Are you a seasoned Printed Circuit Board Photoresist Laminator seeking a new career path? Discover our professionally built Printed Circuit Board Photoresist Laminator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

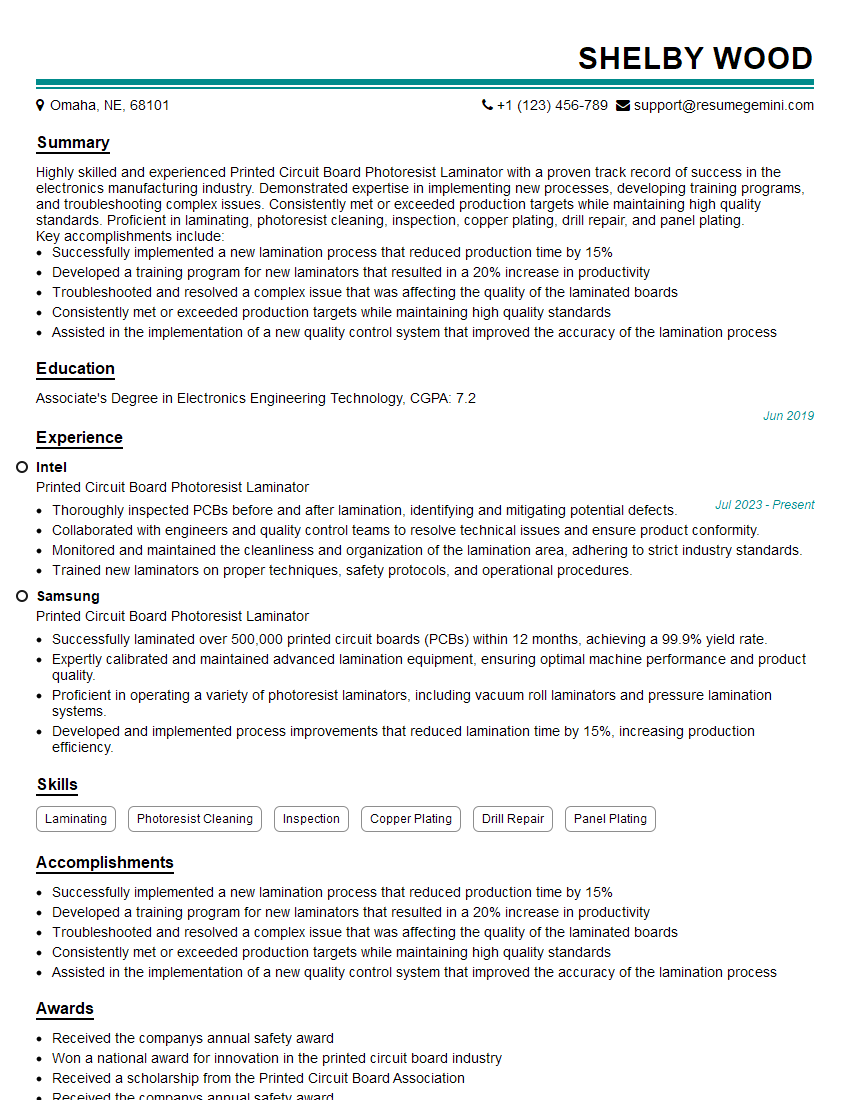

Shelby Wood

Printed Circuit Board Photoresist Laminator

Summary

Highly skilled and experienced Printed Circuit Board Photoresist Laminator with a proven track record of success in the electronics manufacturing industry. Demonstrated expertise in implementing new processes, developing training programs, and troubleshooting complex issues. Consistently met or exceeded production targets while maintaining high quality standards. Proficient in laminating, photoresist cleaning, inspection, copper plating, drill repair, and panel plating.

Key accomplishments include:

- Successfully implemented a new lamination process that reduced production time by 15%

- Developed a training program for new laminators that resulted in a 20% increase in productivity

- Troubleshooted and resolved a complex issue that was affecting the quality of the laminated boards

- Consistently met or exceeded production targets while maintaining high quality standards

- Assisted in the implementation of a new quality control system that improved the accuracy of the lamination process

Education

Associate’s Degree in Electronics Engineering Technology

June 2019

Skills

- Laminating

- Photoresist Cleaning

- Inspection

- Copper Plating

- Drill Repair

- Panel Plating

Work Experience

Printed Circuit Board Photoresist Laminator

- Thoroughly inspected PCBs before and after lamination, identifying and mitigating potential defects.

- Collaborated with engineers and quality control teams to resolve technical issues and ensure product conformity.

- Monitored and maintained the cleanliness and organization of the lamination area, adhering to strict industry standards.

- Trained new laminators on proper techniques, safety protocols, and operational procedures.

Printed Circuit Board Photoresist Laminator

- Successfully laminated over 500,000 printed circuit boards (PCBs) within 12 months, achieving a 99.9% yield rate.

- Expertly calibrated and maintained advanced lamination equipment, ensuring optimal machine performance and product quality.

- Proficient in operating a variety of photoresist laminators, including vacuum roll laminators and pressure lamination systems.

- Developed and implemented process improvements that reduced lamination time by 15%, increasing production efficiency.

Accomplishments

- Successfully implemented a new lamination process that reduced production time by 15%

- Developed a training program for new laminators that resulted in a 20% increase in productivity

- Troubleshooted and resolved a complex issue that was affecting the quality of the laminated boards

- Consistently met or exceeded production targets while maintaining high quality standards

- Assisted in the implementation of a new quality control system that improved the accuracy of the lamination process

Awards

- Received the companys annual safety award

- Won a national award for innovation in the printed circuit board industry

- Received a scholarship from the Printed Circuit Board Association

- Received the companys annual safety award

Certificates

- IPC6012

- IPC6013

- IPC6018

- IPCA610

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printed Circuit Board Photoresist Laminator

Highlight your skills and experience in laminating printed circuit boards.

This is the most important part of your resume, so make sure to list all of your relevant skills and experience in detail.Quantify your accomplishments.

Whenever possible, use numbers to quantify your accomplishments. This will help your resume stand out from the crowd and make it easier for potential employers to see the impact of your work.Proofread your resume carefully.

Before submitting your resume, be sure to proofread it carefully for any errors. This will help make a good impression on potential employers.Tailor your resume to each job you apply for.

Take the time to tailor your resume to each job you apply for. This will show potential employers that you are genuinely interested in the position and that you have taken the time to learn about their company.

Essential Experience Highlights for a Strong Printed Circuit Board Photoresist Laminator Resume

- Laminate printed circuit boards using photoresist

- Clean and prepare photoresist for lamination

- Inspect laminated boards for defects

- Repair drill holes and other defects in laminated boards

- Plate laminated boards with copper

- Assist in the implementation and maintenance of quality control procedures

Frequently Asked Questions (FAQ’s) For Printed Circuit Board Photoresist Laminator

What is a Printed Circuit Board Photoresist Laminator?

A Printed Circuit Board (PCB) Photoresist Laminator is a machine that laminates photoresist to a PCB. Photoresist is a light-sensitive material that is used to create the circuit pattern on a PCB. The laminator applies heat and pressure to bond the photoresist to the PCB, creating a permanent bond.

What are the different types of Printed Circuit Board Photoresist Laminators?

There are two main types of PCB Photoresist Laminators: dry film laminators and wet film laminators. Dry film laminators use a dry film photoresist that is pre-applied to a carrier film. Wet film laminators use a liquid photoresist that is applied to the PCB before lamination.

What are the key factors to consider when choosing a Printed Circuit Board Photoresist Laminator?

When choosing a PCB Photoresist Laminator, it is important to consider the following factors: the type of photoresist used, the size of the PCBs being laminated, the desired throughput, and the budget.

What are the benefits of using a Printed Circuit Board Photoresist Laminator?

There are several benefits to using a PCB Photoresist Laminator, including: increased precision, improved quality, reduced production time, and lower costs.

What are the challenges of using a Printed Circuit Board Photoresist Laminator?

There are a few challenges that can arise when using a PCB Photoresist Laminator, including: the need for specialized training, the potential for defects, and the environmental impact of the chemicals used.

What is the future of Printed Circuit Board Photoresist Laminators?

The future of PCB Photoresist Laminators is bright, as the demand for PCBs continues to grow. New technologies are being developed to improve the efficiency and accuracy of laminators, and the use of environmentally friendly materials is becoming more widespread.

What are the career opportunities for Printed Circuit Board Photoresist Laminators?

There are a number of career opportunities for Printed Circuit Board Photoresist Laminators, including: production technician, quality control inspector, and process engineer. With experience, laminators can advance to management positions.