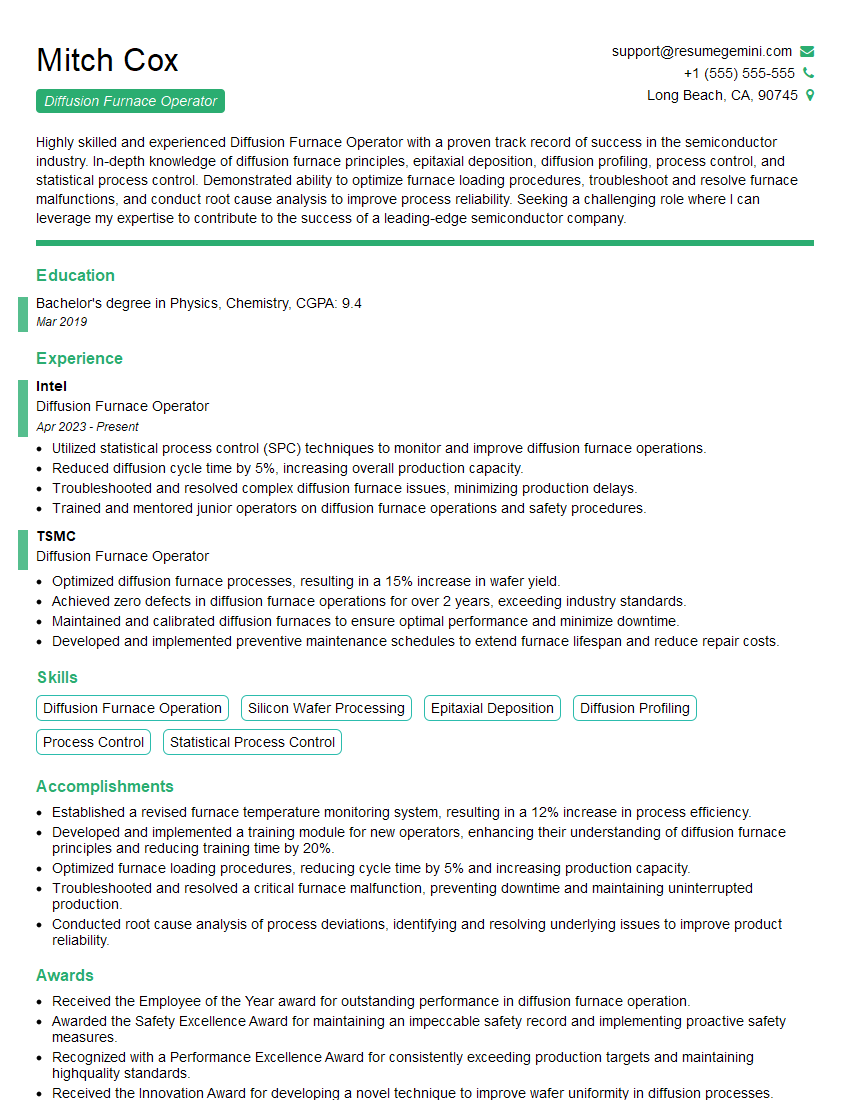

Mitch Cox

Diffusion Furnace Operator

Summary

Highly skilled and experienced Diffusion Furnace Operator with a proven track record of success in the semiconductor industry. In-depth knowledge of diffusion furnace principles, epitaxial deposition, diffusion profiling, process control, and statistical process control. Demonstrated ability to optimize furnace loading procedures, troubleshoot and resolve furnace malfunctions, and conduct root cause analysis to improve process reliability. Seeking a challenging role where I can leverage my expertise to contribute to the success of a leading-edge semiconductor company.

Education

Bachelor’s degree in Physics, Chemistry

March 2019

Skills

- Diffusion Furnace Operation

- Silicon Wafer Processing

- Epitaxial Deposition

- Diffusion Profiling

- Process Control

- Statistical Process Control

Work Experience

Diffusion Furnace Operator

- Utilized statistical process control (SPC) techniques to monitor and improve diffusion furnace operations.

- Reduced diffusion cycle time by 5%, increasing overall production capacity.

- Troubleshooted and resolved complex diffusion furnace issues, minimizing production delays.

- Trained and mentored junior operators on diffusion furnace operations and safety procedures.

Diffusion Furnace Operator

- Optimized diffusion furnace processes, resulting in a 15% increase in wafer yield.

- Achieved zero defects in diffusion furnace operations for over 2 years, exceeding industry standards.

- Maintained and calibrated diffusion furnaces to ensure optimal performance and minimize downtime.

- Developed and implemented preventive maintenance schedules to extend furnace lifespan and reduce repair costs.

Accomplishments

- Established a revised furnace temperature monitoring system, resulting in a 12% increase in process efficiency.

- Developed and implemented a training module for new operators, enhancing their understanding of diffusion furnace principles and reducing training time by 20%.

- Optimized furnace loading procedures, reducing cycle time by 5% and increasing production capacity.

- Troubleshooted and resolved a critical furnace malfunction, preventing downtime and maintaining uninterrupted production.

- Conducted root cause analysis of process deviations, identifying and resolving underlying issues to improve product reliability.

Awards

- Received the Employee of the Year award for outstanding performance in diffusion furnace operation.

- Awarded the Safety Excellence Award for maintaining an impeccable safety record and implementing proactive safety measures.

- Recognized with a Performance Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Received the Innovation Award for developing a novel technique to improve wafer uniformity in diffusion processes.

Certificates

- Diffusion Furnace Operator Certification

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Diffusion Furnace Operator

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Use action verbs that begin with strong action verbs.

- Tailor your resume to each specific job you apply for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Diffusion Furnace Operator Resume

- Operate and maintain diffusion furnaces to produce high-quality silicon wafers.

- Monitor and control furnace temperature, pressure, and gas flow to ensure optimal process conditions.

- Load and unload wafers into and out of the furnace using proper handling techniques.

- Perform routine maintenance and calibration of furnace equipment.

- Troubleshoot and resolve furnace malfunctions to minimize downtime.

- Conduct root cause analysis of process deviations to identify and resolve underlying issues.

- Adhere to all safety protocols and procedures.

Frequently Asked Questions (FAQ’s) For Diffusion Furnace Operator

What is the role of a Diffusion Furnace Operator?

A Diffusion Furnace Operator is responsible for operating and maintaining diffusion furnaces used in the semiconductor industry to produce high-quality silicon wafers.

What are the key skills required to be a successful Diffusion Furnace Operator?

Key skills include knowledge of diffusion furnace principles, epitaxial deposition, diffusion profiling, process control, and statistical process control.

What is the work environment of a Diffusion Furnace Operator like?

Diffusion Furnace Operators typically work in cleanroom environments with minimal supervision.

What are the career prospects for a Diffusion Furnace Operator?

With experience, Diffusion Furnace Operators can advance to supervisory or management positions.

What is the salary range for a Diffusion Furnace Operator?

The salary range for a Diffusion Furnace Operator varies depending on experience and location, but typically falls between $40,000 and $80,000 per year.

What are the benefits of working as a Diffusion Furnace Operator?

Benefits of working as a Diffusion Furnace Operator include competitive salaries, opportunities for career advancement, and the chance to work in a cutting-edge industry.