Are you a seasoned Plastic Injection Mold Maker seeking a new career path? Discover our professionally built Plastic Injection Mold Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

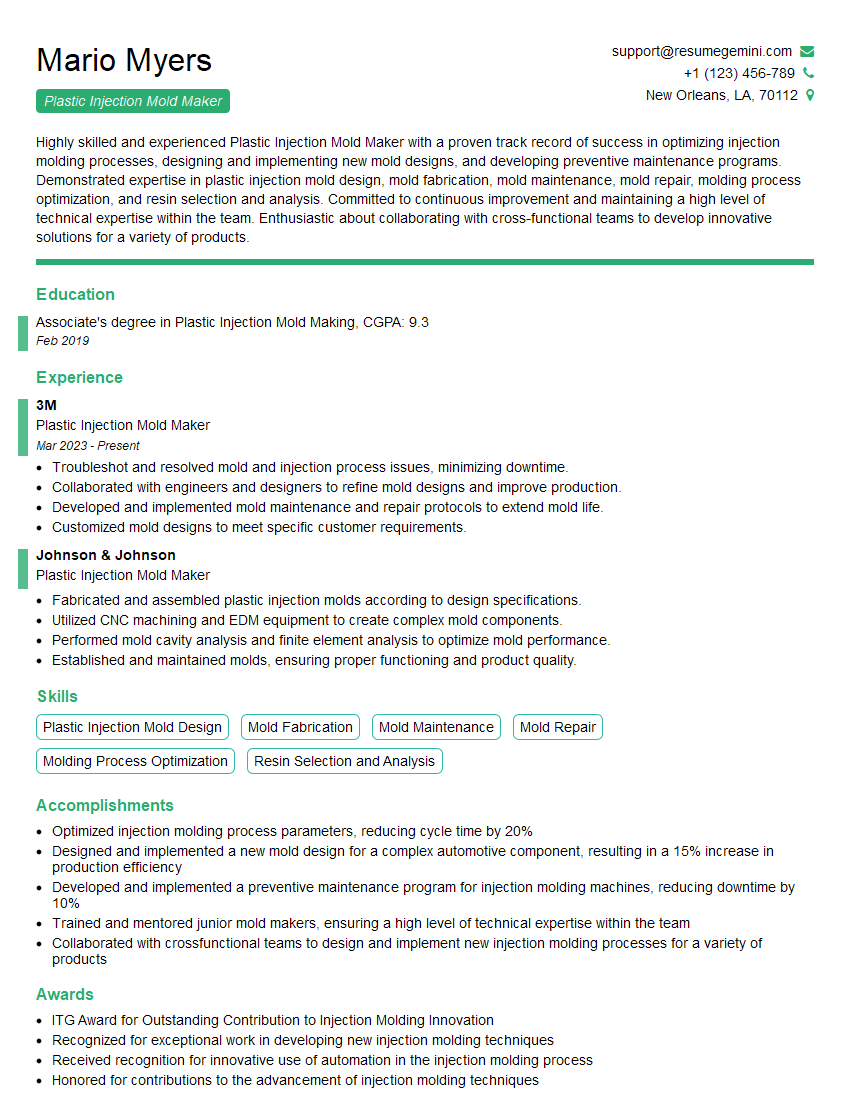

Mario Myers

Plastic Injection Mold Maker

Summary

Highly skilled and experienced Plastic Injection Mold Maker with a proven track record of success in optimizing injection molding processes, designing and implementing new mold designs, and developing preventive maintenance programs. Demonstrated expertise in plastic injection mold design, mold fabrication, mold maintenance, mold repair, molding process optimization, and resin selection and analysis. Committed to continuous improvement and maintaining a high level of technical expertise within the team. Enthusiastic about collaborating with cross-functional teams to develop innovative solutions for a variety of products.

Education

Associate’s degree in Plastic Injection Mold Making

February 2019

Skills

- Plastic Injection Mold Design

- Mold Fabrication

- Mold Maintenance

- Mold Repair

- Molding Process Optimization

- Resin Selection and Analysis

Work Experience

Plastic Injection Mold Maker

- Troubleshot and resolved mold and injection process issues, minimizing downtime.

- Collaborated with engineers and designers to refine mold designs and improve production.

- Developed and implemented mold maintenance and repair protocols to extend mold life.

- Customized mold designs to meet specific customer requirements.

Plastic Injection Mold Maker

- Fabricated and assembled plastic injection molds according to design specifications.

- Utilized CNC machining and EDM equipment to create complex mold components.

- Performed mold cavity analysis and finite element analysis to optimize mold performance.

- Established and maintained molds, ensuring proper functioning and product quality.

Accomplishments

- Optimized injection molding process parameters, reducing cycle time by 20%

- Designed and implemented a new mold design for a complex automotive component, resulting in a 15% increase in production efficiency

- Developed and implemented a preventive maintenance program for injection molding machines, reducing downtime by 10%

- Trained and mentored junior mold makers, ensuring a high level of technical expertise within the team

- Collaborated with crossfunctional teams to design and implement new injection molding processes for a variety of products

Awards

- ITG Award for Outstanding Contribution to Injection Molding Innovation

- Recognized for exceptional work in developing new injection molding techniques

- Received recognition for innovative use of automation in the injection molding process

- Honored for contributions to the advancement of injection molding techniques

Certificates

- Certified Plastic Injection Mold Maker (CPMM)

- Certified Injection Mold Designer (CIMD)

- Certified Mold Maker Journeyman (CMMJ)

- Certified Mold Repair Technician (CMRT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Injection Mold Maker

- Highlight your technical skills and expertise in plastic injection mold design, fabrication, and maintenance.

- Quantify your accomplishments with specific metrics, such as percentage improvements in production efficiency or cycle time reduction.

- Showcase your problem-solving abilities and innovative approach to mold design and process optimization.

- Emphasize your commitment to teamwork and collaboration, as well as your ability to train and mentor others.

Essential Experience Highlights for a Strong Plastic Injection Mold Maker Resume

- Design and develop plastic injection molds for a variety of products, ensuring optimal production efficiency and product quality.

- Fabricate and maintain injection molds, utilizing specialized equipment and techniques to achieve precise tolerances.

- Optimize injection molding process parameters to minimize cycle time, reduce waste, and improve overall production efficiency.

- Conduct preventive maintenance on injection molding machines to minimize downtime and ensure optimal performance.

- Train and mentor junior mold makers, fostering a culture of technical excellence within the team.

- Collaborate with cross-functional teams, including engineers, designers, and production personnel, to develop and implement new injection molding processes.

- Stay abreast of industry best practices and emerging technologies in plastic injection molding.

Frequently Asked Questions (FAQ’s) For Plastic Injection Mold Maker

What are the key skills required to be a successful Plastic Injection Mold Maker?

To be a successful Plastic Injection Mold Maker, you need a strong foundation in plastic injection mold design, fabrication, maintenance, and repair. You should also be proficient in molding process optimization, resin selection and analysis, and have a thorough understanding of industry best practices and emerging technologies.

What are the career prospects for Plastic Injection Mold Makers?

Plastic Injection Mold Makers are in high demand due to the growing use of plastic products in various industries. With experience and expertise, you can advance to supervisory or management roles, specializing in mold design, process engineering, or quality control.

What are the educational requirements to become a Plastic Injection Mold Maker?

Typically, an Associate’s degree in Plastic Injection Mold Making or a related field is required to enter this profession. Some employers may also consider candidates with a high school diploma and relevant work experience.

What is the work environment like for Plastic Injection Mold Makers?

Plastic Injection Mold Makers typically work in manufacturing facilities, operating and maintaining injection molding machines. The work environment can be noisy and involve exposure to chemicals and??. However, with proper safety precautions and protective gear, it is a safe and rewarding profession.

What are the salary expectations for Plastic Injection Mold Makers?

The salary expectations for Plastic Injection Mold Makers vary depending on experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Molding and Casting Workers was $46,900 in May 2021.

What are the challenges faced by Plastic Injection Mold Makers?

Plastic Injection Mold Makers may face challenges such as working with tight tolerances, meeting production deadlines, and ensuring the quality of plastic products. They also need to stay updated with the latest technologies and industry best practices to remain competitive.