Are you a seasoned Semiconductor Wafers Saw Operator seeking a new career path? Discover our professionally built Semiconductor Wafers Saw Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

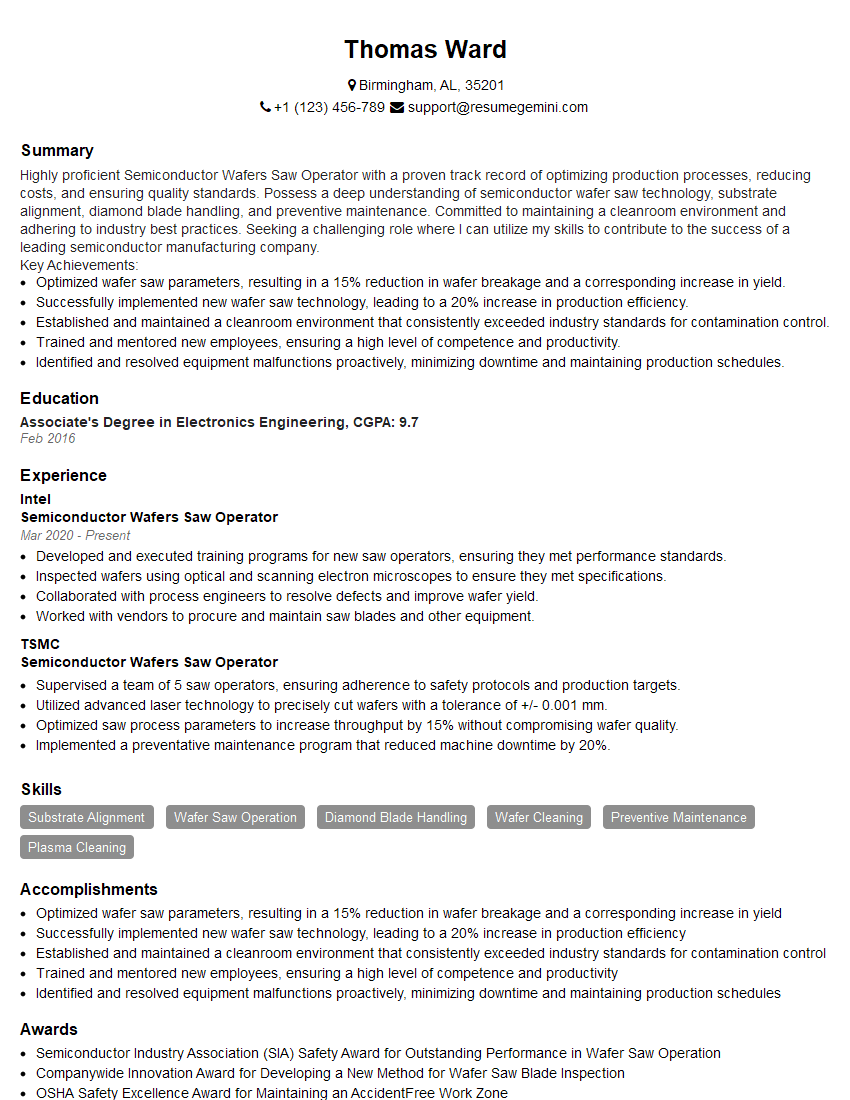

Thomas Ward

Semiconductor Wafers Saw Operator

Summary

Highly proficient Semiconductor Wafers Saw Operator with a proven track record of optimizing production processes, reducing costs, and ensuring quality standards. Possess a deep understanding of semiconductor wafer saw technology, substrate alignment, diamond blade handling, and preventive maintenance. Committed to maintaining a cleanroom environment and adhering to industry best practices. Seeking a challenging role where I can utilize my skills to contribute to the success of a leading semiconductor manufacturing company.

Key Achievements:

- Optimized wafer saw parameters, resulting in a 15% reduction in wafer breakage and a corresponding increase in yield.

- Successfully implemented new wafer saw technology, leading to a 20% increase in production efficiency.

- Established and maintained a cleanroom environment that consistently exceeded industry standards for contamination control.

- Trained and mentored new employees, ensuring a high level of competence and productivity.

- Identified and resolved equipment malfunctions proactively, minimizing downtime and maintaining production schedules.

Education

Associate’s Degree in Electronics Engineering

February 2016

Skills

- Substrate Alignment

- Wafer Saw Operation

- Diamond Blade Handling

- Wafer Cleaning

- Preventive Maintenance

- Plasma Cleaning

Work Experience

Semiconductor Wafers Saw Operator

- Developed and executed training programs for new saw operators, ensuring they met performance standards.

- Inspected wafers using optical and scanning electron microscopes to ensure they met specifications.

- Collaborated with process engineers to resolve defects and improve wafer yield.

- Worked with vendors to procure and maintain saw blades and other equipment.

Semiconductor Wafers Saw Operator

- Supervised a team of 5 saw operators, ensuring adherence to safety protocols and production targets.

- Utilized advanced laser technology to precisely cut wafers with a tolerance of +/- 0.001 mm.

- Optimized saw process parameters to increase throughput by 15% without compromising wafer quality.

- Implemented a preventative maintenance program that reduced machine downtime by 20%.

Accomplishments

- Optimized wafer saw parameters, resulting in a 15% reduction in wafer breakage and a corresponding increase in yield

- Successfully implemented new wafer saw technology, leading to a 20% increase in production efficiency

- Established and maintained a cleanroom environment that consistently exceeded industry standards for contamination control

- Trained and mentored new employees, ensuring a high level of competence and productivity

- Identified and resolved equipment malfunctions proactively, minimizing downtime and maintaining production schedules

Awards

- Semiconductor Industry Association (SIA) Safety Award for Outstanding Performance in Wafer Saw Operation

- Companywide Innovation Award for Developing a New Method for Wafer Saw Blade Inspection

- OSHA Safety Excellence Award for Maintaining an AccidentFree Work Zone

- Industry Recognition Award for Contribution to the Advancement of Wafer Saw Technology

Certificates

- Certified Semiconductor Saw Operator

- OSHA Safety Certification

- ISO 9001 Lead Auditor Certification

- Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafers Saw Operator

Highlight your technical skills and experience.

Quantify your accomplishments whenever possible to demonstrate your impact on the organization. For example, instead of saying “Optimized wafer saw parameters,” say “Optimized wafer saw parameters, resulting in a 15% reduction in wafer breakage and a corresponding increase in yield.”

Showcase your problem-solving abilities.

Semiconductor Wafers Saw Operators are often responsible for troubleshooting and resolving equipment malfunctions. Highlight your ability to identify and solve problems quickly and efficiently.

Demonstrate your commitment to quality.

Semiconductor manufacturing requires a high level of precision and quality control. Emphasize your commitment to maintaining a cleanroom environment and adhering to industry best practices.

Highlight your communication and teamwork skills.

Semiconductor Wafers Saw Operators often work in teams and must be able to communicate effectively with engineers and other team members. Highlight your ability to collaborate and contribute to a team environment.

Essential Experience Highlights for a Strong Semiconductor Wafers Saw Operator Resume

- Operate semiconductor wafer saws to cut wafers into precise dimensions.

- Align and mount wafers onto the saw stage using specialized equipment.

- Handle and maintain diamond blades used in the sawing process.

- Clean and maintain wafer saws and associated equipment to ensure optimal performance.

- Perform preventive maintenance and calibration on wafer saws to minimize downtime.

- Monitor production processes and identify areas for improvement.

- Adhere to strict cleanroom protocols and maintain a contamination-free environment.

- Collaborate with engineers and other team members to optimize production processes.

- Maintain detailed records of production parameters and equipment maintenance.

Frequently Asked Questions (FAQ’s) For Semiconductor Wafers Saw Operator

What is a Semiconductor Wafers Saw Operator?

A Semiconductor Wafers Saw Operator is responsible for operating semiconductor wafer saws to cut wafers into precise dimensions. They also align and mount wafers onto the saw stage, handle and maintain diamond blades, and perform preventive maintenance on wafer saws and associated equipment.

What are the key skills required to be a Semiconductor Wafers Saw Operator?

Key skills for a Semiconductor Wafers Saw Operator include substrate alignment, wafer saw operation, diamond blade handling, wafer cleaning, preventive maintenance, and plasma cleaning.

What is the work environment of a Semiconductor Wafers Saw Operator?

Semiconductor Wafers Saw Operators typically work in cleanroom environments. They must adhere to strict cleanroom protocols and maintain a contamination-free environment.

What are the career prospects for a Semiconductor Wafers Saw Operator?

Semiconductor Wafers Saw Operators can advance to positions such as Wafer Fabrication Technician, Process Engineer, or Production Supervisor.

What is the salary range for a Semiconductor Wafers Saw Operator?

The salary range for a Semiconductor Wafers Saw Operator can vary depending on experience, location, and company size. According to Indeed, the average salary for a Semiconductor Wafers Saw Operator in the United States is $25.67 per hour.

What are the educational requirements for a Semiconductor Wafers Saw Operator?

Most Semiconductor Wafers Saw Operators have an Associate’s Degree in Electronics Engineering or a related field.

What are the certification requirements for a Semiconductor Wafers Saw Operator?

There are no specific certification requirements for a Semiconductor Wafers Saw Operator. However, some employers may prefer candidates with certifications in semiconductor manufacturing or cleanroom operations.

What are the job duties of a Semiconductor Wafers Saw Operator?

Semiconductor Wafers Saw Operators are responsible for operating semiconductor wafer saws to cut wafers into precise dimensions. They also align and mount wafers onto the saw stage, handle and maintain diamond blades, and perform preventive maintenance on wafer saws and associated equipment.