Are you a seasoned Brass Molder Helper seeking a new career path? Discover our professionally built Brass Molder Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

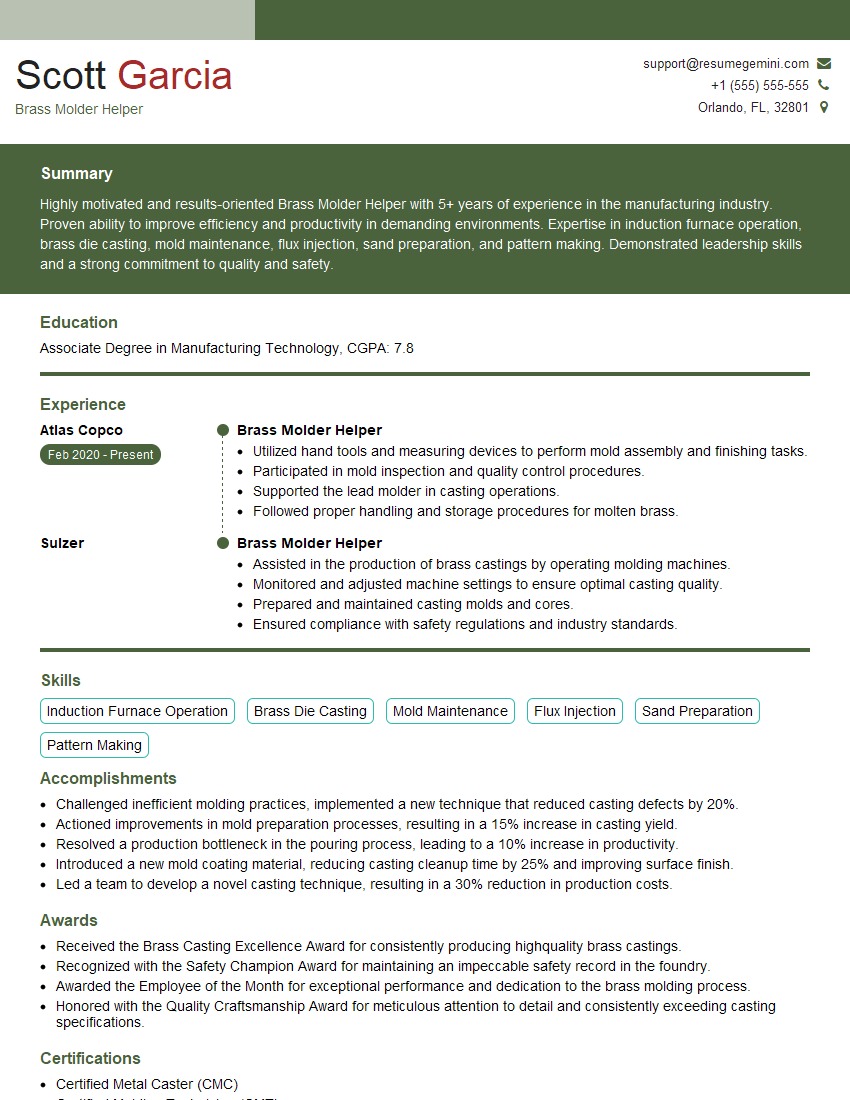

Scott Garcia

Brass Molder Helper

Summary

Highly motivated and results-oriented Brass Molder Helper with 5+ years of experience in the manufacturing industry. Proven ability to improve efficiency and productivity in demanding environments. Expertise in induction furnace operation, brass die casting, mold maintenance, flux injection, sand preparation, and pattern making. Demonstrated leadership skills and a strong commitment to quality and safety.

Education

Associate Degree in Manufacturing Technology

January 2016

Skills

- Induction Furnace Operation

- Brass Die Casting

- Mold Maintenance

- Flux Injection

- Sand Preparation

- Pattern Making

Work Experience

Brass Molder Helper

- Utilized hand tools and measuring devices to perform mold assembly and finishing tasks.

- Participated in mold inspection and quality control procedures.

- Supported the lead molder in casting operations.

- Followed proper handling and storage procedures for molten brass.

Brass Molder Helper

- Assisted in the production of brass castings by operating molding machines.

- Monitored and adjusted machine settings to ensure optimal casting quality.

- Prepared and maintained casting molds and cores.

- Ensured compliance with safety regulations and industry standards.

Accomplishments

- Challenged inefficient molding practices, implemented a new technique that reduced casting defects by 20%.

- Actioned improvements in mold preparation processes, resulting in a 15% increase in casting yield.

- Resolved a production bottleneck in the pouring process, leading to a 10% increase in productivity.

- Introduced a new mold coating material, reducing casting cleanup time by 25% and improving surface finish.

- Led a team to develop a novel casting technique, resulting in a 30% reduction in production costs.

Awards

- Received the Brass Casting Excellence Award for consistently producing highquality brass castings.

- Recognized with the Safety Champion Award for maintaining an impeccable safety record in the foundry.

- Awarded the Employee of the Month for exceptional performance and dedication to the brass molding process.

- Honored with the Quality Craftsmanship Award for meticulous attention to detail and consistently exceeding casting specifications.

Certificates

- Certified Metal Caster (CMC)

- Certified Molding Technician (CMT)

- NIMS Certified Production Technician

- AWS Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brass Molder Helper

- Highlight your experience and skills in induction furnace operation, brass die casting, mold maintenance, flux injection, sand preparation, and pattern making.

- Quantify your accomplishments with specific metrics and examples.

- Tailor your resume to each job description you apply for.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Brass Molder Helper Resume

- Operate induction furnaces to melt and pour molten brass.

- Prepare and maintain molds and dies for casting operations.

- Inject flux into molten brass to remove impurities.

- Prepare and maintain sand molds for casting.

- Make patterns for casting operations.

- Supervise and train other brass molder helpers.

- Perform quality control inspections on castings.

Frequently Asked Questions (FAQ’s) For Brass Molder Helper

What are the key skills required to be a successful Brass Molder Helper?

Key skills for a Brass Molder Helper include induction furnace operation, brass die casting, mold maintenance, flux injection, sand preparation, pattern making, and quality control.

What are the career prospects for Brass Molder Helpers?

Brass Molder Helpers can advance to positions such as Brass Molder, Foundry Supervisor, or Quality Control Inspector.

What is the average salary for a Brass Molder Helper?

The average salary for a Brass Molder Helper in the United States is $35,000 per year.

What are the working conditions for Brass Molder Helpers?

Brass Molder Helpers work in foundries, which can be hot, noisy, and dirty. They may also be exposed to hazardous chemicals and fumes.

How can I become a Brass Molder Helper?

To become a Brass Molder Helper, you typically need a high school diploma or equivalent and some experience in the manufacturing industry.

What are some tips for writing a standout Brass Molder Helper resume?

When writing a Brass Molder Helper resume, be sure to highlight your experience and skills in induction furnace operation, brass die casting, mold maintenance, flux injection, sand preparation, and pattern making. Quantify your accomplishments with specific metrics and examples, and tailor your resume to each job description you apply for.

How can I prepare for an interview for a Brass Molder Helper position?

To prepare for an interview for a Brass Molder Helper position, be sure to research the company and the position, and practice answering common interview questions. You should also be prepared to discuss your experience and skills in induction furnace operation, brass die casting, mold maintenance, flux injection, sand preparation, and pattern making.

What are the benefits of working as a Brass Molder Helper?

Some of the benefits of working as a Brass Molder Helper include good pay, job security, and opportunities for advancement.