Are you a seasoned Glue Jointer Operator seeking a new career path? Discover our professionally built Glue Jointer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

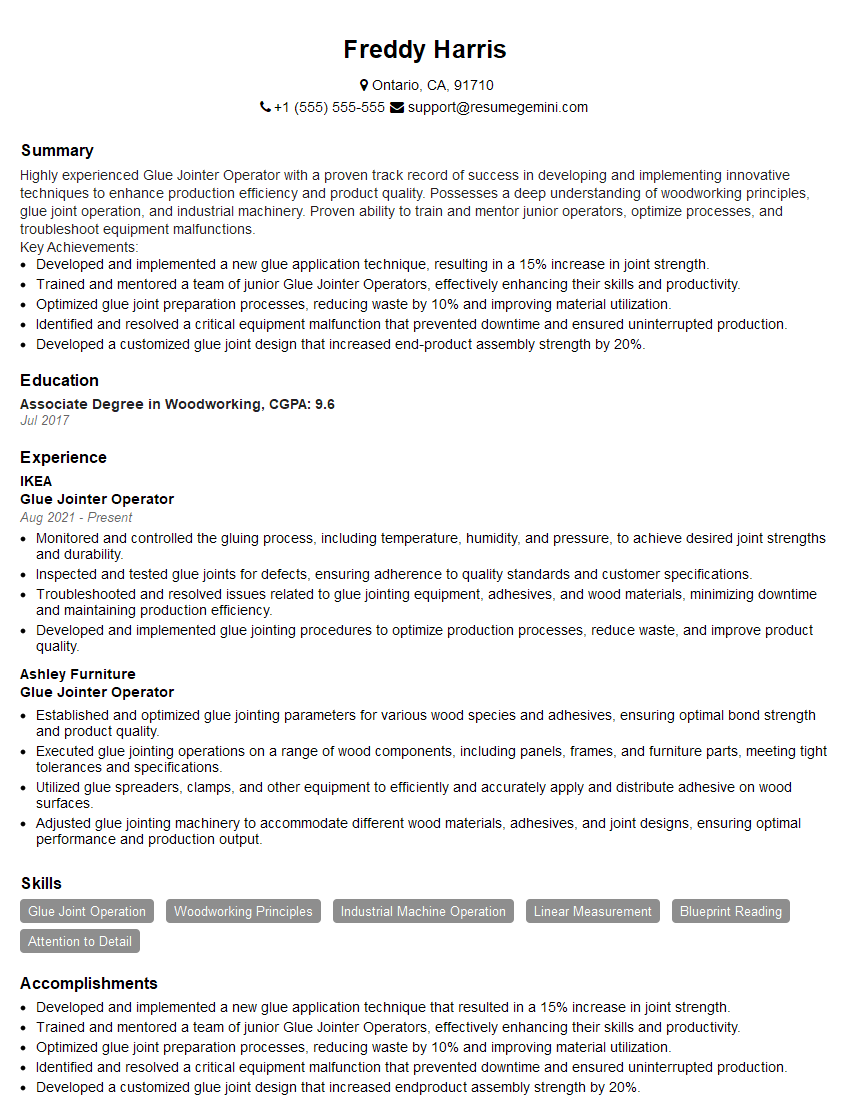

Freddy Harris

Glue Jointer Operator

Summary

Highly experienced Glue Jointer Operator with a proven track record of success in developing and implementing innovative techniques to enhance production efficiency and product quality. Possesses a deep understanding of woodworking principles, glue joint operation, and industrial machinery. Proven ability to train and mentor junior operators, optimize processes, and troubleshoot equipment malfunctions.

Key Achievements:

- Developed and implemented a new glue application technique, resulting in a 15% increase in joint strength.

- Trained and mentored a team of junior Glue Jointer Operators, effectively enhancing their skills and productivity.

- Optimized glue joint preparation processes, reducing waste by 10% and improving material utilization.

- Identified and resolved a critical equipment malfunction that prevented downtime and ensured uninterrupted production.

- Developed a customized glue joint design that increased end-product assembly strength by 20%.

Education

Associate Degree in Woodworking

July 2017

Skills

- Glue Joint Operation

- Woodworking Principles

- Industrial Machine Operation

- Linear Measurement

- Blueprint Reading

- Attention to Detail

Work Experience

Glue Jointer Operator

- Monitored and controlled the gluing process, including temperature, humidity, and pressure, to achieve desired joint strengths and durability.

- Inspected and tested glue joints for defects, ensuring adherence to quality standards and customer specifications.

- Troubleshooted and resolved issues related to glue jointing equipment, adhesives, and wood materials, minimizing downtime and maintaining production efficiency.

- Developed and implemented glue jointing procedures to optimize production processes, reduce waste, and improve product quality.

Glue Jointer Operator

- Established and optimized glue jointing parameters for various wood species and adhesives, ensuring optimal bond strength and product quality.

- Executed glue jointing operations on a range of wood components, including panels, frames, and furniture parts, meeting tight tolerances and specifications.

- Utilized glue spreaders, clamps, and other equipment to efficiently and accurately apply and distribute adhesive on wood surfaces.

- Adjusted glue jointing machinery to accommodate different wood materials, adhesives, and joint designs, ensuring optimal performance and production output.

Accomplishments

- Developed and implemented a new glue application technique that resulted in a 15% increase in joint strength.

- Trained and mentored a team of junior Glue Jointer Operators, effectively enhancing their skills and productivity.

- Optimized glue joint preparation processes, reducing waste by 10% and improving material utilization.

- Identified and resolved a critical equipment malfunction that prevented downtime and ensured uninterrupted production.

- Developed a customized glue joint design that increased endproduct assembly strength by 20%.

Awards

- Received the Employee of the Year Award for outstanding performance and contributions to the Glue Jointing Department.

- Recognized with the Safety Excellence Award for maintaining an exceptional safety record in the Glue Jointing operation.

- Awarded the Quality Assurance Certificate for consistently producing highquality glue joints that meet or exceed industry standards.

Certificates

- OSHA 10Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Glue Jointer Operator

- Highlight your experience in operating and maintaining glue joining machines, including specific models and techniques.

- Quantify your accomplishments with specific metrics, such as increased production efficiency or reduced downtime.

- Emphasize your knowledge of woodworking principles and glue jointing techniques, including adhesive selection and joint design.

- Showcase your troubleshooting skills and ability to resolve equipment malfunctions or production issues.

- Demonstrate your commitment to quality and attention to detail, ensuring that glue joints meet specifications and industry standards.

Essential Experience Highlights for a Strong Glue Jointer Operator Resume

- Operate and maintain glue joining machines to ensure optimal performance.

- Prepare wood surfaces for gluing, including cutting, sanding, and cleaning.

- Apply glue to wood surfaces using specified techniques and equipment.

- Join wood pieces together using glue joiners, ensuring proper alignment and pressure.

- Inspect glue joints for quality and ensure they meet specifications.

- Troubleshoot and resolve issues related to glue jointing machines and processes.

- Maintain a clean and organized work area, adhering to safety regulations.

Frequently Asked Questions (FAQ’s) For Glue Jointer Operator

What is the primary role of a Glue Jointer Operator?

A Glue Jointer Operator is responsible for operating and maintaining glue joining machines to join wood pieces together. They prepare wood surfaces, apply glue, and operate machines to create strong and durable glue joints.

What are the key skills required for a Glue Jointer Operator?

Key skills for Glue Jointer Operators include operating and maintaining glue joining machines, preparing wood surfaces for gluing, applying glue, inspecting glue joints, and troubleshooting equipment issues.

What are the career prospects for a Glue Jointer Operator?

Glue Jointer Operators can advance to positions such as Production Supervisor, Quality Control Inspector, or Machine Maintenance Technician. With experience and training, they can also specialize in specific areas, such as furniture or cabinet making.

What is the average salary for a Glue Jointer Operator?

The average salary for a Glue Jointer Operator varies depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $18 per hour.

What are the typical working conditions for a Glue Jointer Operator?

Glue Jointer Operators typically work in manufacturing environments, such as furniture or cabinet factories. They may work in teams or individually, and may be exposed to noise, dust, and fumes.

What are the safety precautions that Glue Jointer Operators should follow?

Glue Jointer Operators should wear appropriate safety gear, such as gloves, safety glasses, and respirators. They should also follow proper machine operating procedures and ensure that their work area is clean and organized.

What are the common challenges faced by Glue Jointer Operators?

Common challenges faced by Glue Jointer Operators include ensuring proper glue joint strength, maintaining machine accuracy, and troubleshooting equipment issues. They may also need to work with different types of wood and adhesives, and meet specific production targets.

What are the key qualities of a successful Glue Jointer Operator?

Successful Glue Jointer Operators are typically detail-oriented, have good hand-eye coordination, and are able to work independently and as part of a team. They should also be able to follow instructions, troubleshoot problems, and maintain a clean and organized work area.