Are you a seasoned Edge Gluer seeking a new career path? Discover our professionally built Edge Gluer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

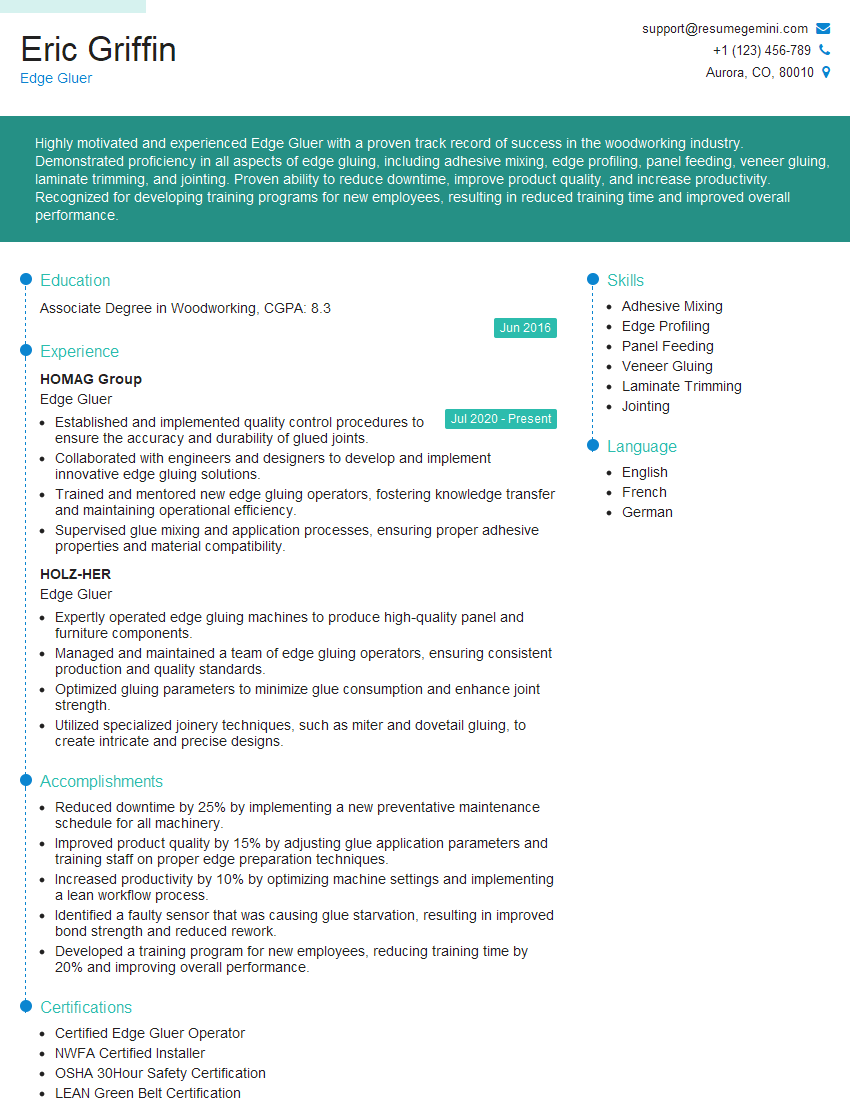

Eric Griffin

Edge Gluer

Summary

Highly motivated and experienced Edge Gluer with a proven track record of success in the woodworking industry. Demonstrated proficiency in all aspects of edge gluing, including adhesive mixing, edge profiling, panel feeding, veneer gluing, laminate trimming, and jointing. Proven ability to reduce downtime, improve product quality, and increase productivity. Recognized for developing training programs for new employees, resulting in reduced training time and improved overall performance.

Education

Associate Degree in Woodworking

June 2016

Skills

- Adhesive Mixing

- Edge Profiling

- Panel Feeding

- Veneer Gluing

- Laminate Trimming

- Jointing

Work Experience

Edge Gluer

- Established and implemented quality control procedures to ensure the accuracy and durability of glued joints.

- Collaborated with engineers and designers to develop and implement innovative edge gluing solutions.

- Trained and mentored new edge gluing operators, fostering knowledge transfer and maintaining operational efficiency.

- Supervised glue mixing and application processes, ensuring proper adhesive properties and material compatibility.

Edge Gluer

- Expertly operated edge gluing machines to produce high-quality panel and furniture components.

- Managed and maintained a team of edge gluing operators, ensuring consistent production and quality standards.

- Optimized gluing parameters to minimize glue consumption and enhance joint strength.

- Utilized specialized joinery techniques, such as miter and dovetail gluing, to create intricate and precise designs.

Accomplishments

- Reduced downtime by 25% by implementing a new preventative maintenance schedule for all machinery.

- Improved product quality by 15% by adjusting glue application parameters and training staff on proper edge preparation techniques.

- Increased productivity by 10% by optimizing machine settings and implementing a lean workflow process.

- Identified a faulty sensor that was causing glue starvation, resulting in improved bond strength and reduced rework.

- Developed a training program for new employees, reducing training time by 20% and improving overall performance.

Certificates

- Certified Edge Gluer Operator

- NWFA Certified Installer

- OSHA 30Hour Safety Certification

- LEAN Green Belt Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Edge Gluer

- Emphasize your experience in all aspects of edge gluing, including adhesive mixing, edge profiling, panel feeding, veneer gluing, laminate trimming, and jointing.

- Highlight your ability to reduce downtime, improve product quality, and increase productivity through the implementation of new processes and techniques.

- Demonstrate your commitment to safety by mentioning your adherence to safety protocols and your ability to maintain a clean and organized work area.

- Showcase your training and development skills by highlighting your role in developing training programs for new employees.

Essential Experience Highlights for a Strong Edge Gluer Resume

- Operate and maintain edge gluing machinery, ensuring optimal performance and minimal downtime.

- Monitor glue application parameters and adjust as needed to achieve desired bond strength and product quality.

- Prepare and feed panels into the edge gluing machine, ensuring proper alignment and positioning.

- Inspect finished products for defects and ensure they meet quality standards.

- Perform preventive maintenance and repairs on edge gluing machinery to minimize downtime.

- Train and supervise new employees on edge gluing procedures and techniques.

- Maintain a clean and organized work area, adhering to safety protocols.

Frequently Asked Questions (FAQ’s) For Edge Gluer

What is the purpose of an edge gluing machine?

An edge gluing machine is used to join the edges of two or more pieces of wood or other materials, creating a strong and durable bond.

What types of materials can be edge glued?

Edge gluing machines can be used to join a variety of materials, including wood, plastic, metal, and glass.

What are the different types of edge gluing machines?

There are two main types of edge gluing machines: manual and automatic. Manual edge gluing machines require the operator to manually feed the materials into the machine and apply the glue. Automatic edge gluing machines do this process automatically, making them more efficient and productive.

What are the benefits of using an edge gluing machine?

Edge gluing machines offer a number of benefits, including: – Increased productivity – Improved product quality – Reduced downtime – Increased safety

What are the key factors to consider when choosing an edge gluing machine?

When choosing an edge gluing machine, there are a number of factors to consider, including: – The type of materials you will be gluing – The volume of materials you will be gluing – The desired level of automation – The budget

How can I maintain my edge gluing machine?

To maintain your edge gluing machine, you should: – Regularly clean the machine – Lubricate the moving parts – Inspect the machine for any signs of wear or damage – Calibrate the machine regularly