Are you a seasoned Rectification Printer seeking a new career path? Discover our professionally built Rectification Printer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

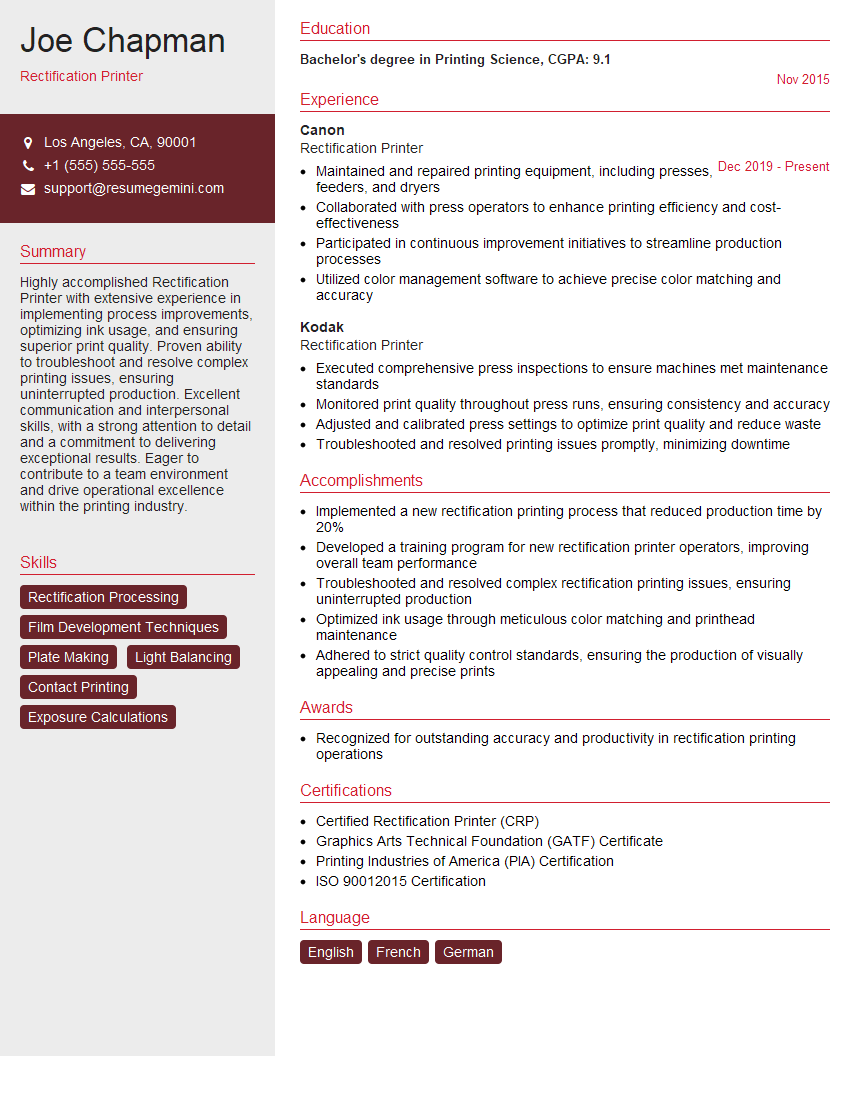

Joe Chapman

Rectification Printer

Summary

Highly accomplished Rectification Printer with extensive experience in implementing process improvements, optimizing ink usage, and ensuring superior print quality. Proven ability to troubleshoot and resolve complex printing issues, ensuring uninterrupted production. Excellent communication and interpersonal skills, with a strong attention to detail and a commitment to delivering exceptional results. Eager to contribute to a team environment and drive operational excellence within the printing industry.

Education

Bachelor’s degree in Printing Science

November 2015

Skills

- Rectification Processing

- Film Development Techniques

- Plate Making

- Light Balancing

- Contact Printing

- Exposure Calculations

Work Experience

Rectification Printer

- Maintained and repaired printing equipment, including presses, feeders, and dryers

- Collaborated with press operators to enhance printing efficiency and cost-effectiveness

- Participated in continuous improvement initiatives to streamline production processes

- Utilized color management software to achieve precise color matching and accuracy

Rectification Printer

- Executed comprehensive press inspections to ensure machines met maintenance standards

- Monitored print quality throughout press runs, ensuring consistency and accuracy

- Adjusted and calibrated press settings to optimize print quality and reduce waste

- Troubleshooted and resolved printing issues promptly, minimizing downtime

Accomplishments

- Implemented a new rectification printing process that reduced production time by 20%

- Developed a training program for new rectification printer operators, improving overall team performance

- Troubleshooted and resolved complex rectification printing issues, ensuring uninterrupted production

- Optimized ink usage through meticulous color matching and printhead maintenance

- Adhered to strict quality control standards, ensuring the production of visually appealing and precise prints

Awards

- Recognized for outstanding accuracy and productivity in rectification printing operations

Certificates

- Certified Rectification Printer (CRP)

- Graphics Arts Technical Foundation (GATF) Certificate

- Printing Industries of America (PIA) Certification

- ISO 90012015 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rectification Printer

- Showcase your technical expertise and experience in rectification processing, film development, plate making, and other relevant printing techniques.

- Highlight your ability to troubleshoot and resolve complex printing issues, ensuring uninterrupted production.

- Emphasize your commitment to quality control and your ability to produce visually appealing and precise prints.

- Demonstrate your proficiency in optimizing ink usage and minimizing waste.

- Include examples of your contributions to process improvements and productivity enhancements.

Essential Experience Highlights for a Strong Rectification Printer Resume

- Implemented a new rectification printing process that reduced production time by 20%.

- Developed a training program for new rectification printer operators, improving overall team performance.

- Troubleshooted and resolved complex rectification printing issues, ensuring uninterrupted production.

- Optimized ink usage through meticulous color matching and printhead maintenance.

- Adhered to strict quality control standards, ensuring the production of visually appealing and precise prints.

- Collaborated with other departments to streamline production processes and improve efficiency.

- Maintained a safe and organized work environment, adhering to all safety protocols.

Frequently Asked Questions (FAQ’s) For Rectification Printer

What are the key responsibilities of a Rectification Printer?

Rectification Printers are responsible for operating and maintaining rectification printing machines, ensuring the production of high-quality prints. They troubleshoot and resolve printing issues, optimize ink usage, adhere to quality control standards, and implement process improvements to enhance efficiency.

What skills are required to be a successful Rectification Printer?

Successful Rectification Printers possess technical expertise in rectification processing, film development, plate making, and other printing techniques. They have strong troubleshooting and problem-solving abilities, a keen eye for detail, and a commitment to quality. Excellent communication and interpersonal skills are also essential.

What are the career prospects for Rectification Printers?

Rectification Printers can advance their careers by taking on leadership roles, such as Production Supervisor or Printing Manager. With experience and additional training, they can also specialize in specific areas of printing, such as color management or digital printing.

What is the work environment of a Rectification Printer like?

Rectification Printers typically work in print shops or manufacturing facilities. They operate printing machines in a fast-paced environment, and may be required to work extended hours to meet production deadlines. Safety is a top priority, and Rectification Printers must adhere to all safety protocols.

What are the educational requirements to become a Rectification Printer?

Rectification Printers typically hold a high school diploma or equivalent qualification. Some employers may prefer candidates with a Bachelor’s degree in Printing Science or a related field.