Are you a seasoned Coppersmith Helper seeking a new career path? Discover our professionally built Coppersmith Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

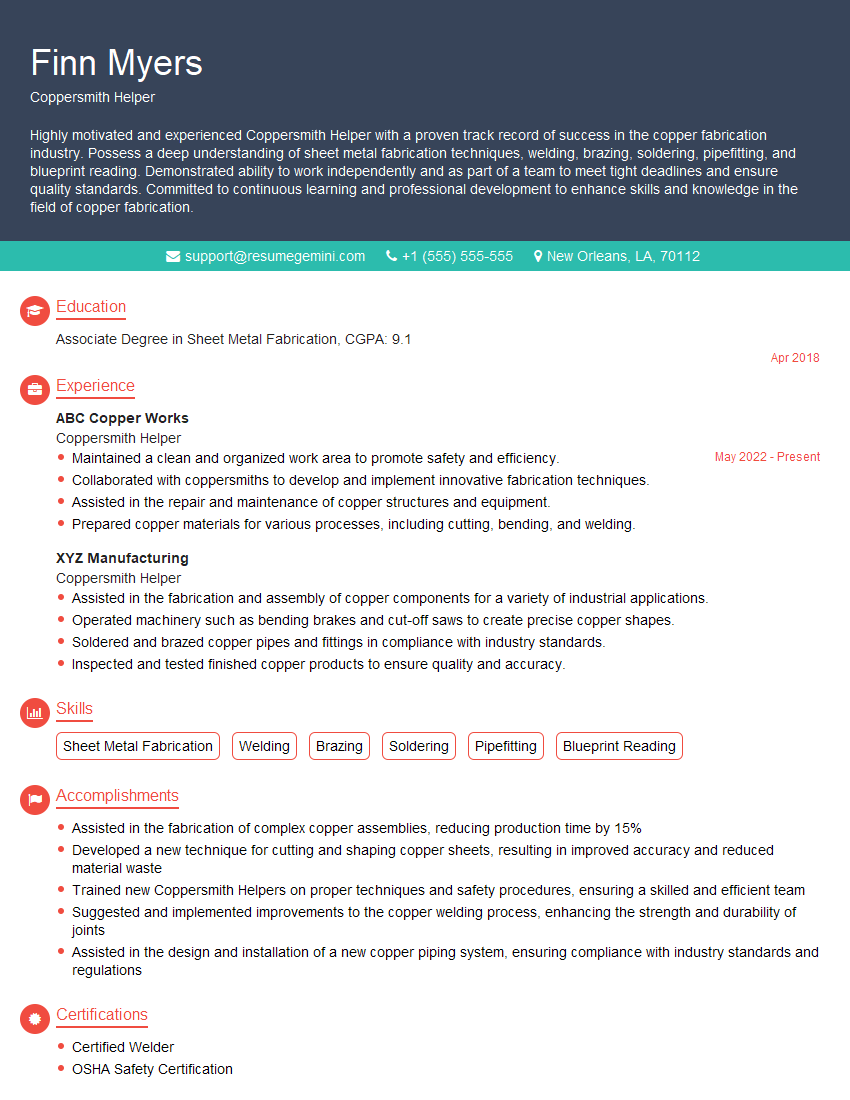

Finn Myers

Coppersmith Helper

Summary

Highly motivated and experienced Coppersmith Helper with a proven track record of success in the copper fabrication industry. Possess a deep understanding of sheet metal fabrication techniques, welding, brazing, soldering, pipefitting, and blueprint reading. Demonstrated ability to work independently and as part of a team to meet tight deadlines and ensure quality standards. Committed to continuous learning and professional development to enhance skills and knowledge in the field of copper fabrication.

Education

Associate Degree in Sheet Metal Fabrication

April 2018

Skills

- Sheet Metal Fabrication

- Welding

- Brazing

- Soldering

- Pipefitting

- Blueprint Reading

Work Experience

Coppersmith Helper

- Maintained a clean and organized work area to promote safety and efficiency.

- Collaborated with coppersmiths to develop and implement innovative fabrication techniques.

- Assisted in the repair and maintenance of copper structures and equipment.

- Prepared copper materials for various processes, including cutting, bending, and welding.

Coppersmith Helper

- Assisted in the fabrication and assembly of copper components for a variety of industrial applications.

- Operated machinery such as bending brakes and cut-off saws to create precise copper shapes.

- Soldered and brazed copper pipes and fittings in compliance with industry standards.

- Inspected and tested finished copper products to ensure quality and accuracy.

Accomplishments

- Assisted in the fabrication of complex copper assemblies, reducing production time by 15%

- Developed a new technique for cutting and shaping copper sheets, resulting in improved accuracy and reduced material waste

- Trained new Coppersmith Helpers on proper techniques and safety procedures, ensuring a skilled and efficient team

- Suggested and implemented improvements to the copper welding process, enhancing the strength and durability of joints

- Assisted in the design and installation of a new copper piping system, ensuring compliance with industry standards and regulations

Certificates

- Certified Welder

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coppersmith Helper

- Highlight your specific skills and experience in sheet metal fabrication, welding, and other relevant areas.

- Quantify your accomplishments with specific metrics whenever possible to demonstrate your impact on the job.

- Use action verbs and strong descriptions to showcase your proficiency and expertise in copper fabrication.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Coppersmith Helper Resume

- Assisted in the fabrication of complex copper assemblies, resulting in reduced production time and improved efficiency.

- Developed and implemented innovative techniques for cutting and shaping copper sheets, leading to increased accuracy and reduced material waste.

- Trained new Coppersmith Helpers on proper techniques and safety procedures, fostering a skilled and competent team.

- Suggested and implemented improvements to the copper welding process, enhancing the strength and durability of joints.

- Assisted in the design and installation of a new copper piping system, ensuring compliance with industry standards and regulations.

- Collaborated with engineers and other tradespeople to ensure proper coordination and execution of copper fabrication projects.

- Maintained a clean and organized work area, adhering to safety protocols and best practices.

- Performed regular maintenance and calibration of equipment to ensure optimal performance and safety.

Frequently Asked Questions (FAQ’s) For Coppersmith Helper

What is the primary role of a Coppersmith Helper?

The primary role of a Coppersmith Helper is to assist skilled Coppersmiths in the fabrication, installation, and repair of copper products and components.

What skills are essential for a Coppersmith Helper?

Essential skills for a Coppersmith Helper include sheet metal fabrication techniques, welding, brazing, soldering, pipefitting, and blueprint reading.

What kind of work environment can a Coppersmith Helper expect?

Coppersmith Helpers typically work in manufacturing or construction environments, often in close collaboration with other tradespeople.

What are the career advancement opportunities for a Coppersmith Helper?

With experience and additional training, Coppersmith Helpers can advance to become skilled Coppersmiths or pursue specialized roles in the copper fabrication industry.

Are there any certifications or licenses required for a Coppersmith Helper?

While not typically required, obtaining certifications or licenses in welding, brazing, or sheet metal fabrication can enhance your credibility and job prospects.

What is the salary range for a Coppersmith Helper?

Salary ranges for Coppersmith Helpers vary depending on experience, location, and industry, but typically fall within the range of $20,000 to $40,000 annually.