Are you a seasoned Ammonia Refrigeration Worker seeking a new career path? Discover our professionally built Ammonia Refrigeration Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

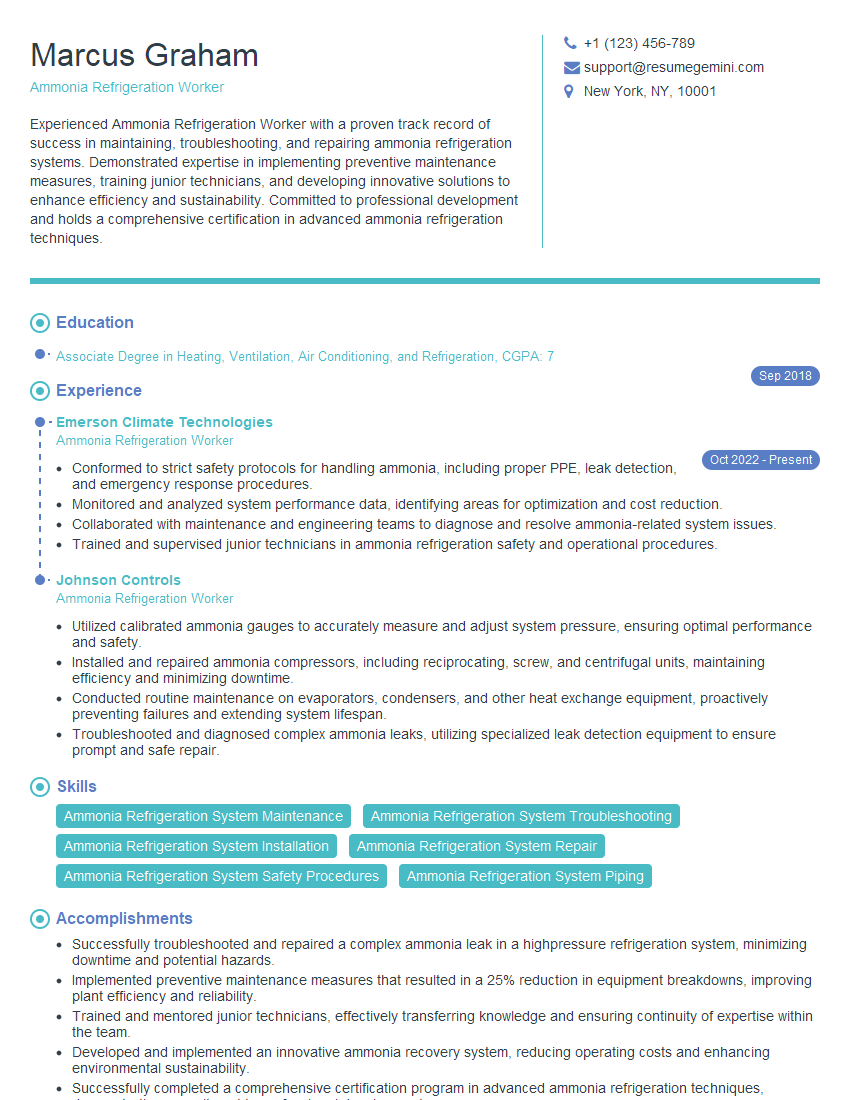

Marcus Graham

Ammonia Refrigeration Worker

Summary

Experienced Ammonia Refrigeration Worker with a proven track record of success in maintaining, troubleshooting, and repairing ammonia refrigeration systems. Demonstrated expertise in implementing preventive maintenance measures, training junior technicians, and developing innovative solutions to enhance efficiency and sustainability. Committed to professional development and holds a comprehensive certification in advanced ammonia refrigeration techniques.

Education

Associate Degree in Heating, Ventilation, Air Conditioning, and Refrigeration

September 2018

Skills

- Ammonia Refrigeration System Maintenance

- Ammonia Refrigeration System Troubleshooting

- Ammonia Refrigeration System Installation

- Ammonia Refrigeration System Repair

- Ammonia Refrigeration System Safety Procedures

- Ammonia Refrigeration System Piping

Work Experience

Ammonia Refrigeration Worker

- Conformed to strict safety protocols for handling ammonia, including proper PPE, leak detection, and emergency response procedures.

- Monitored and analyzed system performance data, identifying areas for optimization and cost reduction.

- Collaborated with maintenance and engineering teams to diagnose and resolve ammonia-related system issues.

- Trained and supervised junior technicians in ammonia refrigeration safety and operational procedures.

Ammonia Refrigeration Worker

- Utilized calibrated ammonia gauges to accurately measure and adjust system pressure, ensuring optimal performance and safety.

- Installed and repaired ammonia compressors, including reciprocating, screw, and centrifugal units, maintaining efficiency and minimizing downtime.

- Conducted routine maintenance on evaporators, condensers, and other heat exchange equipment, proactively preventing failures and extending system lifespan.

- Troubleshooted and diagnosed complex ammonia leaks, utilizing specialized leak detection equipment to ensure prompt and safe repair.

Accomplishments

- Successfully troubleshooted and repaired a complex ammonia leak in a highpressure refrigeration system, minimizing downtime and potential hazards.

- Implemented preventive maintenance measures that resulted in a 25% reduction in equipment breakdowns, improving plant efficiency and reliability.

- Trained and mentored junior technicians, effectively transferring knowledge and ensuring continuity of expertise within the team.

- Developed and implemented an innovative ammonia recovery system, reducing operating costs and enhancing environmental sustainability.

- Successfully completed a comprehensive certification program in advanced ammonia refrigeration techniques, demonstrating commitment to professional development.

Awards

- Recipient of the Excellence in Ammonia Refrigeration Safety award for demonstrating exceptional adherence to safety protocols and procedures.

- Honored with the Refrigeration Technician of the Year award for consistently exceeding performance standards and delivering exceptional customer service.

- Received the Safety Superstar award in recognition of unwavering commitment to workplace safety, contributing to a zeroaccident record.

- Recognized with the Team Player of the Year award for actively collaborating with colleagues and fostering a positive and supportive work environment.

Certificates

- EPA 608 Universal Certification

- RSES Certified Refrigeration Technician

- National Institute for Certification in Engineering Technologies (NICET) Level III Certification in Refrigeration

- American Society of Heating, Refrigerating and AirConditioning Engineers (ASHRAE) Member

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ammonia Refrigeration Worker

- Highlight your experience and expertise in maintaining and troubleshooting ammonia refrigeration systems.

- Quantify your accomplishments with specific metrics, such as reduced downtime, increased efficiency, and cost savings.

- Emphasize your commitment to safety and adherence to industry regulations.

- Showcase your ability to work independently and as part of a team.

- Tailor your resume to each job description, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Ammonia Refrigeration Worker Resume

- Maintain and repair ammonia refrigeration systems, including compressors, condensers, evaporators, and piping

- Troubleshoot and diagnose malfunctions, identify root causes, and implement effective solutions

- Perform routine maintenance tasks, such as leak detection, system cleaning, and component replacement

- Develop and implement preventive maintenance plans to minimize downtime and extend equipment life

- Train and mentor junior technicians, ensuring knowledge transfer and maintaining team expertise

- Collaborate with engineers and other technical staff to optimize system performance and efficiency

- Adhere to all safety protocols and regulations related to ammonia refrigeration systems

Frequently Asked Questions (FAQ’s) For Ammonia Refrigeration Worker

What is the role of an Ammonia Refrigeration Worker?

An Ammonia Refrigeration Worker is responsible for maintaining, troubleshooting, and repairing ammonia refrigeration systems. They play a crucial role in ensuring the safe, efficient, and reliable operation of these systems in various industries, including food processing, manufacturing, and healthcare.

What qualifications are required to become an Ammonia Refrigeration Worker?

Typically, an Ammonia Refrigeration Worker requires an Associate Degree in Heating, Ventilation, Air Conditioning, and Refrigeration (HVACR) or a related field. They also need to have a thorough understanding of refrigeration principles, ammonia properties, and safety protocols.

What are the key skills and responsibilities of an Ammonia Refrigeration Worker?

Key skills include maintenance, troubleshooting, repair, and installation of ammonia refrigeration systems. Responsibilities involve adhering to safety regulations, performing preventive maintenance, and training junior technicians.

What is the job outlook for Ammonia Refrigeration Workers?

The job outlook for Ammonia Refrigeration Workers is expected to be favorable in the coming years due to the increasing demand for skilled technicians in the refrigeration industry. The growing emphasis on energy efficiency and environmental sustainability is also driving the demand for workers with expertise in ammonia refrigeration systems.

How can I advance my career as an Ammonia Refrigeration Worker?

To advance your career, consider obtaining industry certifications, such as the Certified Ammonia Refrigeration Technician (CART) certification. Additionally, staying updated with the latest technologies and industry best practices through continuing education and professional development opportunities is essential.

What are the safety precautions that Ammonia Refrigeration Workers must follow?

Ammonia Refrigeration Workers must follow strict safety protocols due to the hazardous nature of ammonia. These precautions include wearing appropriate personal protective equipment (PPE), adhering to lockout/tagout procedures, and being aware of potential hazards and emergency response measures.

What are the typical working conditions for Ammonia Refrigeration Workers?

Ammonia Refrigeration Workers typically work in industrial settings, such as manufacturing plants, food processing facilities, and cold storage warehouses. They may work in various environments, including cold rooms, mechanical rooms, and outdoor areas. The work can be physically demanding and may involve exposure to noise, vibration, and chemicals.