Are you a seasoned Die Operator seeking a new career path? Discover our professionally built Die Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

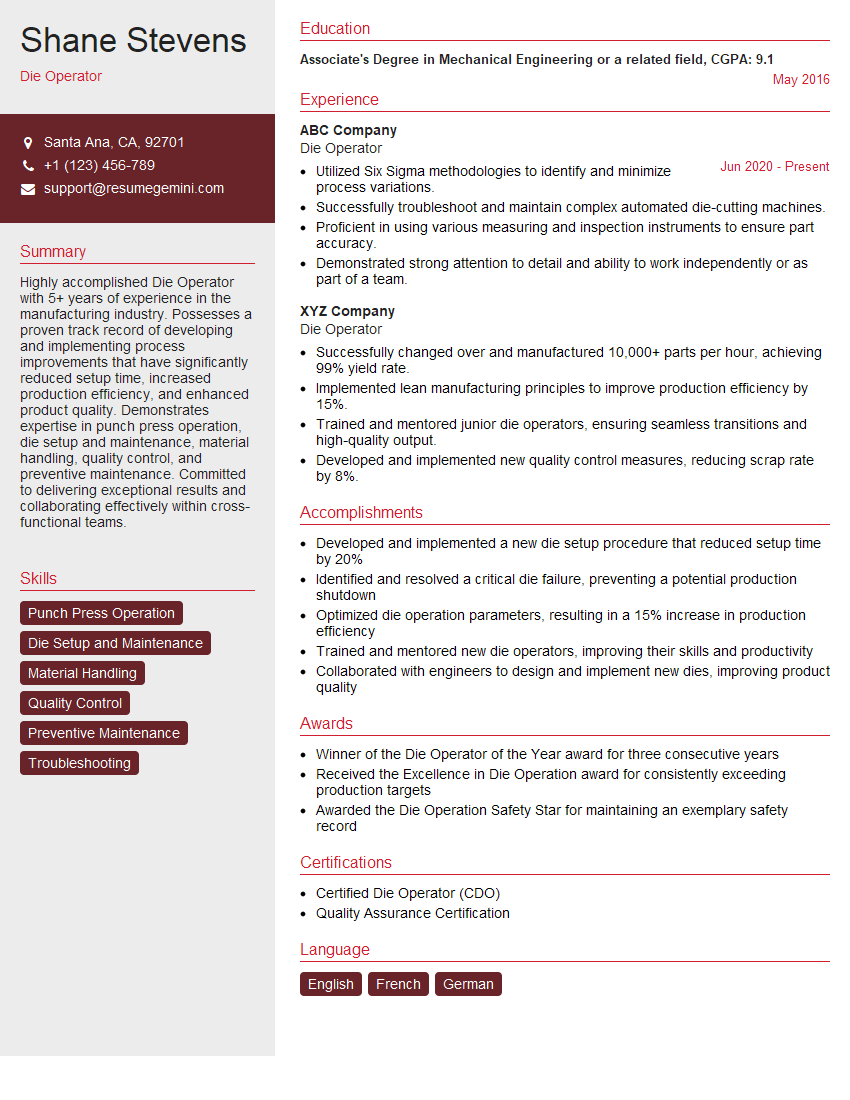

Shane Stevens

Die Operator

Summary

Highly accomplished Die Operator with 5+ years of experience in the manufacturing industry. Possesses a proven track record of developing and implementing process improvements that have significantly reduced setup time, increased production efficiency, and enhanced product quality. Demonstrates expertise in punch press operation, die setup and maintenance, material handling, quality control, and preventive maintenance. Committed to delivering exceptional results and collaborating effectively within cross-functional teams.

Education

Associate’s Degree in Mechanical Engineering or a related field

May 2016

Skills

- Punch Press Operation

- Die Setup and Maintenance

- Material Handling

- Quality Control

- Preventive Maintenance

- Troubleshooting

Work Experience

Die Operator

- Utilized Six Sigma methodologies to identify and minimize process variations.

- Successfully troubleshoot and maintain complex automated die-cutting machines.

- Proficient in using various measuring and inspection instruments to ensure part accuracy.

- Demonstrated strong attention to detail and ability to work independently or as part of a team.

Die Operator

- Successfully changed over and manufactured 10,000+ parts per hour, achieving 99% yield rate.

- Implemented lean manufacturing principles to improve production efficiency by 15%.

- Trained and mentored junior die operators, ensuring seamless transitions and high-quality output.

- Developed and implemented new quality control measures, reducing scrap rate by 8%.

Accomplishments

- Developed and implemented a new die setup procedure that reduced setup time by 20%

- Identified and resolved a critical die failure, preventing a potential production shutdown

- Optimized die operation parameters, resulting in a 15% increase in production efficiency

- Trained and mentored new die operators, improving their skills and productivity

- Collaborated with engineers to design and implement new dies, improving product quality

Awards

- Winner of the Die Operator of the Year award for three consecutive years

- Received the Excellence in Die Operation award for consistently exceeding production targets

- Awarded the Die Operation Safety Star for maintaining an exemplary safety record

Certificates

- Certified Die Operator (CDO)

- Quality Assurance Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Operator

- Highlight your technical skills and expertise in punch press operation, die setup, and maintenance.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your contributions.

- Emphasize your problem-solving abilities and experience in identifying and resolving production issues.

- Showcase your commitment to continuous improvement and willingness to learn new technologies and techniques.

Essential Experience Highlights for a Strong Die Operator Resume

- Operate punch presses and dies to produce high-quality metal components according to specifications.

- Set up and maintain dies, ensuring proper alignment and operation to minimize downtime and maximize productivity.

- Conduct preventive maintenance on equipment, including lubrication, cleaning, and minor repairs, to maintain optimal performance.

- Monitor production processes, identify potential issues, and take corrective actions to prevent breakdowns and ensure smooth operation.

- Collaborate with engineers and quality control personnel to improve die designs and optimize production parameters.

- Train and mentor new operators, sharing knowledge and best practices to enhance their skills and productivity.

- Adhere to safety regulations and industry standards, maintaining a safe and efficient work environment.

Frequently Asked Questions (FAQ’s) For Die Operator

What are the primary responsibilities of a Die Operator?

Die Operators are responsible for operating punch presses and dies to produce metal components, setting up and maintaining dies, conducting preventive maintenance, monitoring production processes, and collaborating with engineers to improve die designs and optimize production parameters.

What skills are required to be a successful Die Operator?

Successful Die Operators possess technical skills in punch press operation, die setup and maintenance, as well as problem-solving abilities, attention to detail, and a commitment to safety.

What are the career advancement opportunities for Die Operators?

Die Operators can advance to positions such as Die Setters, Tool and Die Makers, or Production Supervisors with experience and additional training.

What is the job outlook for Die Operators?

The job outlook for Die Operators is expected to grow in the coming years due to the increasing demand for skilled manufacturing workers.

How can I prepare for a career as a Die Operator?

To prepare for a career as a Die Operator, you can pursue an Associate’s Degree in Mechanical Engineering or a related field, gain experience through internships or apprenticeships, and develop your technical skills through hands-on training.

What are the safety precautions that Die Operators must follow?

Die Operators must follow safety precautions such as wearing appropriate personal protective equipment, observing lockout/tagout procedures, and adhering to established safety protocols to minimize risks in the workplace.