Are you a seasoned Wafer Production Worker seeking a new career path? Discover our professionally built Wafer Production Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

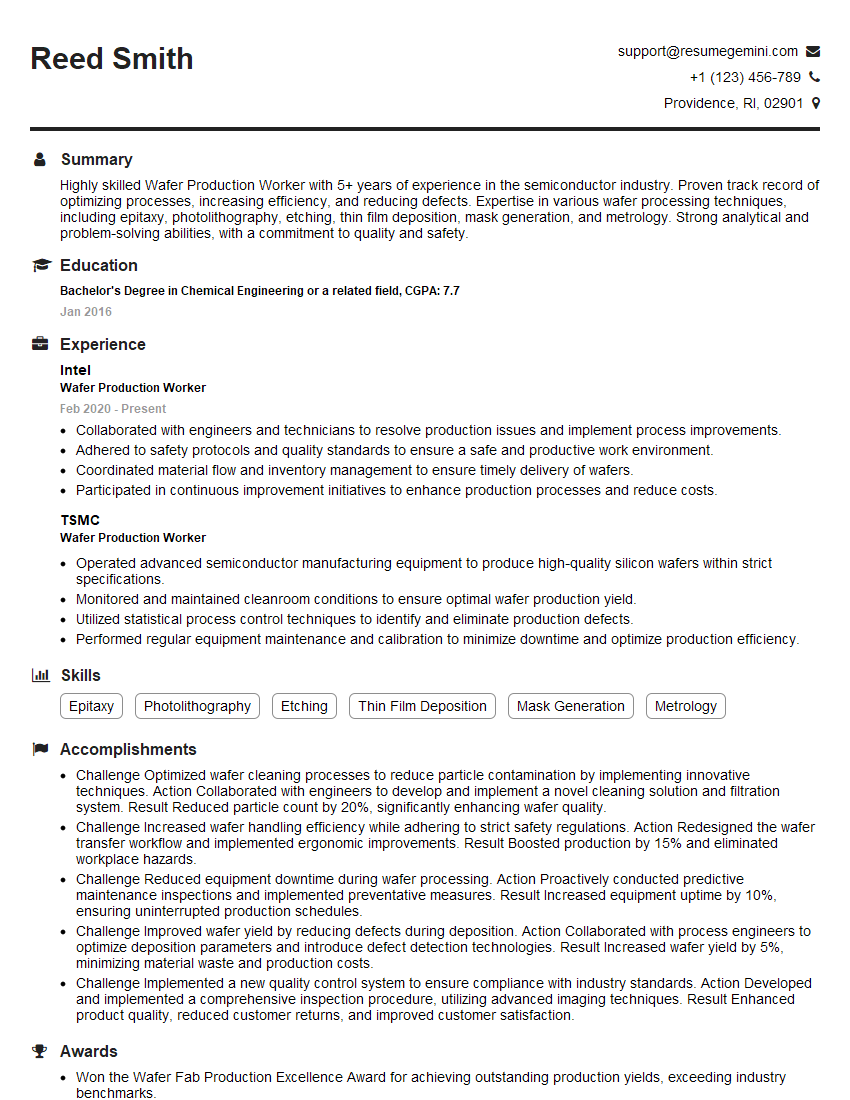

Reed Smith

Wafer Production Worker

Summary

Highly skilled Wafer Production Worker with 5+ years of experience in the semiconductor industry. Proven track record of optimizing processes, increasing efficiency, and reducing defects. Expertise in various wafer processing techniques, including epitaxy, photolithography, etching, thin film deposition, mask generation, and metrology. Strong analytical and problem-solving abilities, with a commitment to quality and safety.

Education

Bachelor’s Degree in Chemical Engineering or a related field

January 2016

Skills

- Epitaxy

- Photolithography

- Etching

- Thin Film Deposition

- Mask Generation

- Metrology

Work Experience

Wafer Production Worker

- Collaborated with engineers and technicians to resolve production issues and implement process improvements.

- Adhered to safety protocols and quality standards to ensure a safe and productive work environment.

- Coordinated material flow and inventory management to ensure timely delivery of wafers.

- Participated in continuous improvement initiatives to enhance production processes and reduce costs.

Wafer Production Worker

- Operated advanced semiconductor manufacturing equipment to produce high-quality silicon wafers within strict specifications.

- Monitored and maintained cleanroom conditions to ensure optimal wafer production yield.

- Utilized statistical process control techniques to identify and eliminate production defects.

- Performed regular equipment maintenance and calibration to minimize downtime and optimize production efficiency.

Accomplishments

- Challenge Optimized wafer cleaning processes to reduce particle contamination by implementing innovative techniques. Action Collaborated with engineers to develop and implement a novel cleaning solution and filtration system. Result Reduced particle count by 20%, significantly enhancing wafer quality.

- Challenge Increased wafer handling efficiency while adhering to strict safety regulations. Action Redesigned the wafer transfer workflow and implemented ergonomic improvements. Result Boosted production by 15% and eliminated workplace hazards.

- Challenge Reduced equipment downtime during wafer processing. Action Proactively conducted predictive maintenance inspections and implemented preventative measures. Result Increased equipment uptime by 10%, ensuring uninterrupted production schedules.

- Challenge Improved wafer yield by reducing defects during deposition. Action Collaborated with process engineers to optimize deposition parameters and introduce defect detection technologies. Result Increased wafer yield by 5%, minimizing material waste and production costs.

- Challenge Implemented a new quality control system to ensure compliance with industry standards. Action Developed and implemented a comprehensive inspection procedure, utilizing advanced imaging techniques. Result Enhanced product quality, reduced customer returns, and improved customer satisfaction.

Awards

- Won the Wafer Fab Production Excellence Award for achieving outstanding production yields, exceeding industry benchmarks.

- Recognized with the Excellence in Process Control award for consistently maintaining rigorous process parameters, minimizing defects.

- Received the Employee of the Quarter award for exceptional contributions towards wafer cleaning and preparation, ensuring highquality silicon substrates.

Certificates

- Certified Wafer Process Technician (CWPT)

- Certified Semiconductor Professional (CSP)

- ISO 90012015

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wafer Production Worker

- Highlight your technical skills and experience in wafer processing techniques.

- Quantify your accomplishments with specific metrics, such as percentage improvements in yield or reductions in defects.

- Demonstrate your problem-solving abilities by describing how you have overcome challenges and implemented solutions.

- Showcase your commitment to quality and safety by emphasizing your adherence to industry standards and safety protocols.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Wafer Production Worker Resume

- Operate and maintain wafer processing equipment, including epitaxy reactors, photolithography systems, etchers, and thin film deposition tools

- Perform wafer cleaning, inspection, and defect detection to ensure product quality

- Monitor process parameters and make adjustments to optimize yield and reduce defects

- Troubleshoot and resolve equipment issues to minimize downtime and maintain production schedules

- Implement process improvements and quality control measures to enhance efficiency and product quality

- Maintain a clean and safe work environment, adhering to all safety protocols

Frequently Asked Questions (FAQ’s) For Wafer Production Worker

What is the role of a Wafer Production Worker?

A Wafer Production Worker is responsible for operating and maintaining wafer processing equipment, performing wafer cleaning, inspection, and defect detection, monitoring process parameters, and implementing process improvements to enhance efficiency and product quality.

What are the key skills required for a Wafer Production Worker?

Key skills include expertise in wafer processing techniques such as epitaxy, photolithography, etching, thin film deposition, mask generation, and metrology; strong analytical and problem-solving abilities; and a commitment to quality and safety.

What are the career prospects for a Wafer Production Worker?

Wafer Production Workers can advance to roles such as Process Engineer, Production Supervisor, or Quality Control Manager with experience and additional training.

What is the average salary for a Wafer Production Worker?

The average salary for a Wafer Production Worker varies depending on experience, location, and company, but typically ranges from \$40,000 to \$60,000 per year.

What are the working conditions for a Wafer Production Worker?

Wafer Production Workers typically work in cleanroom environments and may be exposed to hazardous chemicals. They may also work shifts, including nights and weekends.

What is the job outlook for a Wafer Production Worker?

The job outlook for Wafer Production Workers is expected to be good due to the increasing demand for semiconductors in various industries.

What are the educational requirements for a Wafer Production Worker?

Most Wafer Production Workers have a high school diploma or equivalent, but some employers may prefer candidates with a bachelor’s degree in chemical engineering or a related field.

What are the certification requirements for a Wafer Production Worker?

Some employers may require Wafer Production Workers to obtain specific certifications, such as the Semiconductor Manufacturing Technology Certification (SMTC) from the Semiconductor Equipment and Materials International (SEMI).