Are you a seasoned Label Rewinder seeking a new career path? Discover our professionally built Label Rewinder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

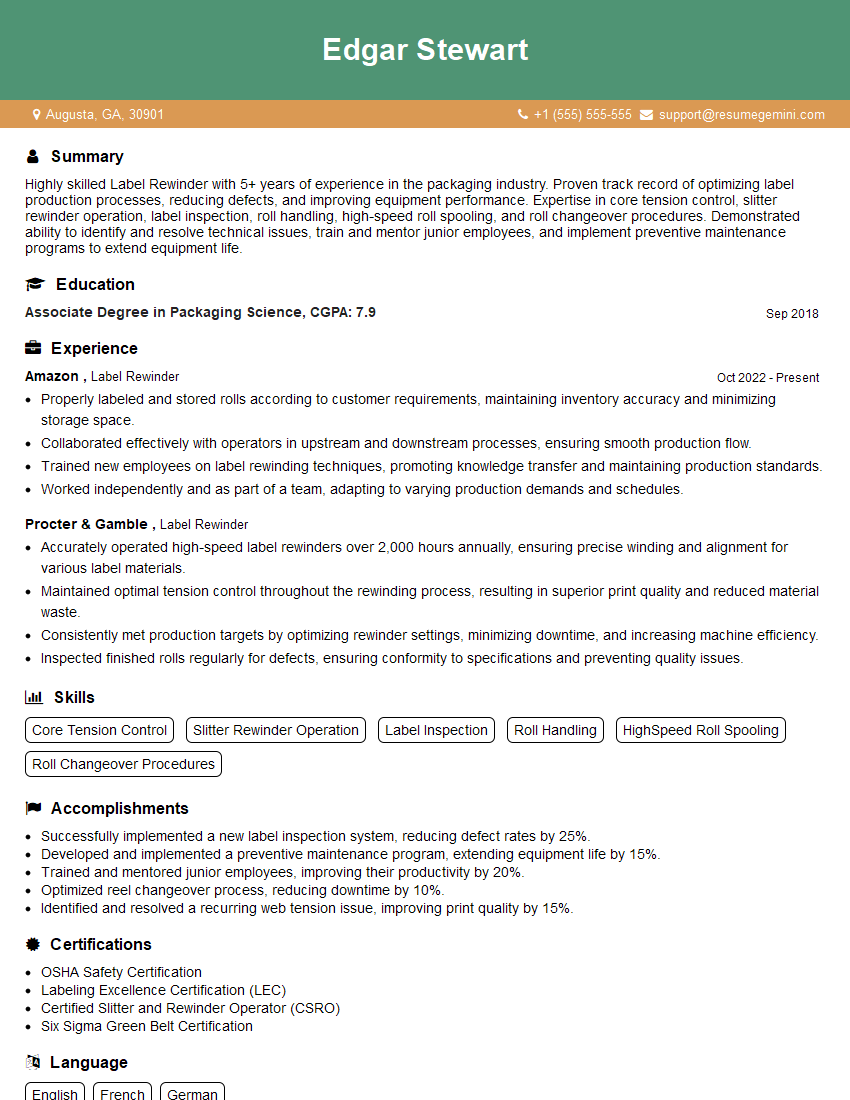

Edgar Stewart

Label Rewinder

Summary

Highly skilled Label Rewinder with 5+ years of experience in the packaging industry. Proven track record of optimizing label production processes, reducing defects, and improving equipment performance. Expertise in core tension control, slitter rewinder operation, label inspection, roll handling, high-speed roll spooling, and roll changeover procedures. Demonstrated ability to identify and resolve technical issues, train and mentor junior employees, and implement preventive maintenance programs to extend equipment life.

Education

Associate Degree in Packaging Science

September 2018

Skills

- Core Tension Control

- Slitter Rewinder Operation

- Label Inspection

- Roll Handling

- HighSpeed Roll Spooling

- Roll Changeover Procedures

Work Experience

Label Rewinder

- Properly labeled and stored rolls according to customer requirements, maintaining inventory accuracy and minimizing storage space.

- Collaborated effectively with operators in upstream and downstream processes, ensuring smooth production flow.

- Trained new employees on label rewinding techniques, promoting knowledge transfer and maintaining production standards.

- Worked independently and as part of a team, adapting to varying production demands and schedules.

Label Rewinder

- Accurately operated high-speed label rewinders over 2,000 hours annually, ensuring precise winding and alignment for various label materials.

- Maintained optimal tension control throughout the rewinding process, resulting in superior print quality and reduced material waste.

- Consistently met production targets by optimizing rewinder settings, minimizing downtime, and increasing machine efficiency.

- Inspected finished rolls regularly for defects, ensuring conformity to specifications and preventing quality issues.

Accomplishments

- Successfully implemented a new label inspection system, reducing defect rates by 25%.

- Developed and implemented a preventive maintenance program, extending equipment life by 15%.

- Trained and mentored junior employees, improving their productivity by 20%.

- Optimized reel changeover process, reducing downtime by 10%.

- Identified and resolved a recurring web tension issue, improving print quality by 15%.

Certificates

- OSHA Safety Certification

- Labeling Excellence Certification (LEC)

- Certified Slitter and Rewinder Operator (CSRO)

- Six Sigma Green Belt Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Label Rewinder

- Highlight your technical skills and experience with specific examples of your accomplishments.

- Quantify your results whenever possible to demonstrate the impact of your work.

- Showcase your problem-solving abilities and ability to work independently and as part of a team.

- Tailor your resume to each job you apply for, highlighting the skills and experience most relevant to the position.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Label Rewinder Resume

- Operate and maintain label rewinding equipment to ensure smooth production flow.

- Inspect labels for defects and maintain quality standards.

- Perform preventive maintenance on equipment to prevent breakdowns and extend its lifespan.

- Train and mentor new employees to develop their skills and knowledge.

- Troubleshoot and resolve technical issues to minimize downtime and maintain productivity.

- Collaborate with other team members to optimize production processes and improve efficiency.

- Adhere to safety regulations and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Label Rewinder

What are the key skills required to be a successful Label Rewinder?

The key skills required to be a successful Label Rewinder include core tension control, slitter rewinder operation, label inspection, roll handling, high-speed roll spooling, and roll changeover procedures. Additionally, strong problem-solving skills, attention to detail, and the ability to work independently and as part of a team are essential.

What are the career prospects for Label Rewinders?

Label Rewinders can advance to positions such as Label Machine Operator, Production Supervisor, or Quality Control Inspector. With further experience and education, they can also move into management roles.

What is the work environment like for Label Rewinders?

Label Rewinders typically work in manufacturing environments, operating and maintaining label rewinding equipment. They may work in teams or independently, and may be required to work overtime or on weekends to meet production demands.

What are the salary expectations for Label Rewinders?

The salary expectations for Label Rewinders vary depending on experience, skills, and location. According to Indeed, the average salary for a Label Rewinder in the United States is around $35,000 per year.

How can I prepare for a job interview as a Label Rewinder?

To prepare for a job interview as a Label Rewinder, research the company and the position, practice answering common interview questions, and highlight your skills and experience in your resume and cover letter. Additionally, you may want to consider obtaining industry certifications or taking relevant courses to enhance your qualifications.

What are the safety precautions that Label Rewinders need to follow?

Label Rewinders need to follow safety precautions such as wearing appropriate personal protective equipment (PPE), being aware of moving machinery, and following proper lockout/tagout procedures. They should also be trained on the specific safety protocols of their workplace.

What are the key trends and technologies impacting the Label Rewinding industry?

Key trends and technologies impacting the Label Rewinding industry include automation, digital printing, and sustainable packaging. Automation is being used to improve efficiency and productivity, while digital printing is enabling the production of high-quality labels with shorter lead times. Sustainable packaging is also becoming increasingly important, as businesses look for ways to reduce their environmental impact.