Are you a seasoned Wafer Polishing Worker seeking a new career path? Discover our professionally built Wafer Polishing Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

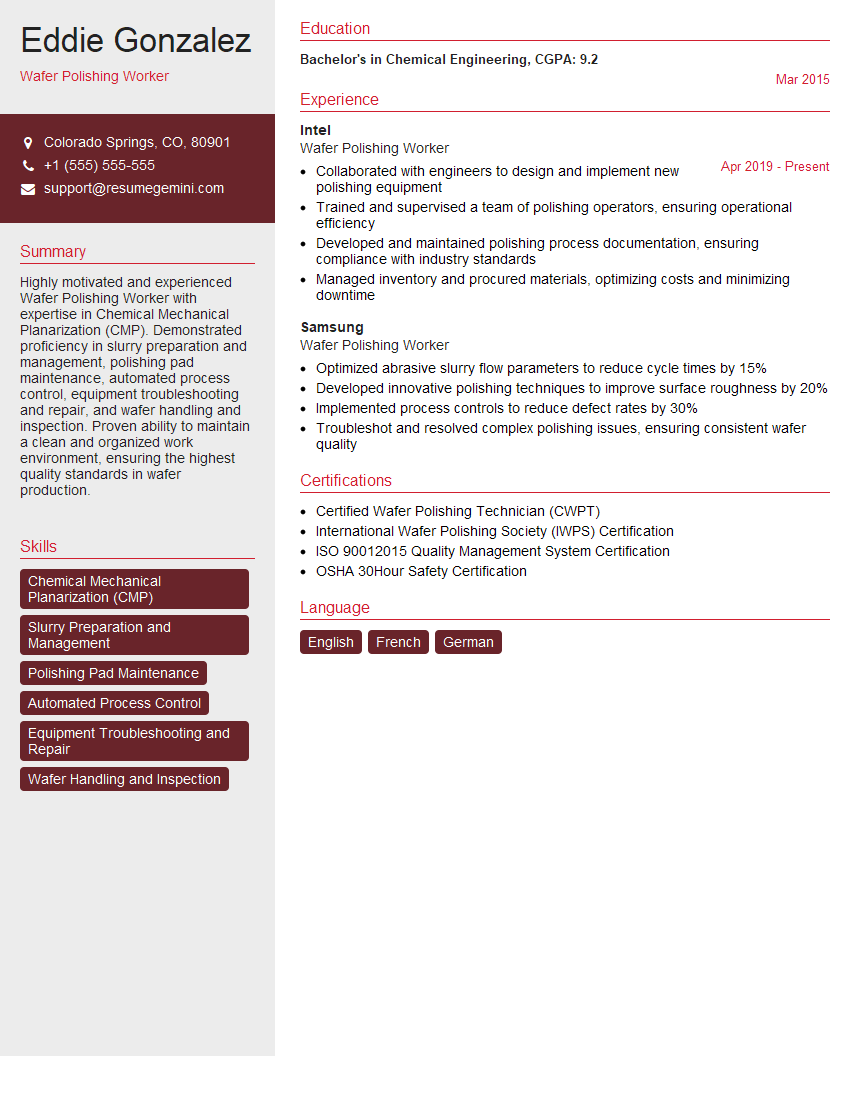

Eddie Gonzalez

Wafer Polishing Worker

Summary

Highly motivated and experienced Wafer Polishing Worker with expertise in Chemical Mechanical Planarization (CMP). Demonstrated proficiency in slurry preparation and management, polishing pad maintenance, automated process control, equipment troubleshooting and repair, and wafer handling and inspection. Proven ability to maintain a clean and organized work environment, ensuring the highest quality standards in wafer production.

Education

Bachelor’s in Chemical Engineering

March 2015

Skills

- Chemical Mechanical Planarization (CMP)

- Slurry Preparation and Management

- Polishing Pad Maintenance

- Automated Process Control

- Equipment Troubleshooting and Repair

- Wafer Handling and Inspection

Work Experience

Wafer Polishing Worker

- Collaborated with engineers to design and implement new polishing equipment

- Trained and supervised a team of polishing operators, ensuring operational efficiency

- Developed and maintained polishing process documentation, ensuring compliance with industry standards

- Managed inventory and procured materials, optimizing costs and minimizing downtime

Wafer Polishing Worker

- Optimized abrasive slurry flow parameters to reduce cycle times by 15%

- Developed innovative polishing techniques to improve surface roughness by 20%

- Implemented process controls to reduce defect rates by 30%

- Troubleshot and resolved complex polishing issues, ensuring consistent wafer quality

Certificates

- Certified Wafer Polishing Technician (CWPT)

- International Wafer Polishing Society (IWPS) Certification

- ISO 90012015 Quality Management System Certification

- OSHA 30Hour Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wafer Polishing Worker

- Highlight your technical skills in CMP, including slurry preparation, pad maintenance, and equipment operation.

- Showcase your experience in automated process control and troubleshooting, emphasizing your ability to maintain productivity.

- Quantify your accomplishments with specific metrics, such as improved surface quality or reduced downtime.

- Obtain industry certifications or training programs to demonstrate your commitment to professional development.

Essential Experience Highlights for a Strong Wafer Polishing Worker Resume

- Prepare and manage slurry solutions used in the CMP process

- Maintain polishing pads to ensure optimal performance and surface quality

- Operate and monitor automated CMP equipment, including polishers and scrubbers

- Troubleshoot and repair equipment malfunctions to minimize downtime and maintain productivity

- Handle and inspect wafers throughout the CMP process, ensuring proper handling and surface quality

- Adhere to safety protocols and maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Wafer Polishing Worker

What is the primary role of a Wafer Polishing Worker?

The primary role of a Wafer Polishing Worker is to prepare, maintain, and operate equipment used in the Chemical Mechanical Planarization (CMP) process, ensuring the production of high-quality wafers for semiconductor manufacturing.

What are the key skills required for a successful Wafer Polishing Worker?

Key skills for a successful Wafer Polishing Worker include expertise in CMP, slurry preparation and management, polishing pad maintenance, automated process control, equipment troubleshooting and repair, and wafer handling and inspection.

What is the typical work environment for a Wafer Polishing Worker?

Wafer Polishing Workers typically work in cleanrooms or other controlled environments, ensuring a clean and dust-free workspace for wafer processing.

What are the career advancement opportunities for a Wafer Polishing Worker?

With experience and additional training, Wafer Polishing Workers can advance to roles such as CMP Process Engineer, Quality Control Inspector, or Production Supervisor.

What are the safety precautions that a Wafer Polishing Worker must observe?

Wafer Polishing Workers must adhere to strict safety protocols, including wearing protective gear, handling chemicals with care, and following proper equipment operation procedures.

How can I prepare for a career as a Wafer Polishing Worker?

To prepare for a career as a Wafer Polishing Worker, consider pursuing a degree in Chemical Engineering or a related field, gaining experience in a cleanroom environment, and obtaining industry certifications or training programs.

What are the salary expectations for a Wafer Polishing Worker?

Salary expectations for a Wafer Polishing Worker can vary based on experience, location, and company size. According to Glassdoor, the average salary for a Wafer Polishing Worker in the United States is around $25,000 per year.