Are you a seasoned Rubber Worker seeking a new career path? Discover our professionally built Rubber Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

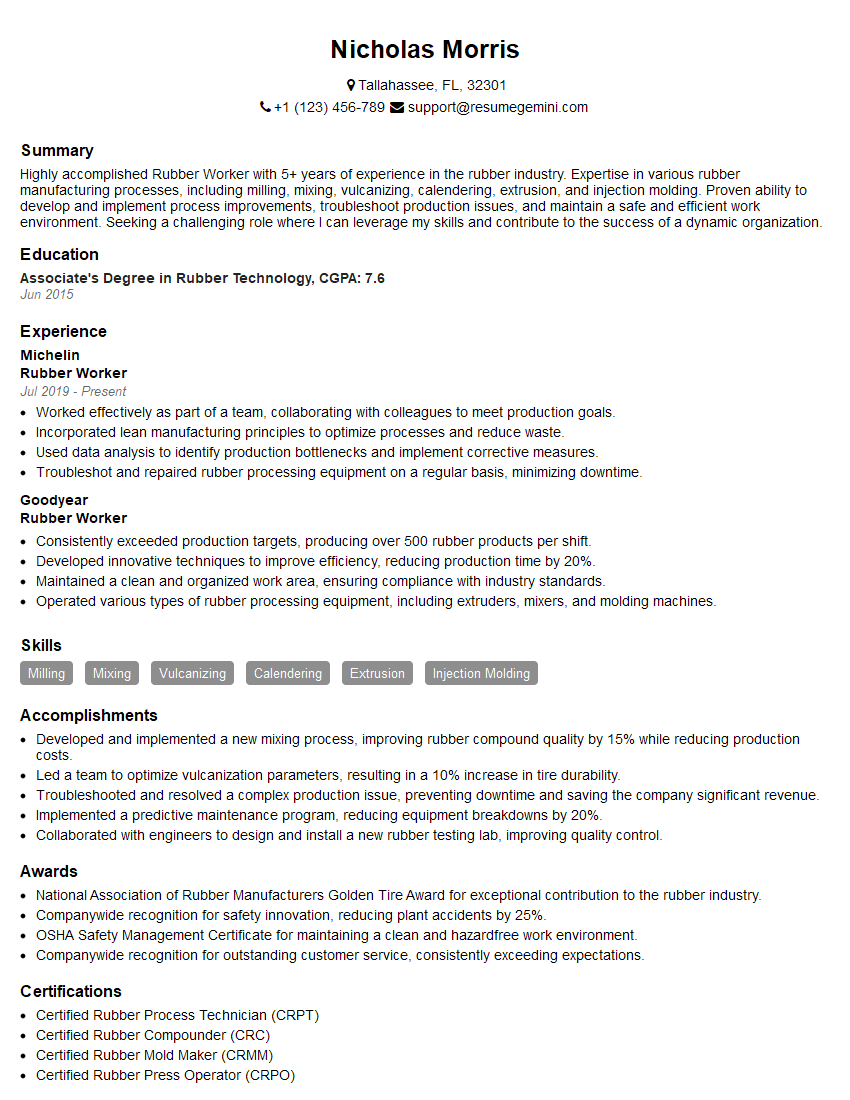

Nicholas Morris

Rubber Worker

Summary

Highly accomplished Rubber Worker with 5+ years of experience in the rubber industry. Expertise in various rubber manufacturing processes, including milling, mixing, vulcanizing, calendering, extrusion, and injection molding. Proven ability to develop and implement process improvements, troubleshoot production issues, and maintain a safe and efficient work environment. Seeking a challenging role where I can leverage my skills and contribute to the success of a dynamic organization.

Education

Associate’s Degree in Rubber Technology

June 2015

Skills

- Milling

- Mixing

- Vulcanizing

- Calendering

- Extrusion

- Injection Molding

Work Experience

Rubber Worker

- Worked effectively as part of a team, collaborating with colleagues to meet production goals.

- Incorporated lean manufacturing principles to optimize processes and reduce waste.

- Used data analysis to identify production bottlenecks and implement corrective measures.

- Troubleshot and repaired rubber processing equipment on a regular basis, minimizing downtime.

Rubber Worker

- Consistently exceeded production targets, producing over 500 rubber products per shift.

- Developed innovative techniques to improve efficiency, reducing production time by 20%.

- Maintained a clean and organized work area, ensuring compliance with industry standards.

- Operated various types of rubber processing equipment, including extruders, mixers, and molding machines.

Accomplishments

- Developed and implemented a new mixing process, improving rubber compound quality by 15% while reducing production costs.

- Led a team to optimize vulcanization parameters, resulting in a 10% increase in tire durability.

- Troubleshooted and resolved a complex production issue, preventing downtime and saving the company significant revenue.

- Implemented a predictive maintenance program, reducing equipment breakdowns by 20%.

- Collaborated with engineers to design and install a new rubber testing lab, improving quality control.

Awards

- National Association of Rubber Manufacturers Golden Tire Award for exceptional contribution to the rubber industry.

- Companywide recognition for safety innovation, reducing plant accidents by 25%.

- OSHA Safety Management Certificate for maintaining a clean and hazardfree work environment.

- Companywide recognition for outstanding customer service, consistently exceeding expectations.

Certificates

- Certified Rubber Process Technician (CRPT)

- Certified Rubber Compounder (CRC)

- Certified Rubber Mold Maker (CRMM)

- Certified Rubber Press Operator (CRPO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rubber Worker

- Highlight your technical skills and experience in rubber manufacturing processes, such as milling, mixing, vulcanizing, and extrusion.

- Showcase your ability to improve processes and increase efficiency by providing specific examples and quantifiable results.

- Emphasize your problem-solving abilities and experience in troubleshooting and resolving production issues.

- Demonstrate your commitment to safety by mentioning your knowledge of industry safety regulations and your experience in maintaining a safe work environment.

- Include keywords relevant to the rubber industry, such as rubber processing, vulcanization, and quality control.

Essential Experience Highlights for a Strong Rubber Worker Resume

- Operate and maintain rubber processing equipment, including mixers, vulcanizers, calenders, extruders, and injection molding machines

- Develop and implement new mixing processes to improve rubber compound quality while reducing production costs

- Optimize vulcanization parameters to enhance tire durability and performance

- Troubleshoot and resolve complex production issues to prevent downtime and minimize losses

- Implement predictive maintenance programs to reduce equipment breakdowns and ensure smooth operations

- Collaborate with engineers to design and install new rubber testing labs to improve quality control standards

Frequently Asked Questions (FAQ’s) For Rubber Worker

What are the primary duties of a Rubber Worker?

Rubber Workers are responsible for operating and maintaining rubber processing equipment, developing and implementing new mixing processes, optimizing vulcanization parameters, troubleshooting production issues, implementing predictive maintenance programs, and collaborating with engineers to design and install new rubber testing labs.

What skills are required to be a successful Rubber Worker?

Successful Rubber Workers possess technical skills in rubber manufacturing processes, including milling, mixing, vulcanizing, and extrusion. They are also proficient in troubleshooting and resolving production issues, and have a strong commitment to safety. Additionally, they are able to work independently and as part of a team, and have excellent communication and interpersonal skills.

What are the career prospects for Rubber Workers?

Rubber Workers with experience and expertise can advance to supervisory or management positions within the rubber industry. They may also specialize in a particular area of rubber manufacturing, such as tire production or rubber compounding. With additional education and training, Rubber Workers may also pursue careers in research and development, or in sales and marketing.

What is the typical work environment for a Rubber Worker?

Rubber Workers typically work in manufacturing plants, where they operate and maintain rubber processing equipment. They may work in a variety of settings, including production lines, laboratories, and warehouses. The work can be physically demanding and may involve exposure to chemicals and fumes. Rubber Workers must also be able to work in a fast-paced and often noisy environment.

What is the job outlook for Rubber Workers?

The job outlook for Rubber Workers is expected to be good over the next several years. The demand for rubber products is expected to grow as the economy continues to expand. However, competition for jobs may be strong, as there are a limited number of positions available. Those with the most experience and skills will have the best job prospects.

What are the educational requirements for becoming a Rubber Worker?

Most Rubber Workers have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in rubber technology or a related field. Additional training and experience in rubber manufacturing processes may also be required.