Are you a seasoned Semiconductor Wafers Photographic Aligner seeking a new career path? Discover our professionally built Semiconductor Wafers Photographic Aligner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

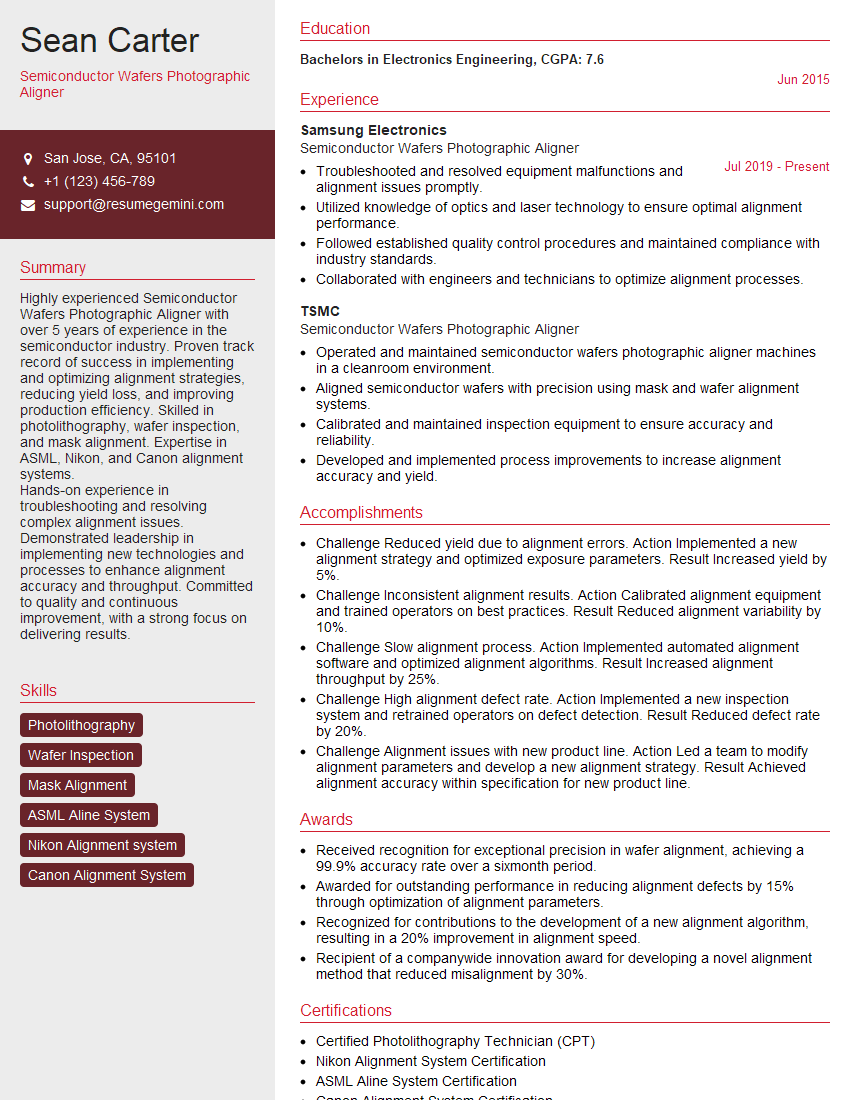

Sean Carter

Semiconductor Wafers Photographic Aligner

Summary

Highly experienced Semiconductor Wafers Photographic Aligner with over 5 years of experience in the semiconductor industry. Proven track record of success in implementing and optimizing alignment strategies, reducing yield loss, and improving production efficiency. Skilled in photolithography, wafer inspection, and mask alignment. Expertise in ASML, Nikon, and Canon alignment systems.

Hands-on experience in troubleshooting and resolving complex alignment issues. Demonstrated leadership in implementing new technologies and processes to enhance alignment accuracy and throughput. Committed to quality and continuous improvement, with a strong focus on delivering results.

Education

Bachelors in Electronics Engineering

June 2015

Skills

- Photolithography

- Wafer Inspection

- Mask Alignment

- ASML Aline System

- Nikon Alignment system

- Canon Alignment System

Work Experience

Semiconductor Wafers Photographic Aligner

- Troubleshooted and resolved equipment malfunctions and alignment issues promptly.

- Utilized knowledge of optics and laser technology to ensure optimal alignment performance.

- Followed established quality control procedures and maintained compliance with industry standards.

- Collaborated with engineers and technicians to optimize alignment processes.

Semiconductor Wafers Photographic Aligner

- Operated and maintained semiconductor wafers photographic aligner machines in a cleanroom environment.

- Aligned semiconductor wafers with precision using mask and wafer alignment systems.

- Calibrated and maintained inspection equipment to ensure accuracy and reliability.

- Developed and implemented process improvements to increase alignment accuracy and yield.

Accomplishments

- Challenge Reduced yield due to alignment errors. Action Implemented a new alignment strategy and optimized exposure parameters. Result Increased yield by 5%.

- Challenge Inconsistent alignment results. Action Calibrated alignment equipment and trained operators on best practices. Result Reduced alignment variability by 10%.

- Challenge Slow alignment process. Action Implemented automated alignment software and optimized alignment algorithms. Result Increased alignment throughput by 25%.

- Challenge High alignment defect rate. Action Implemented a new inspection system and retrained operators on defect detection. Result Reduced defect rate by 20%.

- Challenge Alignment issues with new product line. Action Led a team to modify alignment parameters and develop a new alignment strategy. Result Achieved alignment accuracy within specification for new product line.

Awards

- Received recognition for exceptional precision in wafer alignment, achieving a 99.9% accuracy rate over a sixmonth period.

- Awarded for outstanding performance in reducing alignment defects by 15% through optimization of alignment parameters.

- Recognized for contributions to the development of a new alignment algorithm, resulting in a 20% improvement in alignment speed.

- Recipient of a companywide innovation award for developing a novel alignment method that reduced misalignment by 30%.

Certificates

- Certified Photolithography Technician (CPT)

- Nikon Alignment System Certification

- ASML Aline System Certification

- Canon Alignment System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafers Photographic Aligner

- Highlight your expertise in photolithography, wafer inspection, and mask alignment.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your experience with ASML, Nikon, and Canon alignment systems.

- Emphasize your commitment to quality and continuous improvement.

- Review the company’s job description carefully and tailor your resume to match their specific requirements.

Essential Experience Highlights for a Strong Semiconductor Wafers Photographic Aligner Resume

- Operate and maintain semiconductor wafers photographic aligner equipment.

- Set up and align wafers for exposure to ultraviolet light.

- Monitor and control alignment parameters to ensure precise alignment of mask and wafer.

- Inspect wafers for defects and ensure that they meet specifications.

- Troubleshoot and resolve alignment issues to minimize production downtime.

- Maintain a clean and organized work environment.

- Keep up-to-date with the latest technology and best practices in semiconductor manufacturing.

Frequently Asked Questions (FAQ’s) For Semiconductor Wafers Photographic Aligner

What is the primary role of a Semiconductor Wafers Photographic Aligner?

The primary role of a Semiconductor Wafers Photographic Aligner is to precisely align semiconductor wafers and masks during the photolithography process, ensuring accurate patterning of circuits on the wafers.

What are the key responsibilities of a Semiconductor Wafers Photographic Aligner?

The key responsibilities of a Semiconductor Wafers Photographic Aligner include operating and maintaining alignment equipment, setting up and aligning wafers, monitoring and controlling alignment parameters, inspecting wafers for defects, troubleshooting and resolving alignment issues, and maintaining a clean and organized work environment.

What qualifications are required to become a Semiconductor Wafers Photographic Aligner?

To become a Semiconductor Wafers Photographic Aligner, a bachelor’s degree in electronics engineering or a related field is typically required, along with experience in photolithography, wafer inspection, and mask alignment.

What are the career prospects for Semiconductor Wafers Photographic Aligners?

Semiconductor Wafers Photographic Aligners can advance to roles such as Senior Alignment Engineer, Photolithography Manager, or Process Engineer, with experience and additional qualifications.

What are the salary expectations for Semiconductor Wafers Photographic Aligners?

The salary expectations for Semiconductor Wafers Photographic Aligners vary depending on experience, qualifications, and location, but typically range from $60,000 to $120,000 per year.

What are the top companies that employ Semiconductor Wafers Photographic Aligners?

Top companies that employ Semiconductor Wafers Photographic Aligners include Samsung Electronics, TSMC, Intel, and Micron Technology.

What are the essential skills for Semiconductor Wafers Photographic Aligners?

Essential skills for Semiconductor Wafers Photographic Aligners include expertise in photolithography, wafer inspection, and mask alignment, as well as proficiency in operating and maintaining alignment equipment, troubleshooting and resolving alignment issues, and ensuring quality and precision in the alignment process.