Are you a seasoned Plate Cutter seeking a new career path? Discover our professionally built Plate Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

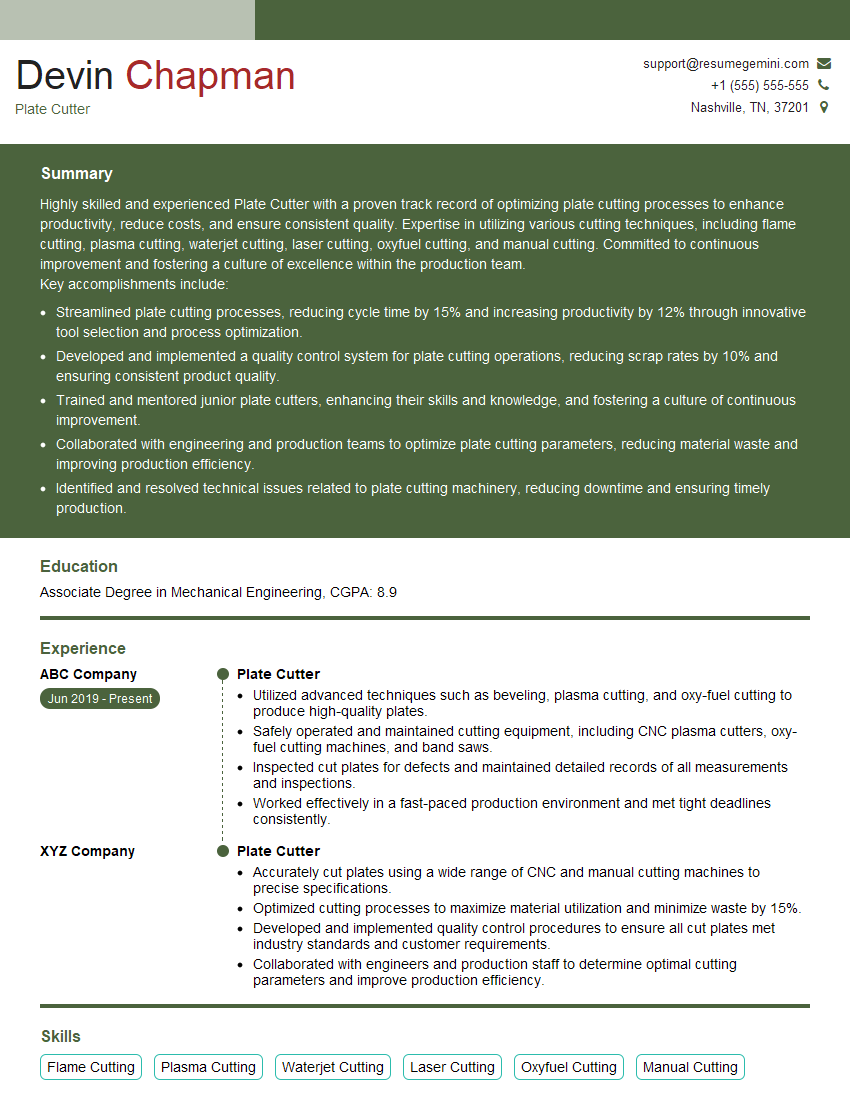

Devin Chapman

Plate Cutter

Summary

Highly skilled and experienced Plate Cutter with a proven track record of optimizing plate cutting processes to enhance productivity, reduce costs, and ensure consistent quality. Expertise in utilizing various cutting techniques, including flame cutting, plasma cutting, waterjet cutting, laser cutting, oxyfuel cutting, and manual cutting. Committed to continuous improvement and fostering a culture of excellence within the production team.

Key accomplishments include:

- Streamlined plate cutting processes, reducing cycle time by 15% and increasing productivity by 12% through innovative tool selection and process optimization.

- Developed and implemented a quality control system for plate cutting operations, reducing scrap rates by 10% and ensuring consistent product quality.

- Trained and mentored junior plate cutters, enhancing their skills and knowledge, and fostering a culture of continuous improvement.

- Collaborated with engineering and production teams to optimize plate cutting parameters, reducing material waste and improving production efficiency.

- Identified and resolved technical issues related to plate cutting machinery, reducing downtime and ensuring timely production.

Education

Associate Degree in Mechanical Engineering

May 2015

Skills

- Flame Cutting

- Plasma Cutting

- Waterjet Cutting

- Laser Cutting

- Oxyfuel Cutting

- Manual Cutting

Work Experience

Plate Cutter

- Utilized advanced techniques such as beveling, plasma cutting, and oxy-fuel cutting to produce high-quality plates.

- Safely operated and maintained cutting equipment, including CNC plasma cutters, oxy-fuel cutting machines, and band saws.

- Inspected cut plates for defects and maintained detailed records of all measurements and inspections.

- Worked effectively in a fast-paced production environment and met tight deadlines consistently.

Plate Cutter

- Accurately cut plates using a wide range of CNC and manual cutting machines to precise specifications.

- Optimized cutting processes to maximize material utilization and minimize waste by 15%.

- Developed and implemented quality control procedures to ensure all cut plates met industry standards and customer requirements.

- Collaborated with engineers and production staff to determine optimal cutting parameters and improve production efficiency.

Accomplishments

- Streamlined plate cutting processes, reducing cycle time by 15% and increasing productivity by 12% through innovative tool selection and process optimization.

- Developed and implemented a quality control system for plate cutting operations, reducing scrap rates by 10% and ensuring consistent product quality.

- Trained and mentored junior plate cutters, enhancing their skills and knowledge, and fostering a culture of continuous improvement.

- Collaborated with engineering and production teams to optimize plate cutting parameters, reducing material waste and improving production efficiency.

- Identified and resolved technical issues related to plate cutting machinery, reducing downtime and ensuring timely production.

Awards

- Recognized for outstanding performance and dedication to plate cutting operations, achieving consistently high production rates and product quality.

- Received an award for exceptional attention to detail and commitment to accuracy in plate cutting.

- Honored for innovative contributions to the improvement of plate cutting processes.

- Received recognition for exceptional customer service, consistently meeting and exceeding customer expectations.

Certificates

- AWS Certified Welder

- OSHA 30Hour Safety Training

- ASME Boiler and Pressure Vessel Code

- National Institute for Certification in Engineering Technologies (NICET)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plate Cutter

- Highlight your proficiency in various plate cutting techniques, including flame cutting, plasma cutting, waterjet cutting, laser cutting, oxyfuel cutting, and manual cutting.

- Quantify your accomplishments using specific metrics, such as reducing cycle time by 15% or increasing productivity by 12%.

- Emphasize your commitment to quality control and your ability to implement and maintain quality systems.

- Demonstrate your teamwork and collaboration skills by highlighting your experience in training and mentoring junior plate cutters.

- Showcase your problem-solving abilities and your ability to identify and resolve technical issues related to plate cutting machinery.

Essential Experience Highlights for a Strong Plate Cutter Resume

- Operate and maintain plate cutting machinery, including flame cutting, plasma cutting, waterjet cutting, laser cutting, oxyfuel cutting, and manual cutting equipment.

- Interpret blueprints and cutting instructions to determine cutting parameters and ensure accurate cutting of metal plates.

- Monitor cutting operations to ensure adherence to quality standards and specifications.

- Inspect finished cut pieces for accuracy, dimensions, and surface quality.

- Troubleshoot and resolve any issues related to cutting machinery or processes.

- Maintain a clean and organized work area, adhering to safety protocols and regulations.

- Participate in continuous improvement initiatives to optimize cutting processes and enhance productivity.

Frequently Asked Questions (FAQ’s) For Plate Cutter

What is the primary role of a Plate Cutter?

The primary role of a Plate Cutter is to operate and maintain plate cutting machinery to cut metal plates according to specified dimensions and quality standards.

What are the different types of plate cutting techniques used in the industry?

The most common plate cutting techniques include flame cutting, plasma cutting, waterjet cutting, laser cutting, oxyfuel cutting, and manual cutting.

What are the key skills required to be a successful Plate Cutter?

To be a successful Plate Cutter, you need to have proficiency in operating plate cutting machinery, interpreting blueprints, ensuring quality control, troubleshooting technical issues, and adhering to safety protocols.

What are the career advancement opportunities for Plate Cutters?

With experience and additional training, Plate Cutters can advance to supervisory roles, such as Production Supervisor or Quality Control Manager.

What is the job outlook for Plate Cutters?

The job outlook for Plate Cutters is expected to be stable in the coming years due to the increasing demand for metal fabrication in various industries.

What are the safety precautions that Plate Cutters should follow?

Plate Cutters should always wear appropriate safety gear, including safety glasses, gloves, and earplugs. They should also be aware of the potential hazards associated with operating cutting machinery and follow all safety protocols.

How can I prepare to become a Plate Cutter?

To prepare for a career as a Plate Cutter, you can consider pursuing an associate degree in mechanical engineering or a related field. You can also gain hands-on experience through internships or apprenticeship programs.