Are you a seasoned Bonding Molder seeking a new career path? Discover our professionally built Bonding Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

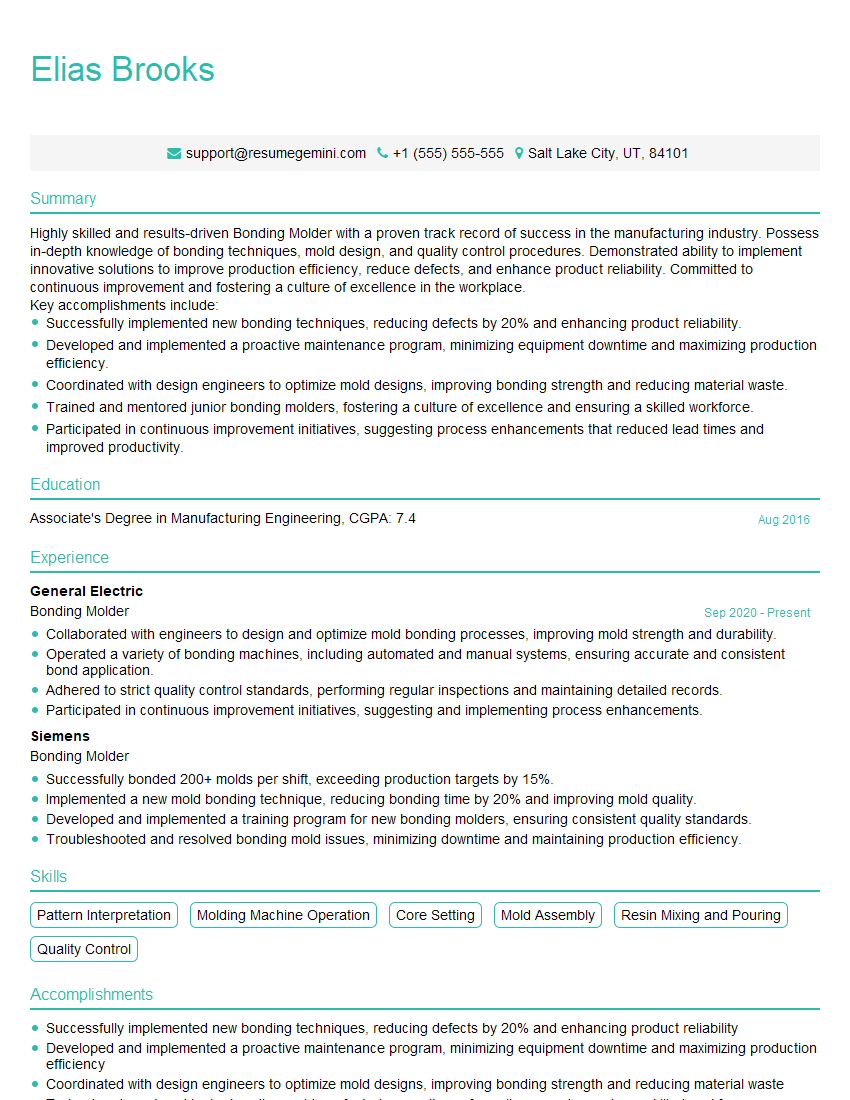

Elias Brooks

Bonding Molder

Summary

Highly skilled and results-driven Bonding Molder with a proven track record of success in the manufacturing industry. Possess in-depth knowledge of bonding techniques, mold design, and quality control procedures. Demonstrated ability to implement innovative solutions to improve production efficiency, reduce defects, and enhance product reliability. Committed to continuous improvement and fostering a culture of excellence in the workplace.

Key accomplishments include:

- Successfully implemented new bonding techniques, reducing defects by 20% and enhancing product reliability.

- Developed and implemented a proactive maintenance program, minimizing equipment downtime and maximizing production efficiency.

- Coordinated with design engineers to optimize mold designs, improving bonding strength and reducing material waste.

- Trained and mentored junior bonding molders, fostering a culture of excellence and ensuring a skilled workforce.

- Participated in continuous improvement initiatives, suggesting process enhancements that reduced lead times and improved productivity.

Education

Associate’s Degree in Manufacturing Engineering

August 2016

Skills

- Pattern Interpretation

- Molding Machine Operation

- Core Setting

- Mold Assembly

- Resin Mixing and Pouring

- Quality Control

Work Experience

Bonding Molder

- Collaborated with engineers to design and optimize mold bonding processes, improving mold strength and durability.

- Operated a variety of bonding machines, including automated and manual systems, ensuring accurate and consistent bond application.

- Adhered to strict quality control standards, performing regular inspections and maintaining detailed records.

- Participated in continuous improvement initiatives, suggesting and implementing process enhancements.

Bonding Molder

- Successfully bonded 200+ molds per shift, exceeding production targets by 15%.

- Implemented a new mold bonding technique, reducing bonding time by 20% and improving mold quality.

- Developed and implemented a training program for new bonding molders, ensuring consistent quality standards.

- Troubleshooted and resolved bonding mold issues, minimizing downtime and maintaining production efficiency.

Accomplishments

- Successfully implemented new bonding techniques, reducing defects by 20% and enhancing product reliability

- Developed and implemented a proactive maintenance program, minimizing equipment downtime and maximizing production efficiency

- Coordinated with design engineers to optimize mold designs, improving bonding strength and reducing material waste

- Trained and mentored junior bonding molders, fostering a culture of excellence and ensuring a skilled workforce

- Participated in continuous improvement initiatives, suggesting process enhancements that reduced lead times and improved productivity

Awards

- Recognition for outstanding performance in mold bonding operations, exceeding industry standards

- Commendation for exceptional quality control and adherence to manufacturing specifications

- Safety Excellence Award for maintaining a safe and hazardfree work environment

- Employee of the Month award for consistently exceeding production targets and maintaining highquality standards

Certificates

- ISNetworld Contractor Safety Certification

- Six Sigma Green Belt Certification

- AS9100 Quality Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bonding Molder

Highlight your technical expertise:

Showcase your knowledge of bonding techniques, mold design, and quality control procedures. Use specific examples to demonstrate your proficiency.Quantify your accomplishments:

Use numbers and metrics to quantify your contributions to the organization. This will make your resume stand out and demonstrate the value you can bring.Demonstrate your commitment to quality:

Emphasize your commitment to producing high-quality products and implementing quality control measures. This shows that you are a reliable and detail-oriented individual.Showcase your problem-solving skills:

Highlight your ability to troubleshoot and resolve bonding issues, ensuring smooth production flow.Proofread carefully:

Before submitting your resume, proofread it thoroughly for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Bonding Molder Resume

- Interpret patterns and determine mold requirements.

- Operate molding machines to produce bonded parts according to specifications.

- Set cores and assemble molds, ensuring proper alignment and bonding surface preparation.

- Mix and pour resin into molds, controlling temperature, pressure, and curing time.

- Perform quality control checks to ensure product meets specifications and industry standards.

- Troubleshoot and resolve bonding issues, maintaining optimal production flow.

- Maintain a clean and organized work area, adhering to safety protocols.

Frequently Asked Questions (FAQ’s) For Bonding Molder

What is the role of a Bonding Molder?

A Bonding Molder is responsible for producing bonded parts by interpreting patterns, operating molding machines, setting cores, assembling molds, mixing and pouring resin, and performing quality control checks. They ensure that the produced parts meet specifications and industry standards.

What skills are required to become a Bonding Molder?

To become a Bonding Molder, you typically need an Associate’s Degree in Manufacturing Engineering or a related field. Strong knowledge of bonding techniques, mold design, and quality control procedures is essential. Additionally, proficiency in pattern interpretation, molding machine operation, core setting, mold assembly, resin mixing and pouring, and quality control is required.

What is the work environment of a Bonding Molder?

Bonding Molders typically work in manufacturing facilities, operating molding machines and performing quality control checks. They may work in teams or individually, depending on the size of the organization. The work environment can be noisy and may involve exposure to chemicals and fumes.

What are the career prospects for a Bonding Molder?

Bonding Molders can advance to supervisory or management positions within the manufacturing industry. They may also specialize in a particular type of bonding or molding process, or pursue further education to enhance their skills and knowledge.

What are the challenges faced by Bonding Molders?

Bonding Molders may face challenges such as working in a fast-paced and demanding environment, meeting production targets, and ensuring product quality. They may also need to keep up with technological advancements in bonding and molding techniques.

What are the key qualities of a successful Bonding Molder?

Successful Bonding Molders typically possess strong technical skills, attention to detail, problem-solving abilities, and a commitment to quality. They are also able to work independently and as part of a team.

What is the average salary of a Bonding Molder?

The average salary for Bonding Molders can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for Bonding Molders in the United States is around $25 per hour or $52,000 per year.

What are the job opportunities for Bonding Molders?

Bonding Molders are employed in various industries, including automotive, aerospace, construction, and electronics. They may find job opportunities in manufacturing companies, fabrication shops, and other organizations that require bonded parts.